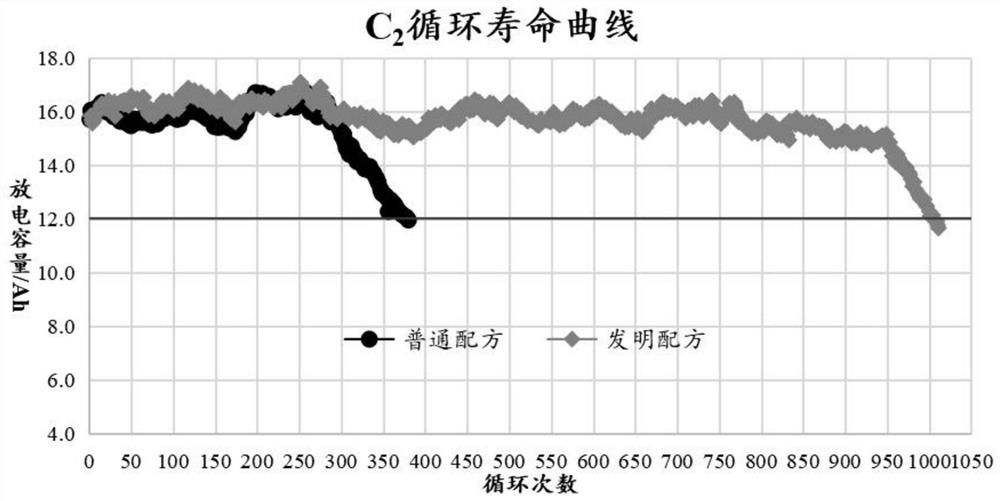

Long-life silicon-based bipolar lead storage battery positive electrode lead paste and preparation method thereof

A technology for lead-acid batteries and positive electrode paste, which is applied to batteries with bipolar electrodes, lead-acid batteries, battery electrodes, etc., and can solve problems such as poor corrosion resistance of lead-calcium alloys, limited use of strength, softening and falling off of lead paste, etc. , to achieve the effect of simple preparation method, ensuring the quality of lead paste, and improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Long-life silicon-based bipolar lead storage battery positive electrode paste, the positive electrode paste formula includes the following components: lead powder, short fibers, graphite powder, SnSO 4 、Ti 4 o 7 , Sb 2 o 3 , 4PbO·PbSO 4 , sodium perborate, dilute sulfuric acid, deionized water; short fiber is 0.5% of the weight of lead powder, graphite powder is 2% of the weight of lead powder, Sb 2 o 3 0.03% of lead powder weight, 4BS 0.5% of lead powder weight, SnSO 4 0.03% of the weight of lead powder, Ti 4 o 7 0.1% of the weight of the lead powder, deionized water is 9% of the weight of the lead powder, dilute sulfuric acid is 8% of the weight of the lead powder, sodium perborate is 0.01% of the weight of the lead powder, and the balance is the lead powder.

[0027] The density of the dilute sulfuric acid is 1.325~1.400g / cm 3 The oxidation degree of the described lead powder is 72%, the content of iron, manganese, copper and chlorine in the described lead p...

Embodiment 2

[0033] Long-life silicon-based bipolar lead storage battery positive electrode paste, the positive electrode paste formula includes the following components: lead powder, short fibers, graphite powder, SnSO 4 、Ti 4 o 7 , Sb 2 o 3 , 4PbO·PbSO 4 , sodium perborate, dilute sulfuric acid, deionized water; short fiber is 1.5% of the weight of lead powder, graphite powder is 5% of the weight of lead powder, Sb 2 o 30.1% of the weight of lead powder, 4PbO·PbSO 4 1.5% by weight of lead powder, SnSO 4 0.1% by weight of lead powder, Ti 4 o 7 0.3% of the lead powder weight, deionized water is 11% of the lead powder weight, dilute sulfuric acid is 12% of the lead powder weight, sodium perborate is 0.03% of the lead powder weight, and the balance is lead powder.

[0034] The density of the dilute sulfuric acid is 1.325~1.400g / cm 3 The oxidation degree of the described lead powder is 72%, the content of iron, manganese, copper and chlorine in the described lead powder is lower tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com