Desulfurization liquid regeneration tank capable of realizing bottom horizontal jet flow.

A desulfurization liquid and regeneration tank technology, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of no desulfurization liquid mixing and stirring, large flow dead zone at the bottom of the tank, and sulfur easily deposited on the bottom of the tank, etc. , to further inhibit the shear diffusion, improve the oxidation rate, and improve the efficiency of oxidation regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

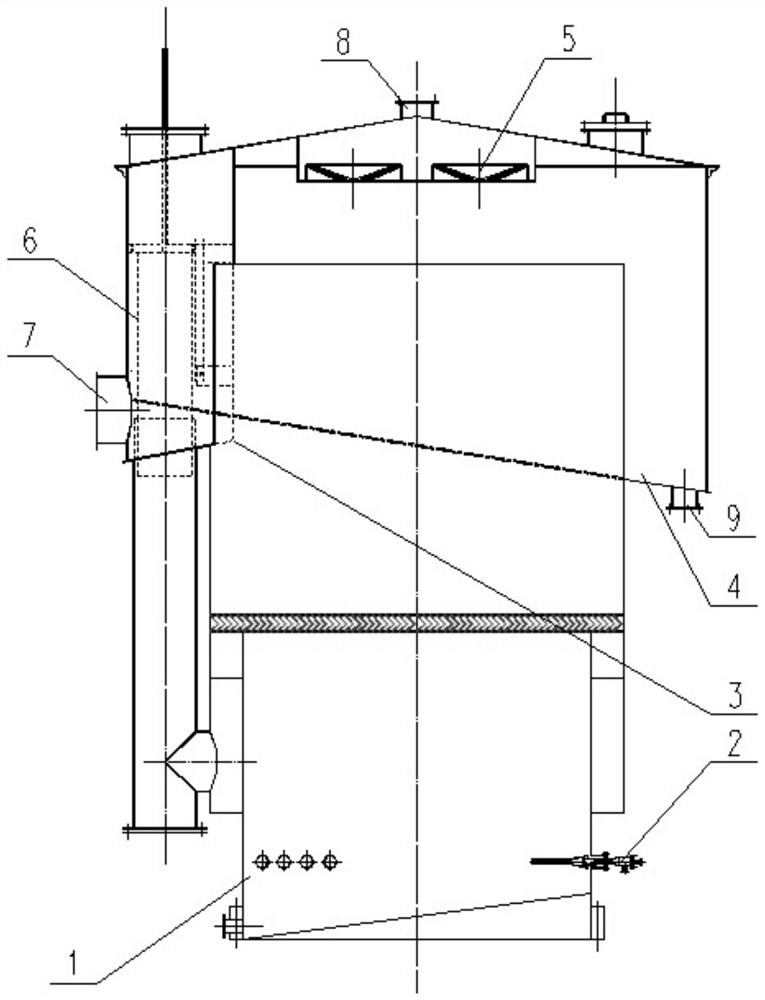

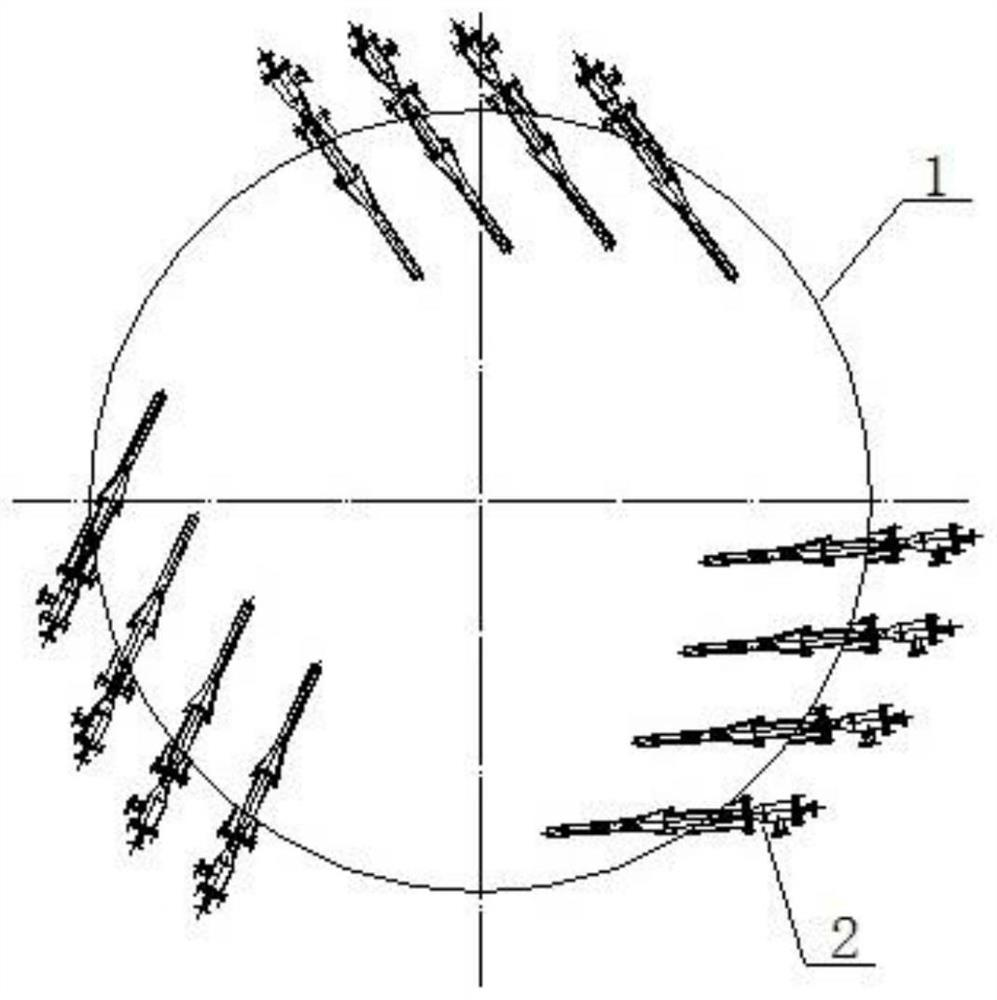

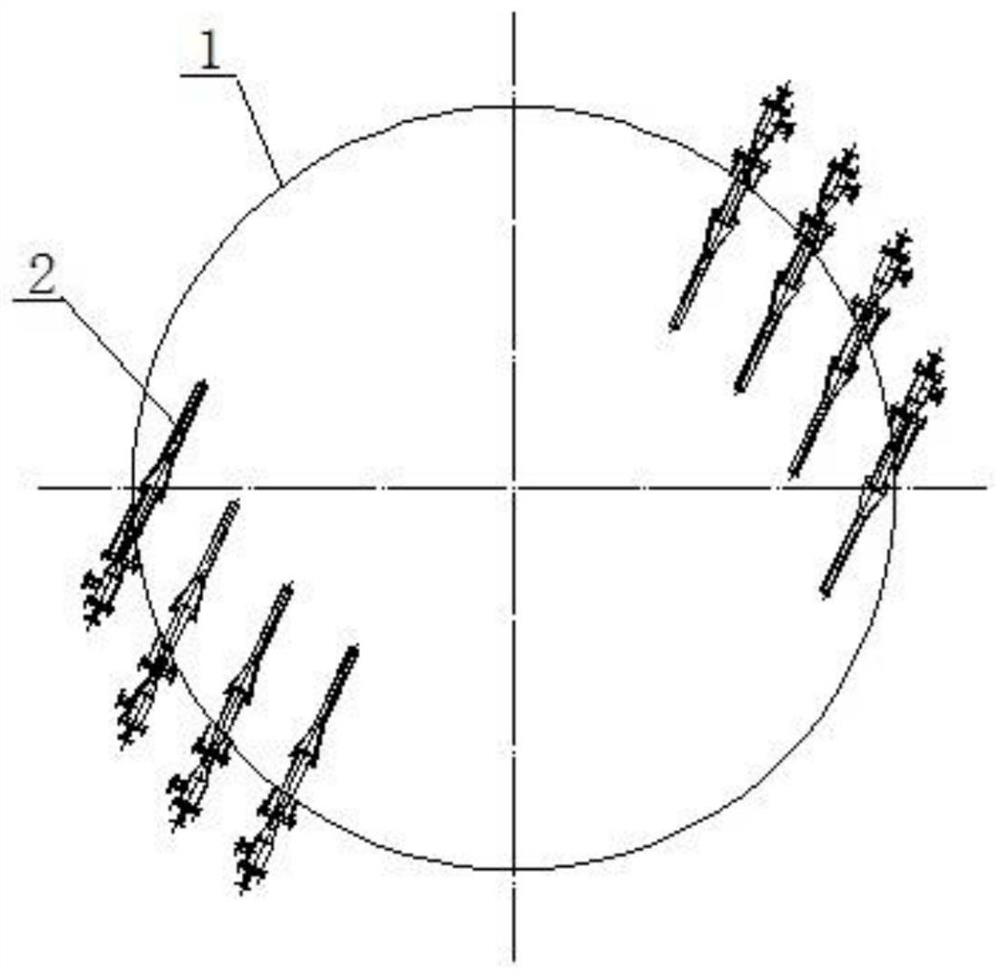

[0026] Such as figure 1 As shown, a desulfurization liquid regeneration tank with bottom horizontal jet flow according to the present invention comprises a desulfurization liquid tank 1, a foam tank 4 and a liquid level regulator 6; the foam tank 4 is arranged on the top of the desulfurization liquid tank 1, and the foam tank The diameter of 4 is greater than the diameter of desulfurization liquid tank 1, and an annular sulfur foam storage tank is formed between the two, and a sulfur foam outlet 9 is arranged at the bottom of the sulfur foam storage tank; side, the bottom of the liquid level regulator 6 communicates with the lower part of the desulfurization liquid tank 1, and the upper part of the liquid level regulator 6 passes through the foam tank 4; A group of jet ejectors, each group of jet ejectors is composed of a plurality of jet ejector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com