Light bulletproof composite destroy-resistant plate for vehicle and preparation method of light bulletproof composite destroy-resistant plate

A lightweight and bulletproof technology, applied to the structure of armor plates, etc., can solve the problems of large thickness, incompatible with the lightweight development of armored vehicles, and heavy weight, so as to achieve the safety of protection, improve maneuverability and payload, and reduce weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

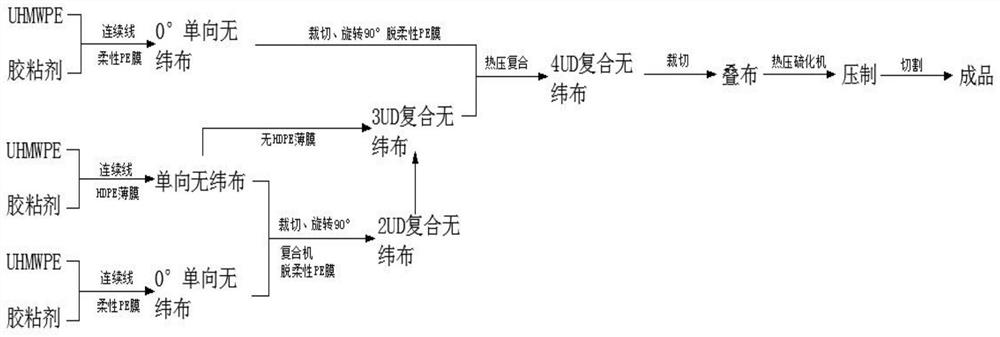

[0037] This embodiment provides a lightweight bulletproof composite anti-destruction board for vehicles, the process is as follows figure 1 As shown, the composite anti-destruction board is made of UHMWPE fiber material and adhesive.

[0038] In this embodiment, the UHNWPE fiber has a fineness of 1100-1200D and a strength of not less than 35cn / dten.

[0039] In this example, the modulus of the ultra-high molecular weight polyethylene fiber is 1470 cn / dtex.

[0040] In this example, the adhesive uses acrylic acid modified water-based polyurethane glue, and the specific preparation method is as follows:

[0041]By adding polytetramethylene ether glycol PTMEG, 2,2-dimethylolpropionic acid (DMPA), 1,4-dihydroxybutane, dicyclohexylmethane-4,4-diisocyanate (HMDI), Accurately weigh and add to the reaction kettle one by one, start stirring, slowly heat the mixture in the reaction kettle to 70.0°C, and then add 2 drops of catalyst;

[0042] The temperature of the reaction kettle is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com