Device for detecting deformation of motor wave gasket and pull-down mechanism

A pull rod and tension sensor technology is applied in the field of equipment and pull-down mechanisms for detecting the deformation of motor wave pads, which can solve the problems of low accuracy of detection results and inability to simulate the state of the wave pad very well, so as to improve product assembly quality and reduce The outflow of defective products and the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

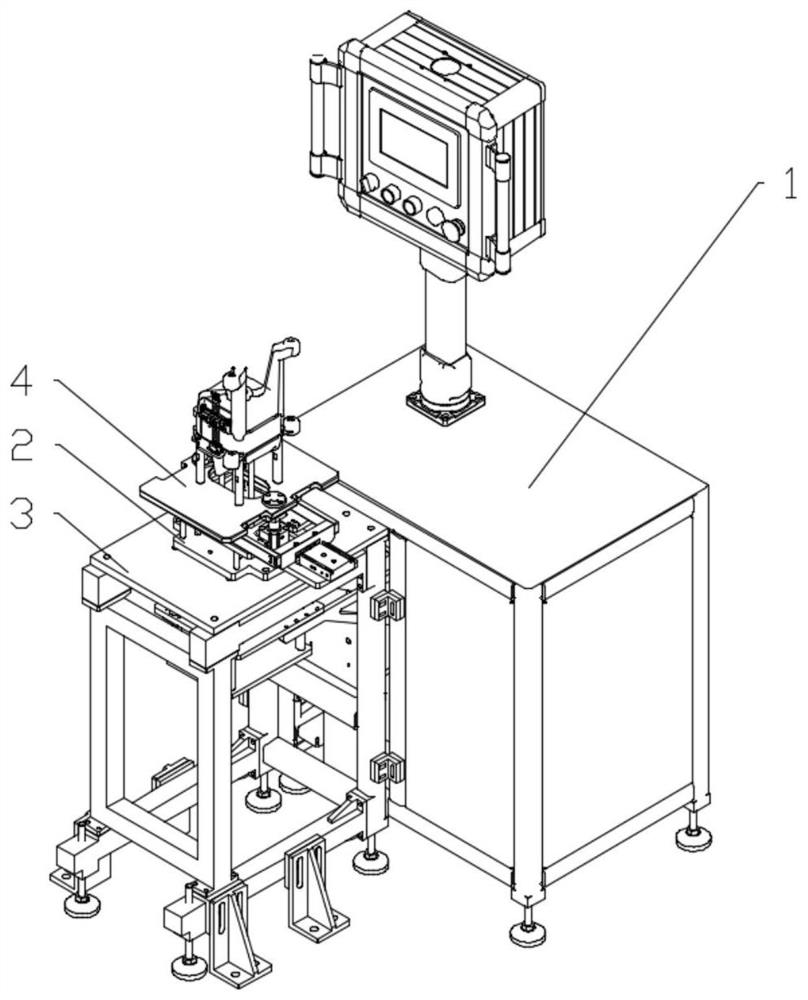

[0045] combine figure 1As shown, a device for detecting the deformation of a motor wave gasket disclosed in this embodiment includes a frame 1, a tooling plate 4, a lifting mechanism 2 and a pull-down mechanism 3, and the lifting mechanism 2 and the pull-down mechanism 3 are located at the On the frame 1, a motor 6 is fixed on the tooling plate 4, and the wave gasket quality inspection is performed on the motor through the mutual cooperation of the lifting mechanism 2 and the pull-down mechanism 3.

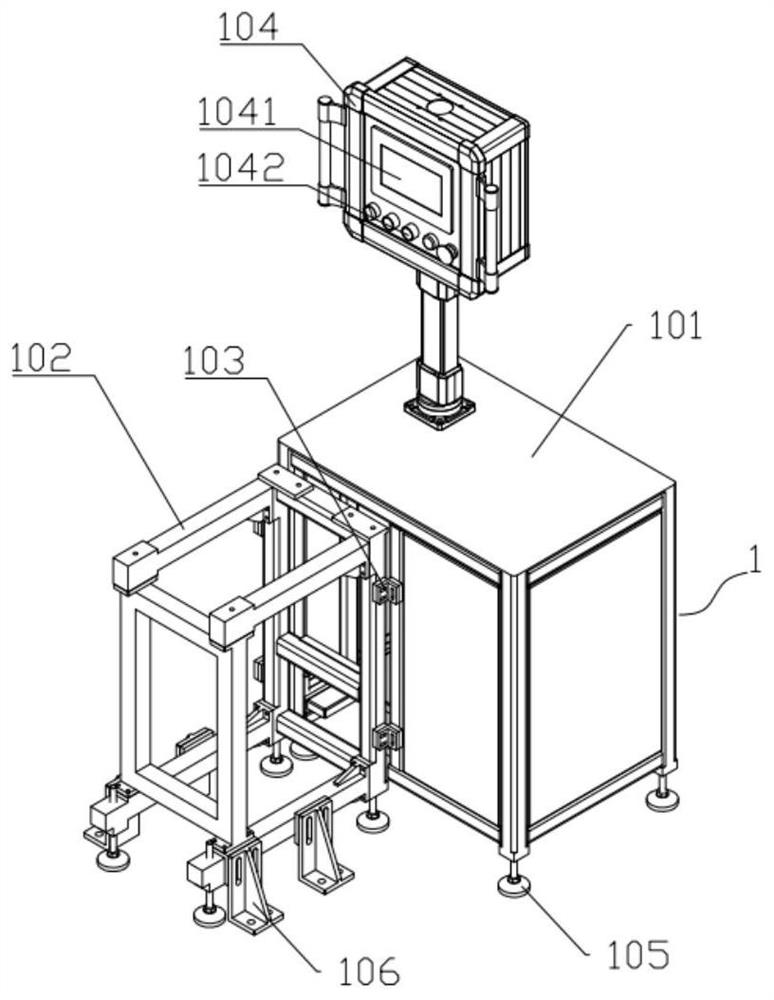

[0046] combine figure 2 As shown, the frame 1 adopts a plurality of square tubes welded to form a frame structure, and foot cups 105 are provided at the four corners of the bottom surface of the frame structure. The frame 1 includes a first bracket 101 and a second bracket 102. A bracket 101 is fixedly connected to a second bracket 102 through a connecting piece 103 .

[0047] The side of the first bracket 101 is sealed with a thin steel plate, the inside of the first bracket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com