Method for preparing lithium hydroxide by taking lithium-containing fluorination slag as raw material

A lithium hydroxide and lithium fluoride slag technology, applied in the direction of lithium oxide;/hydroxide, etc., can solve the problems of slow pulping rate, slow fusion rate of pulp and conversion agent, and reduced reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

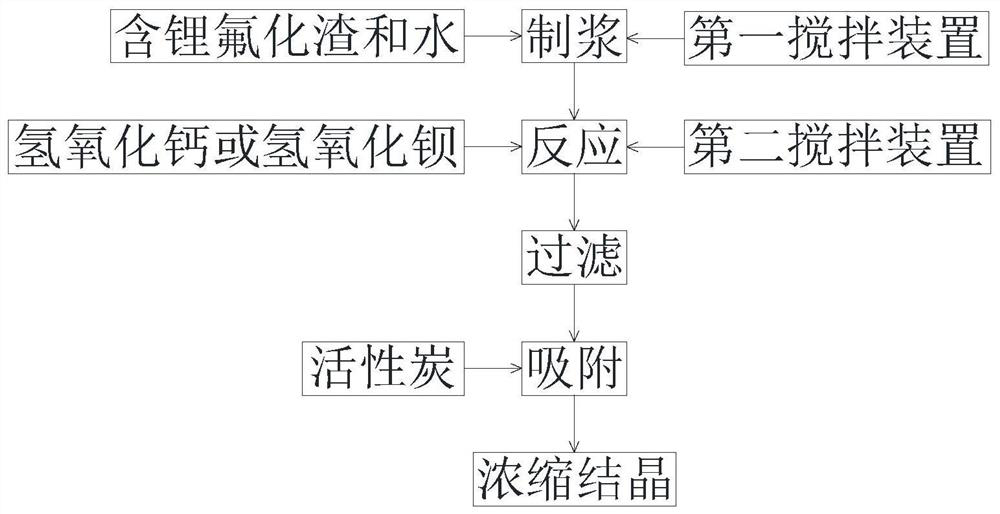

Image

Examples

Embodiment 1

[0027] Step 1, mixing the lithium-containing fluoride slag with a lithium content of 10%wt and water to make slurry, the ratio of solid to liquid is 1:12, and stirring by the first stirring device;

[0028] Step 2: Add the prepared slurry into the reactor, and insert barium hydroxide or calcium hydroxide into the reactor, the ratio of barium hydroxide or calcium hydroxide to lithium-containing fluoride slag is 1.5:10, and Stir by the second stirring device, the rotation speed of the second stirring device is 30r / s;

[0029] Step 3, filtering the reacted solution, filtering to obtain lithium hydroxide solution and filter residue, adding an alkaline reagent to the lithium hydroxide solution, and adjusting the pH of the lithium hydroxide solution to 11;

[0030] Step 4, add 60 purpose gacs to the lithium hydroxide solution, absorb the organic matter in the lithium hydroxide solution;

[0031] Step 5: Concentrate and crystallize the adsorbed lithium hydroxide solution three times...

Embodiment 2

[0033] Step 1, mixing the lithium-containing fluoride slag with a lithium content of 20%wt and water to make slurry, the ratio of solid to liquid is 1:18, and stirring by the first stirring device;

[0034] Step 2, add the prepared slurry into the reactor, and insert barium hydroxide or calcium hydroxide into the reactor, the ratio of barium hydroxide or calcium hydroxide to lithium-containing fluoride slag is 1.9:10, and Stirring by the second stirring device, the rotation speed of the second stirring device is 40r / s;

[0035] Step 3, filtering the reacted solution, filtering to obtain lithium hydroxide solution and filter residue, adding an alkaline reagent to the lithium hydroxide solution, and adjusting the pH of the lithium hydroxide solution to 12;

[0036] Step 4, adding 65 purpose gacs to the lithium hydroxide solution, absorbing the organic matter in the lithium hydroxide solution;

[0037] Step 5, the lithium hydroxide solution after adsorption is concentrated and c...

Embodiment 3

[0039] Step 1, mixing the lithium-containing fluoride slag with a lithium content of 25%wt and water to make slurry, the ratio of solid to liquid is 1:18, and stirring by the first stirring device;

[0040] Step 2: Add the prepared slurry into the reactor, and insert barium hydroxide or calcium hydroxide into the reactor, the ratio of barium hydroxide or calcium hydroxide to lithium-containing fluoride slag is 2.5:10, and Stir by the second stirring device, the rotation speed of the second stirring device is 45r / s;

[0041] Step 3, filtering the reacted solution, filtering to obtain lithium hydroxide solution and filter residue, adding an alkaline reagent to the lithium hydroxide solution, and adjusting the pH of the lithium hydroxide solution to 11;

[0042] Step 4, adding 68 purpose gacs to the lithium hydroxide solution, absorbing the organic matter in the lithium hydroxide solution;

[0043] Step 5: Concentrate and crystallize the adsorbed lithium hydroxide solution three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com