Flexible stress sensor and preparation method thereof

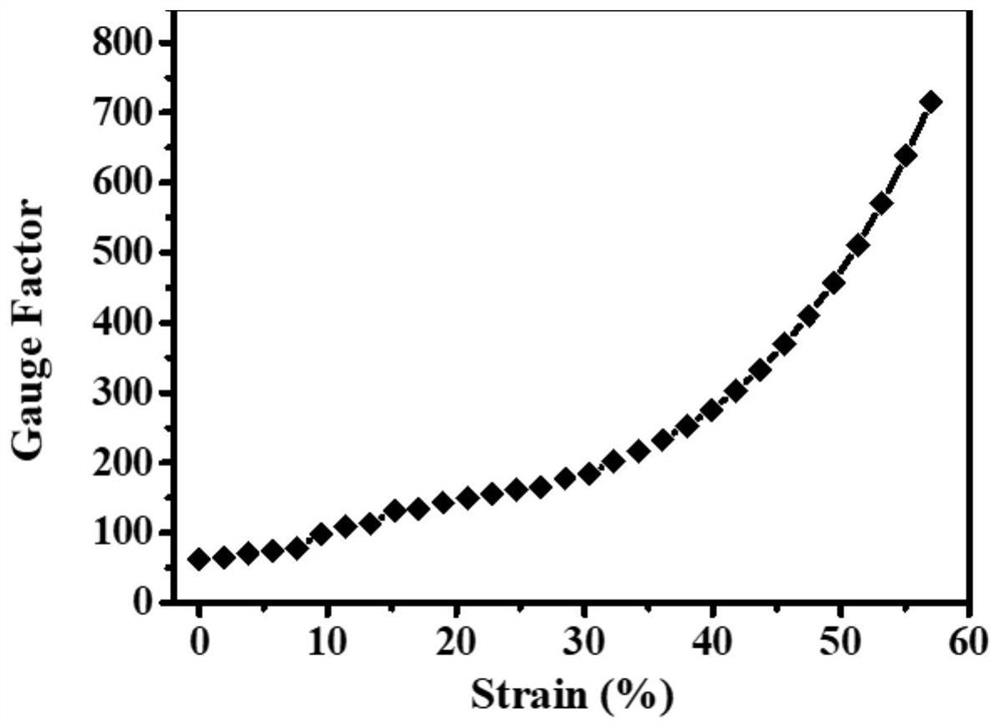

A stress sensor, a flexible technology, applied in the field of sensors, can solve the problems of exceeding the measurable range of the sensor, poor response sensitivity of micro stress, etc., and achieve the effect of excellent response sensitivity, simple cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

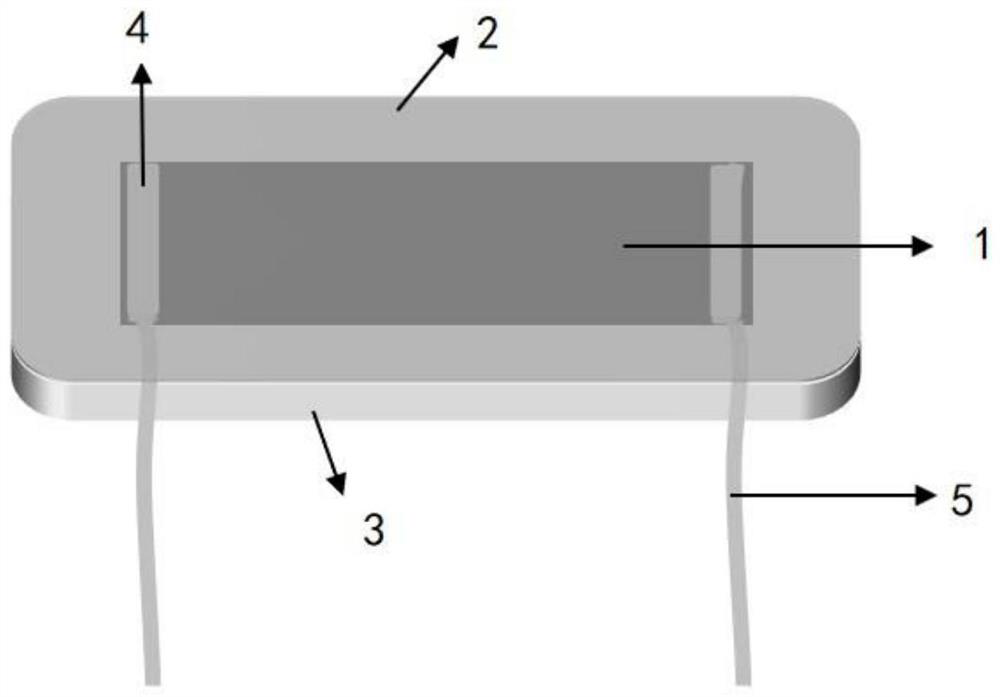

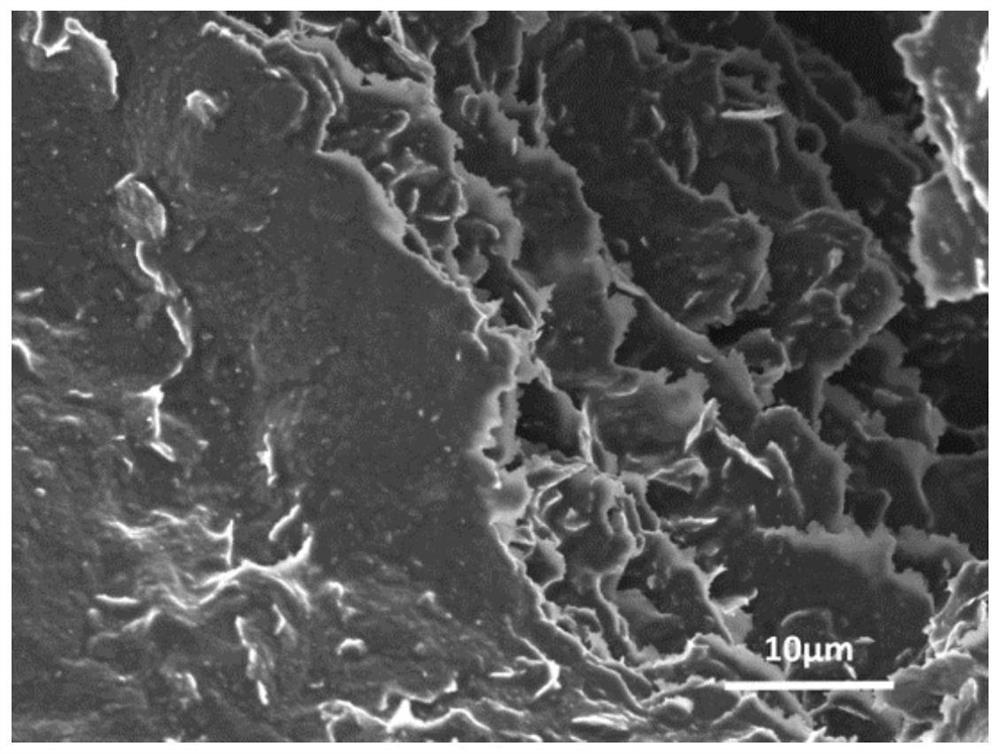

[0032]A graphene ink composed of highly conductive thin-layer graphene microchips is coated on the lower flexible polymer substrate, and the graphene ink is naturally dried into a graphene film. The diameter of the highly conductive thin-layer graphene microplates is about 2 μm. Coat the two ends of the graphene film with silver paste, take the first wire and the second wire, and glue one end of the first wire to the silver paste coated on one end of the graphene film, and the other end of the first wire Leading to the outside of the flexible packaging layer; bonding one end of the second wire to the silver paste coated on the other end of the graphene film, and leading the other end of the second wire to the outside of the flexible packaging layer. The upper flexible polymer substrate is used to insulate and encapsulate the naturally air-dried graphene film and electrodes; the insulating encapsulation includes the following process: bonding one end of the first wire to the silver p...

Embodiment 2

[0034]A graphene ink composed of highly conductive thin-layer graphene microchips is coated on the lower flexible polymer substrate, and the graphene ink is naturally dried into a graphene film. The diameter of the highly conductive thin-layer graphene microchip is 5μm. Coat the two ends of the graphene film with silver paste, take the first wire and the second wire, and glue one end of the first wire to the silver paste coated on one end of the graphene film, and the other end of the first wire Leading to the outside of the flexible packaging layer; bonding one end of the second wire to the silver paste coated on the other end of the graphene film, and leading the other end of the second wire to the outside of the flexible packaging layer. The upper flexible polymer substrate is used to insulate and encapsulate the naturally air-dried graphene film and electrodes; the insulating encapsulation includes the following process: bonding one end of the first wire to the silver paste coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gauge factor | aaaaa | aaaaa |

| gauge factor | aaaaa | aaaaa |

| gauge factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com