Film formation device

A film-forming device and a film-forming chamber technology, which are applied in the direction of spraying devices, liquid spraying devices, and devices for coating liquid on the surface, etc., can solve the problems of more film-forming situations and difficulty in using large-area substrates, and achieve The effect of not reducing the quality of film formation and avoiding the evaporation of raw material mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]

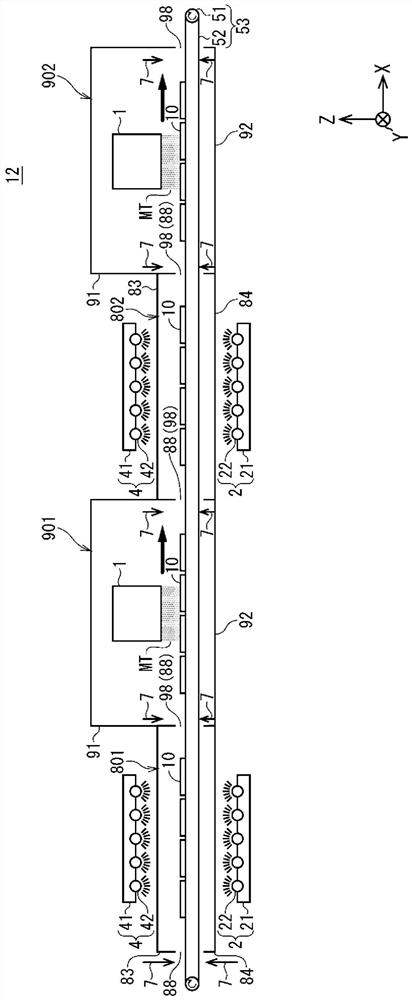

[0034] to improve Figure 7 In the prior art shown, instead of providing the heating mechanism 32 in the substrate loading table 30, an infrared light irradiator for performing a heating process of heating the substrate 10 by irradiating infrared light from an infrared lamp is separately provided as a heating mechanism. , and a structure arranged away from the substrate loading table 30 is considered as a new premise technology.

[0035] In the above-mentioned premise technology, an infrared light irradiator is used as a heating mechanism, whereby heating can be directly performed by infrared rays as electromagnetic waves without contacting the substrate 10 serving as a base material, and thus can be uniformly heated regardless of the shape of the substrate 10. heated up.

[0036] However, also in the above prerequisite technology, the raw material mist MT absorbs the infrared light irradiated from the infrared light irradiator, and the raw material mist MT is heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com