Electrophotographic photosensitive member, process cartridge, and electrophotographic apparatus

一种电子照相、感光构件的技术,应用在应用电荷图形的电记录工艺的设备、应用电荷图形的电记录工艺、光学等方向,能够解决成本提高、尺寸变大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

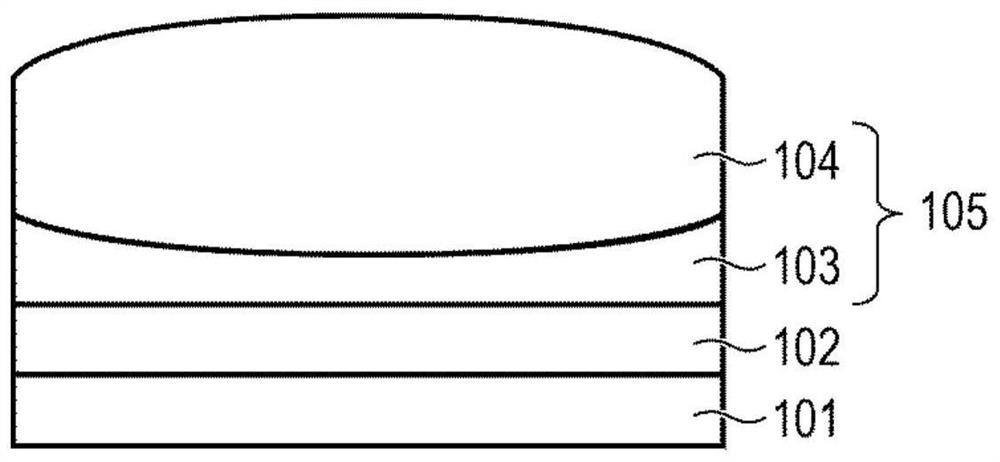

[0134] An aluminum cylinder (JIS-A3003, aluminum alloy) having a length of 260.5 mm and a diameter of 30 mm was set on a support (conductive support).

[0135] Then, prepare the following materials.

[0136] 214 parts covered with oxygen-deficient tin oxide (SnO 2 ) Titanium oxide (TiO 2 ) particles (the number average primary particle size is 200nm) as metal oxide particles

[0137] 132 parts of phenolic resin (product name: Priophene J-325) as binder resin

[0138] 40 parts methanol

[0139] 58 parts of 1-methoxy-2-propanol

[0140] Put these materials into a sand mill using 450 parts of glass beads with a diameter of 0.8mm, and perform dispersion treatment under the conditions of rotation number: 2000rpm, dispersion treatment time: 4.5 hours and set temperature of cooling water: 18°C, Thus, a dispersion liquid was obtained. The glass beads were removed from the dispersion through a sieve (pore size: 150 μm). The following materials were added to the dispersion liquid...

Embodiment 2 to 22

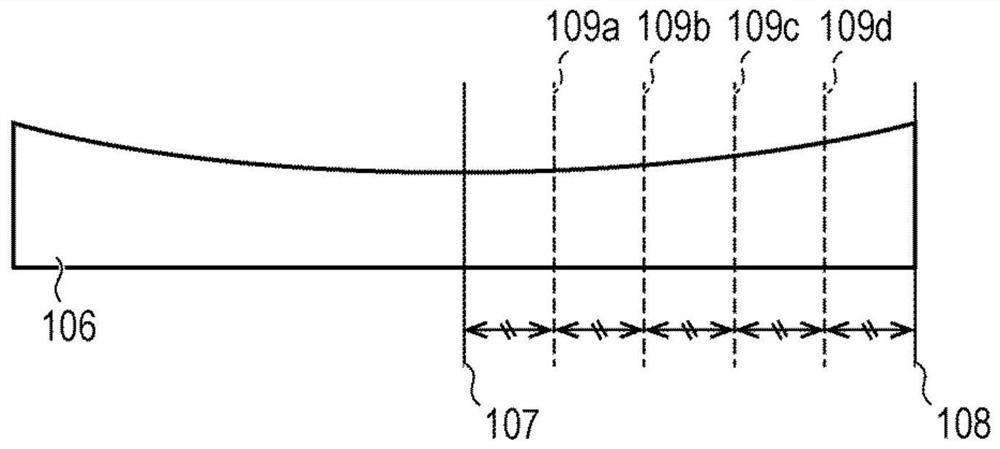

[0178] In Example 1, the film thicknesses of the charge generating layer and the charge transporting layer were set to the values shown in Table 1 by changing the lifting speed at the time of dip coating. Except for this, an electrophotographic photosensitive member was manufactured in the same manner as in Example 1, and ghost evaluation was performed similarly. Each characteristic of the obtained electrophotographic photosensitive member is shown in Table 2, and the results of ghost evaluation are shown in Table 3.

Embodiment 23

[0180] In Example 1, the content of the charge transporting substance used to form the charge transporting layer was changed from 7 parts to 5 parts, and the content of the polyester resin was changed from 10 parts to 11 parts. Except for this, an electrophotographic photosensitive member was manufactured in the same manner as in Example 1, and ghost evaluation was performed similarly. Each characteristic of the obtained electrophotographic photosensitive member is shown in Table 2, and the results of ghost evaluation are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com