Modified emulsified asphalt preparation process

A technology of emulsified asphalt and preparation process, which is applied in the processing of tar pitch/petroleum pitch/natural pitch, melting processing of tar pitch/petroleum pitch/natural pitch, heating tar pitch/petroleum pitch/natural pitch, etc., which can solve The asphalt block cannot be fully melted, the upper part of the asphalt block cannot be fully melted, and the socket cannot be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

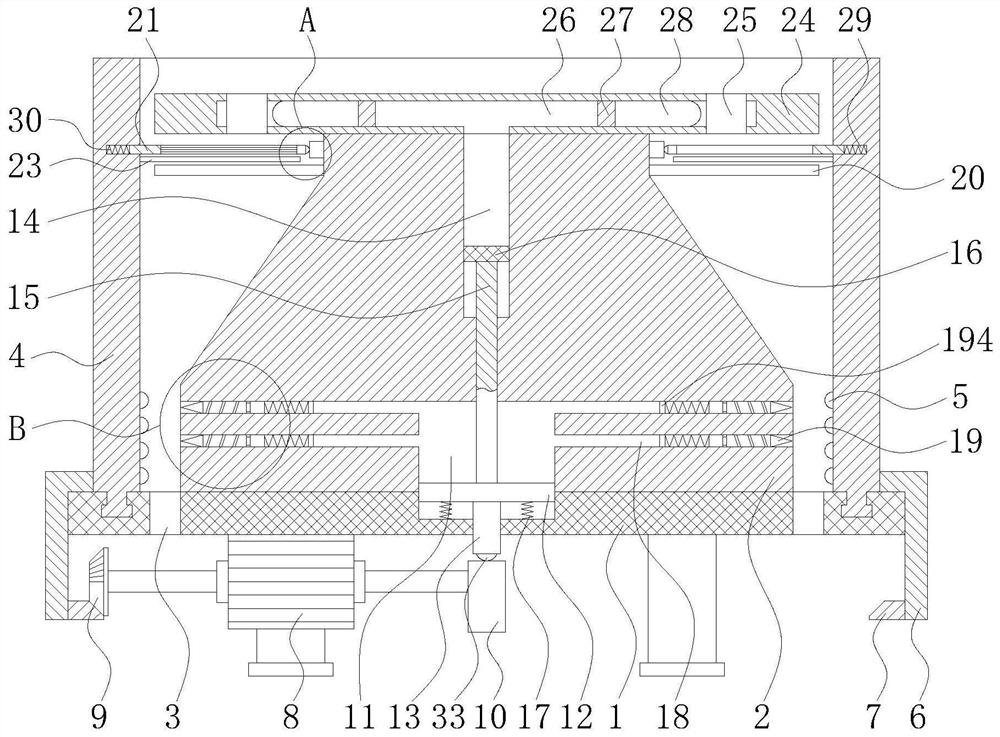

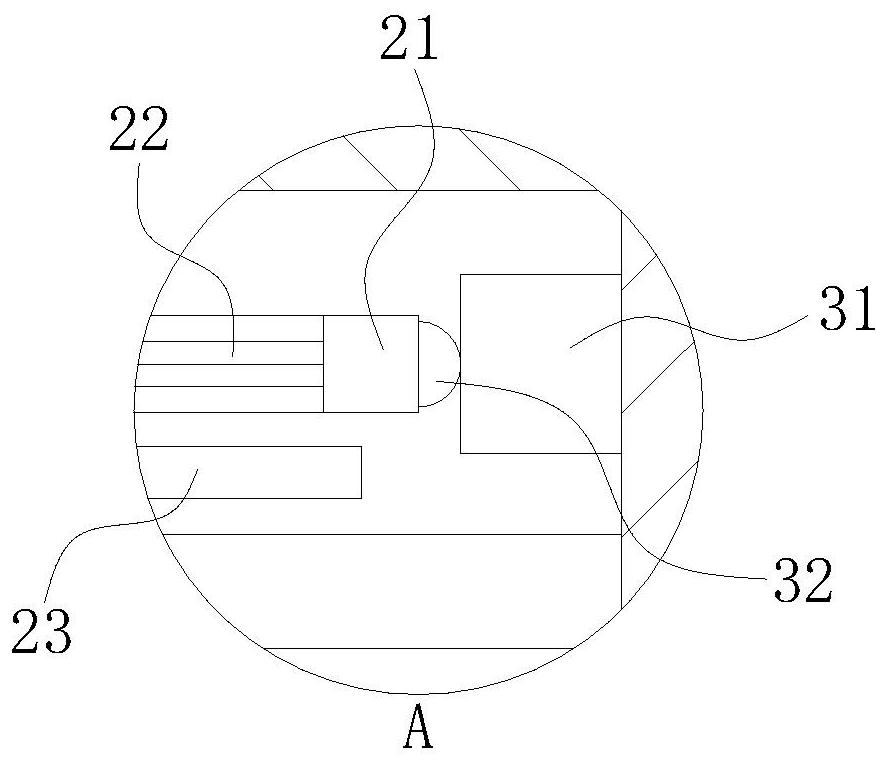

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

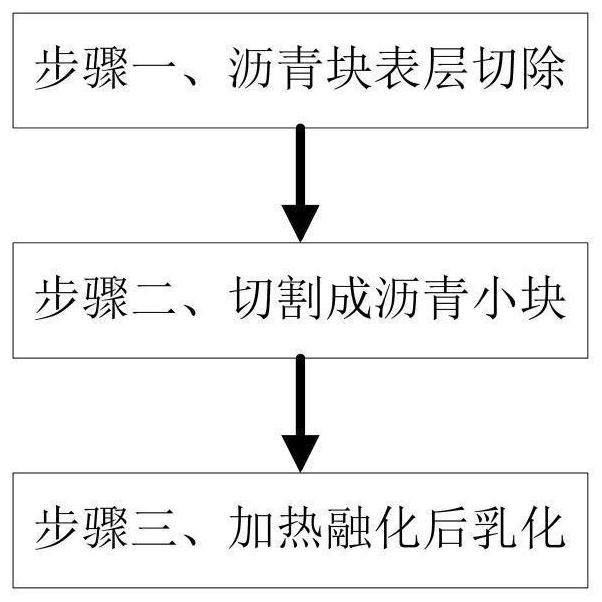

[0033] Such as figure 1 As shown, this embodiment provides a modified emulsified asphalt preparation process, comprising the following steps:

[0034] Step 1. Cut off the surface of the asphalt block: cut off the surface of the cylindrical asphalt block to remove the oxide layer and stains on the surface.

[0035] Step 2: Cutting into small pieces of asphalt: cutting the asphalt block removed from the surface layer into small pieces, and inserting holes on the surface of the small piece of asphalt.

[0036] Step 3, emulsification after heating and melting: heat the cut asphalt pieces into a molten state, and then add emulsifier. Stir the mixture of asphalt and emulsifier evenly to obtain asphalt emulsion. Cool the molten bitumen emulsion to solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com