Method for extracting and refining crocodile oil

A kind of crocodile oil and crocodile technology, applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of low extraction efficiency, loss of active ingredients, poor stability, etc., to achieve wide market application, remove fishy smell, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

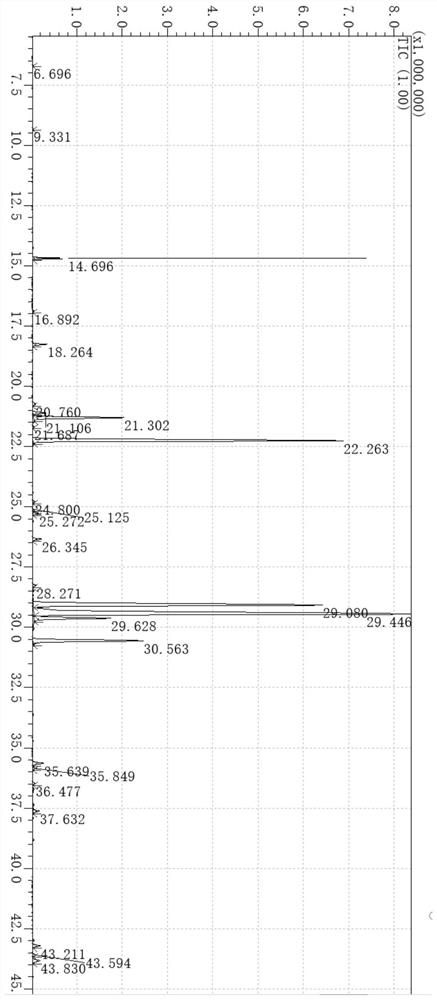

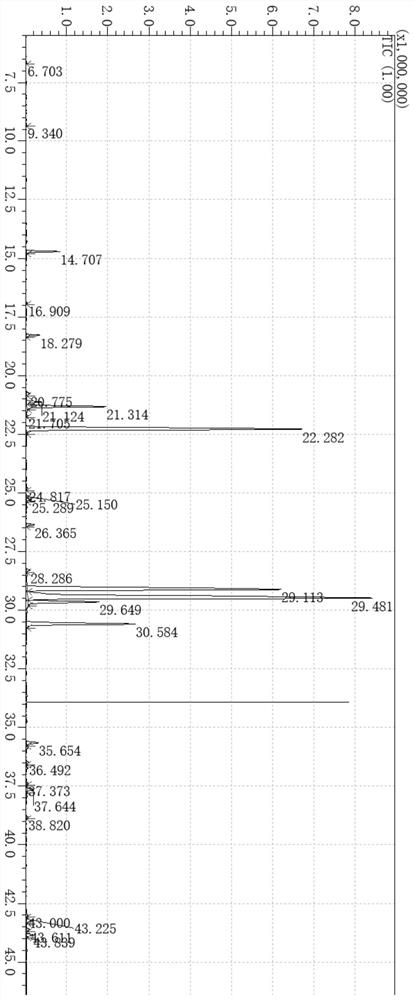

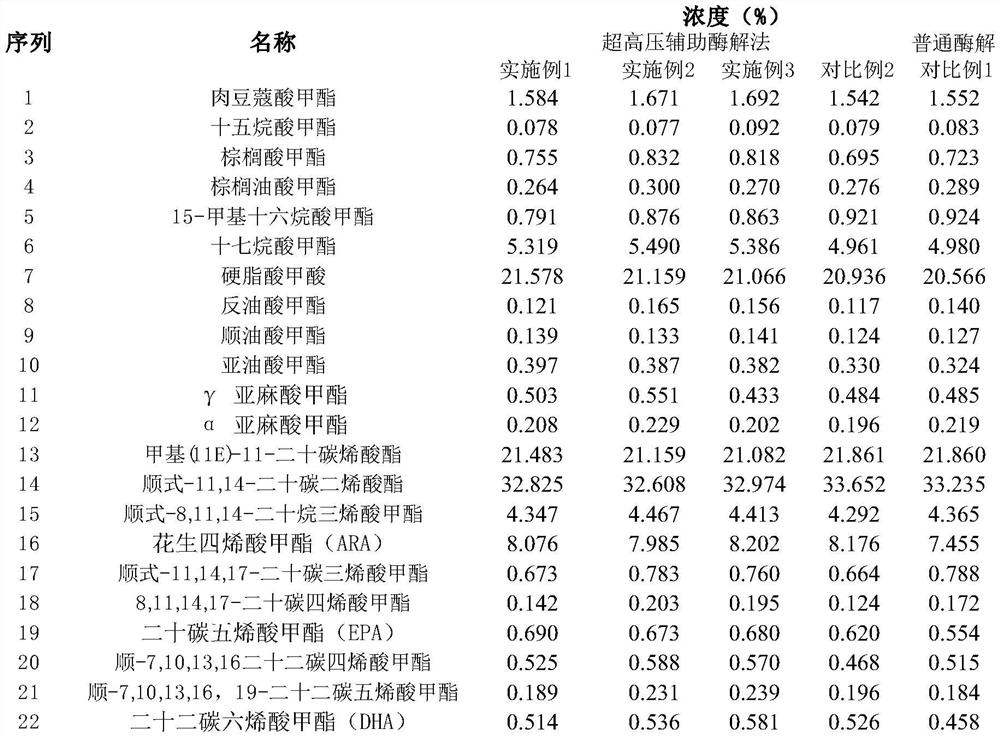

Embodiment 1

[0023] (1) Pretreatment of crocodile oil adipose tissue: mix crocodile fat and water in a ratio of 1:1, chop and mix into a minced shape;

[0024] (2) Ultra-high pressure assisted enzymatic hydrolysis: the mixed solution is placed in an ultra-high pressure container, and crocodile oil is extracted by ultra-high pressure assisted enzymatic hydrolysis. The ultra-high pressure assisted enzymatic hydrolysis conditions are 200MPa, 60°C, 4h, and the selected enzyme is a compound enzyme ( Keratinase: lipase = 1:1), pressurize and inactivate the enzyme after the enzymolysis is completed, the condition is 500MPa, 25min, and separate the different phases of meat residue, oil and water from the enzymolysis solution to obtain the crude crocodile oil;

[0025] (3) Decolorization and deodorization: use a steam generator to pass steam into the crude oil for 30 minutes, the steam flow rate is 60m / s, and the rotation speed is 150r / min, condense and vacuumize to remove the fishy smell, and then ...

Embodiment 2

[0029] (1) Pretreatment of crocodile oil adipose tissue: mix crocodile fat and water in a ratio of 1:1, chop and mix into a minced shape;

[0030] (2) Ultra-high pressure assisted enzymolysis: the mixed solution is placed in an ultra-high pressure container, and the crocodile oil is extracted by the ultra-high pressure assisted enzymolysis method. The ultra-high pressure assisted enzymolysis condition is 250MPa, 55°C, 5h, and the selected enzyme is a compound enzyme ( Keratinase: lipase=1.5:1), pressurize and inactivate the enzyme after the end of enzymolysis, the condition is 450MPa, 30min, and separate the different phases of meat residue, oil and water from the enzymolysis solution to obtain the crude crocodile oil;

[0031] (3) Decolorization and deodorization: use a steam generator to pass steam into the crude oil for 30 minutes, the steam flow rate is 70m / s, and the rotation speed is 200r / min, condense and vacuumize to remove the fishy smell, and then separate oil and wat...

Embodiment 3

[0035] (1) Pretreatment of crocodile oil adipose tissue: mix crocodile fat and water in a ratio of 1:1, chop and mix into a minced shape;

[0036] (2) Ultra-high pressure assisted enzymatic hydrolysis: the mixed solution is placed in an ultra-high pressure container, and crocodile oil is extracted by ultra-high pressure assisted enzymatic hydrolysis. The ultra-high pressure assisted enzymatic hydrolysis conditions are 280MPa, 65°C, 4h, and the selected enzyme is a compound enzyme ( Keratinase: lipase = 2:1), pressurize and deactivate the enzyme after the enzymolysis is completed, the condition is 500MPa, 25min, and separate the different phases of meat residue, oil and water from the enzymolysis solution to obtain the crude crocodile oil;

[0037] (3) Decolorization and deodorization: use a steam generator to pass steam into the crude oil for 30 minutes, the steam flow rate is 50m / s, and the rotation speed is 120r / min, condense and vacuumize to remove the fishy smell, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com