Drying method for food processing machine, and food processing machine

A technology for food processors and drying components, which is applied in the direction of dryers, drying, and heating to dry solid materials. It can solve problems such as difficult removal, peculiar smell, and poor experience, and achieve the effect of improving volatilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

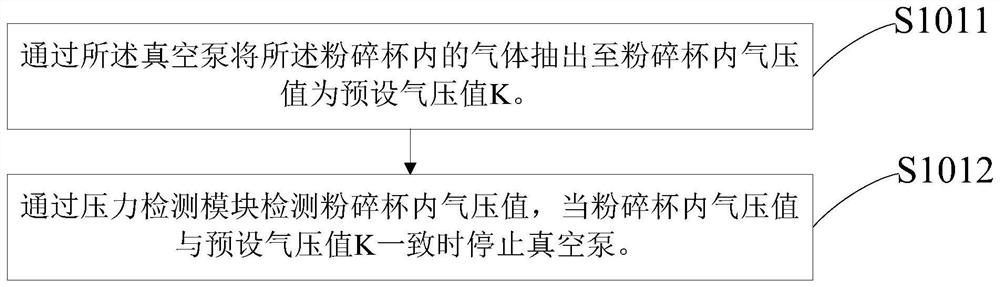

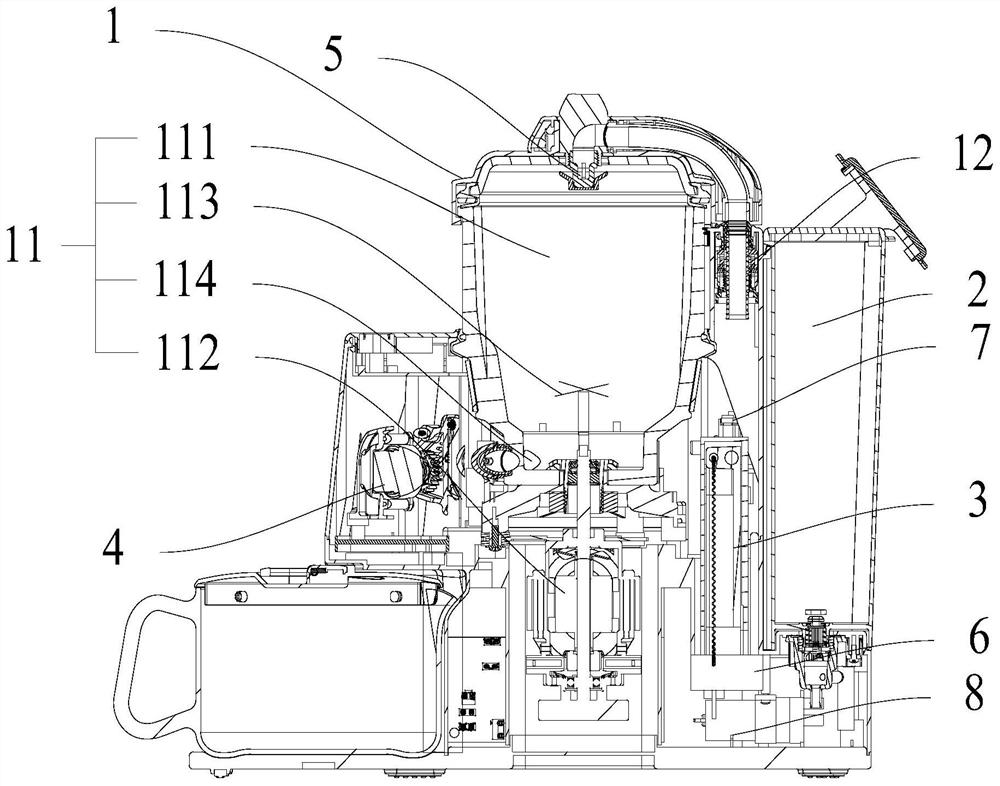

[0036] combine Figure 1 to Figure 3 As shown, in an exemplary embodiment of the present invention, the embodiment of the present invention provides a drying method for a food processor, such as image 3 As shown, the food processor includes a crushing cup 111, a drying assembly 3, a motor 112, a crushing blade 113 driven by the motor 112 in the crushing cup 111, as figure 1 As shown, the drying method includes steps S101-S103:

[0037] S101 (step a): making the inside of the crushing cup in a negative pressure state;

[0038] S102 (step b): heating the gas inside the drying component to a preset temperature T1';

[0039] S102 (step c): connecting the drying assembly to the crushing cup, so that the gas inside the drying assembly is sucked into the crushing cup.

[0040] The specific implementation process of each step will be introduced in detail below:

[0041] S101 (step a): In this scheme S101 (step a), the gas in the crushing cup is placed in a negative pressure state...

Embodiment 2

[0065] In this embodiment, on the basis of the first embodiment, an embodiment scheme for ensuring the supply of circulating gas is given.

[0066] like Figure 4 As shown, when the heated gas enters the crushing cup, in order to ensure a sufficient supply of circulating gas, the food processor also includes an air extraction component, and the step c also includes: pumping the external air of the food processor to the drying component 3 at a preset speed , in this scheme, the pumping component is the water pump 6.

[0067] When the heated gas enters the crushing cup 111, in order to replenish the cold air in real time, the gas is pumped to the drying assembly 3 by using an air pumping assembly. Preferably, the outside air enters the drying assembly 3 and the heated gas enters the crushing cup 111 The amount of gas is equal.

Embodiment 3

[0069] On the basis of Embodiment 1 and Embodiment 2, this embodiment provides a scheme of simultaneously executing step b and step c or simultaneously executing step a, step b, and step c.

[0070] In order to improve drying efficiency, step b and step c are performed simultaneously or step a, step b, and step c are performed simultaneously, so that the gas inside the drying component 3 flows into the crushing cup 111 while heating the gas, Improve the drying efficiency of the crushing cup 111.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com