One-way penetrating agent for digital printing pretreatment of natural fiber fabric

A unidirectional penetration, natural fiber technology, applied in the field of textile printing and dyeing, can solve the problems that affect the printing accuracy of flower patterns, the color difference between the front and back of the fabric pattern, and the turning of silk, etc., so as to improve the printing quality and achieve unidirectional penetration. , Improve the effect of product grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The invention proposes a one-way penetrant for the pretreatment of digital printing of natural fiber fabrics. The one-way penetrant consists of penetrant A, penetrant B and solvent E.

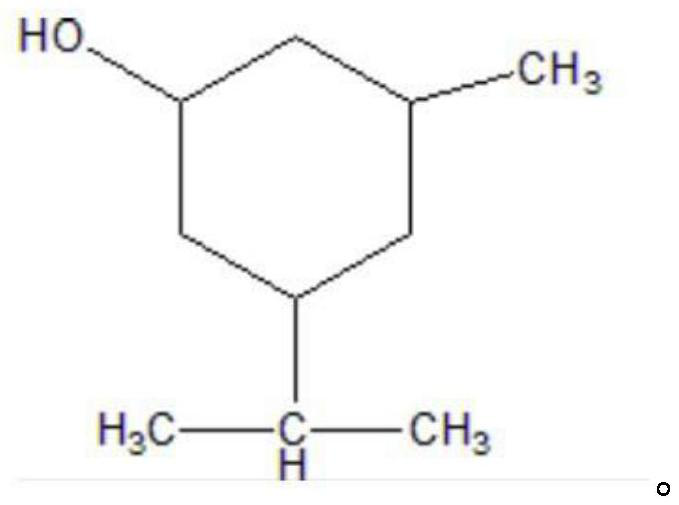

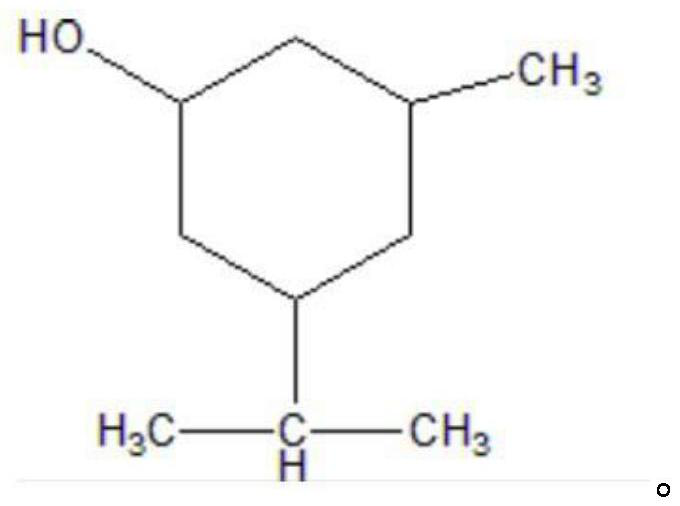

[0025] Wherein, the organic molecular structure of the penetrant A is:

[0026]

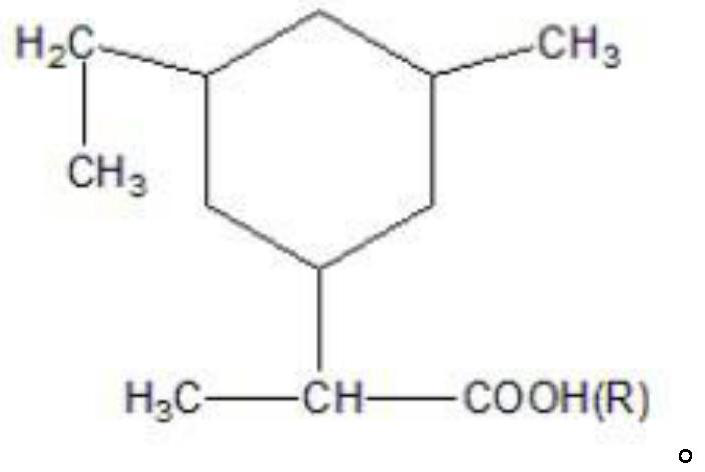

[0027] The organic molecular structure of the penetrant B is:

[0028]

[0029] The solvent E is an aliphatic alkane with an atom number C of 5-8.

[0030] Mix penetrant A and penetrant B at a ratio of 1-9:9-1, dissolve in solvent E that is 2-10 times the dose of penetrant A and penetrant B, and obtain a one-way osmosis that can be used in production agent.

Embodiment 2

[0032] This embodiment is further optimized on the basis of the above-mentioned embodiments, and the same parts as the aforementioned technical solutions will not be repeated here. Further, in order to better realize the present invention, the following setting method is adopted in particular: the one-way penetrating agent It is suitable for the pre-printing treatment of cotton, linen, mulberry silk and other natural fiber fabrics; the one-way penetrant is preferably added to the slurry formula for use in the pre-printing treatment.

[0033] The method of using the one-way penetrating agent in the pretreatment of digital printing of natural fiber fabrics is as follows: use normal temperature to uniformly stir the slurry into a paste according to the set formula on the pulping machine, and initially mix other components of the slurry at a high speed of 2300-2400 (Preferably 2400) rev / min and low speed 1400~1500 (preferably 1500) rev / min alternately make pulp for 25-30 (preferabl...

Embodiment 3

[0035] This embodiment is further optimized on the basis of any of the above-mentioned embodiments, and the same parts as the aforementioned technical solutions will not be repeated here. Further, in order to better realize the present invention, the following setting method is adopted in particular: the one-way The penetrant improves the penetration characteristics of the jet printing ink to the natural fiber fabric by controlling the fabric receiving and limiting the amount and method of jet printing ink immersion, so that the surface of the fabric slurry after sizing and drying has a certain degree of hydrophobicity, which indirectly hinders the hydrophilicity. The active ink diffuses around the surface of the fabric without affecting the natural penetration of the active ink into the interior of the fabric by gravity, thereby improving the dyeing rate of the fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com