Drag reducing agent and preparation method thereof

The technology of a drag reducing agent and an initiator is applied in the field of drag reducing agent and its preparation, which can solve the problems of poor water solubility, high cost, complicated synthesis operation of drag reducing agent, etc., achieves good stability, reduces preparation cost, and improves fracturing The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] In this step, NaOH solution can be used to adjust the pH of the aqueous solution. Further, when water is conditioned by NaOH solution

[0063] It should be noted that the total monomer is a general term for the monomers other than water in the aqueous solution. For example, in preparing drop

[0065] The initiator is used to initiate random copolymerization of the components in the aqueous solution to obtain a polymer. in a possible

[0067] It should be noted that the quality of the initiator added should be appropriate, not too much or too little. when the join triggers

[0068] It should be noted that, in this step, preferably, the reaction temperature is 50~60 ℃, and the reaction time is 5~7h.

Embodiment 1

[0077] The present embodiment provides a drag-reducing agent, and its drag-reducing rate is measured. Wherein, the preparation method of this resistance reducing agent

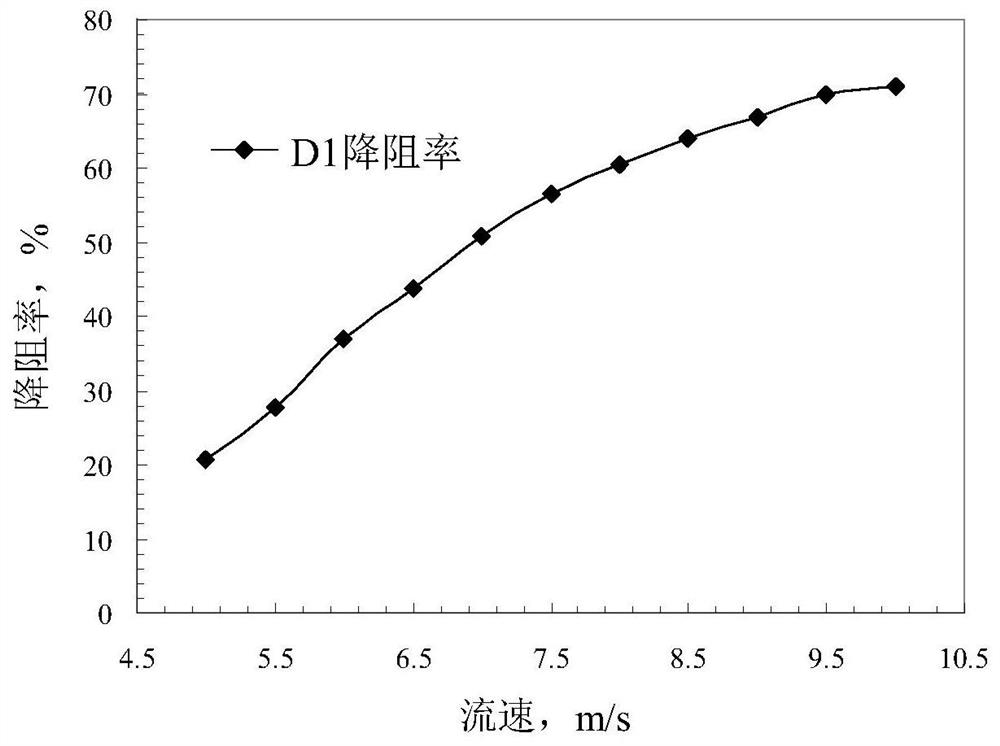

[0081] As can be seen from Figure 1: with the increase of the flow rate, the resistance reduction rate of D1 is also increasing. And when the flow rate is small, the resistance is reduced

Embodiment 2

[0083] The present embodiment provides a drag-reducing agent, and its drag-reducing rate is measured. Wherein, the preparation method of this resistance reducing agent

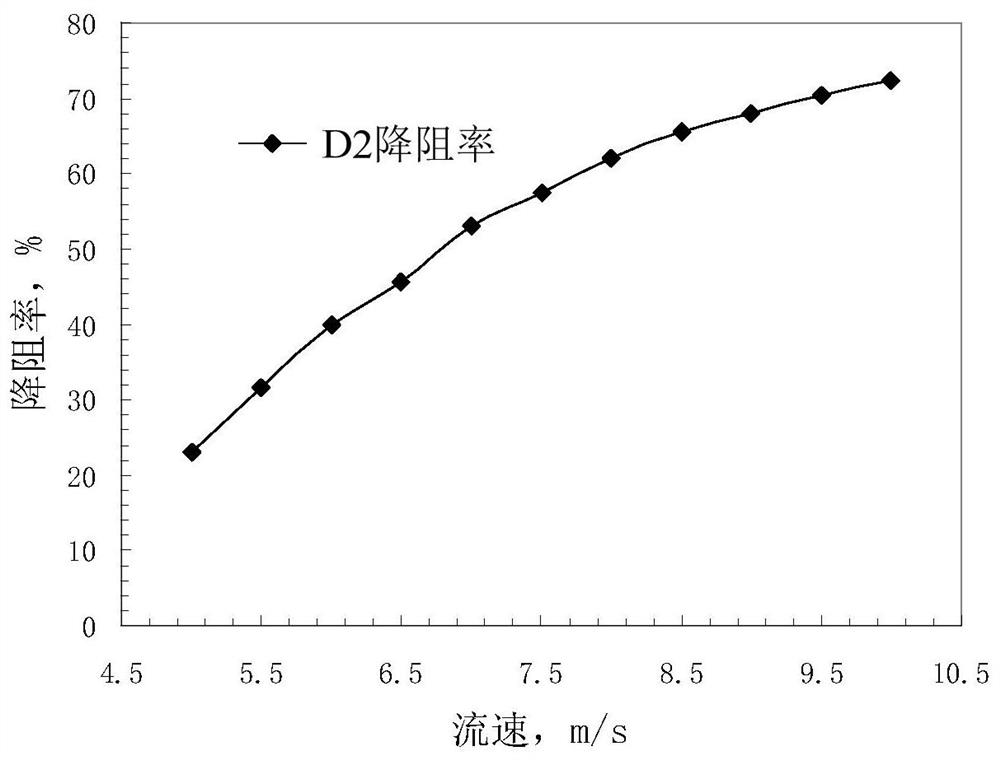

[0087] As can be seen from Figure 2: as the flow rate increases, the resistance reduction rate of D2 also increases. And when the flow rate is small, the resistance is reduced

PUM

| Property | Measurement | Unit |

|---|---|---|

| resistance reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com