Acoustic-magnetic coupling cavitation auxiliary liquid jet polishing device and using method

A technology of auxiliary liquid and acousto-magnetic coupling, which is applied in the direction of explosion generation devices, abrasive jet machine tools, polishing compositions containing abrasives, etc., can solve the problems of insufficient impact energy of cavitation bubbles and low efficiency of bubble transport, and avoid Early collapse, compact structure, convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

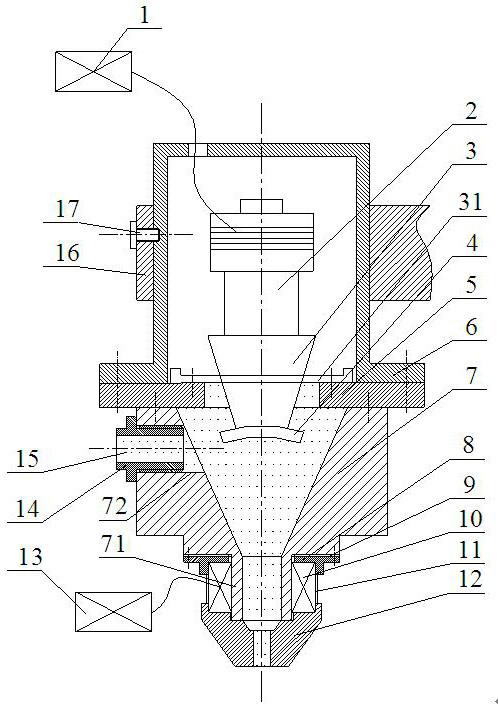

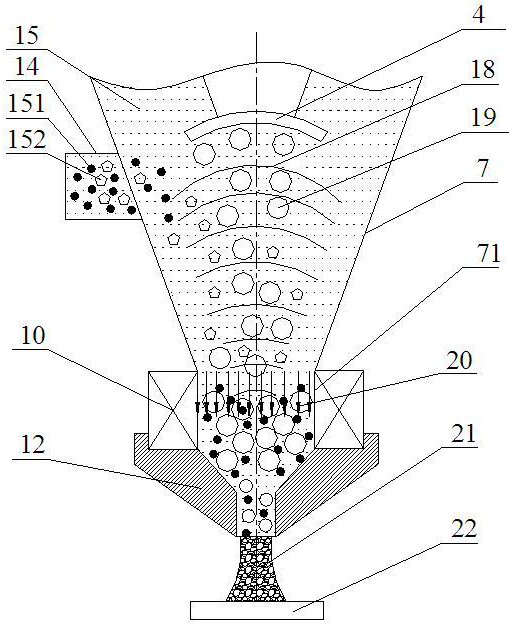

[0025] Such as figure 1 , the present invention provides an acoustomagnetic coupling cavitation auxiliary liquid jet polishing device, comprising an ultrasonic generator 1, a piezoelectric transducer 2, a horn 3, an acoustic lens 4, a chamber cover 5, an outer sleeve 6, a cone Shaped cavity 7, electromagnetic coil holder 8, gasket 9, electromagnetic coil 10, magnetic isolation sleeve 11, jet nozzle 12, magnetic field power supply 13, liquid inlet joint 14, polishing liquid 15, machine tool fixture 16, fastening bolt 17.

[0026] The ultrasonic generator 1 is connected to the piezoelectric transducer 2 through a wire; the piezoelectric transducer 2 is connected to the tail end of the horn 3 through a stud; the head end of the horn 3 is connected to the acoustic lens 4 are connected by studs.

[0027] The horn 3 is also provided with a flange 31 at the position where the displacement node is zero; the flange 31 of the horn is connected to the cavity cover 5 by bolts; the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com