Catalyst for chemical looping partial oxidation of methane to syngas, preparation and application thereof

A catalyst and chemical chain technology, applied in the field of chemical chain partial oxidation methane to synthesis gas catalyst, can solve the problem of low selectivity of synthesis gas, and achieve high reactivity and excellent universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

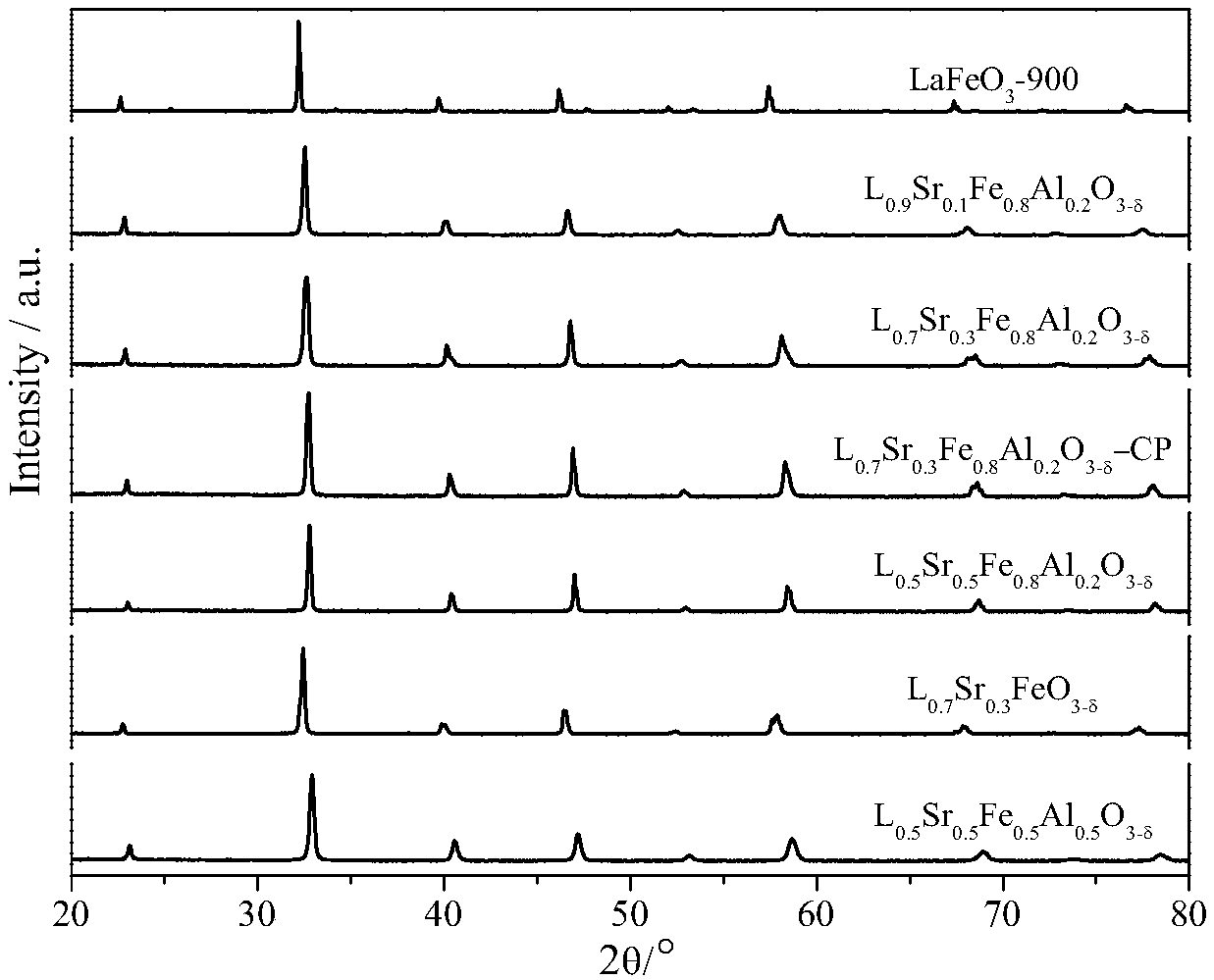

[0028]Adopt sol-gel method, the La of stoichiometric ratio, Sr, Fe, Al nitrate precursor (the amount of cationic total substance is 20mmol) is added in the citric acid solution of 100ml concentration 0.4mol / L, with concentration 28% Ammonia to adjust the pH to 7. The above solution was evaporated to dryness in a water bath at 80°C to a gel state, dried at 150°C for 12 hours, and calcined at 1200°C for 4 hours to obtain La 1-x Sr x Fe 1- y Al y o 3-δ composite oxide catalyst.

[0029] Using the co-precipitation method, the stoichiometric ratio of La, Sr, Fe, Al nitrate precursors (the amount of the total cationic substance is 20mmol) was added to 100ml deionized water, heated to 60°C in a water bath, fully stirred and dissolved, and quickly added to Ammonium carbonate solution with a concentration of 1mol / L was added to the solution, the pH was 7, stirred rapidly, left to age, filtered, washed, dried at 80°C for 12h, and roasted at 1200°C or 900°C (Example 1) for 4h to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com