Preparation method of metal grid composite electrode

A metal grid, composite electrode technology, applied in metal/alloy conductors, equipment for manufacturing conductive/semiconducting layers, cable/conductor manufacturing, etc. It is difficult to have both rate and conductivity, etc., to achieve the effect of improving light transmittance, good conductivity, and improving conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The present invention provides a kind of technical scheme: a kind of preparation method of metal grid composite electrode, comprises the following steps:

[0028] S1: preparing template coating solution;

[0029] S2: preparing a base template, taking the substrate and the template coating solution in S1, and using the template coating solution to evenly deposit an amine-based thin film on the substrate;

[0030] S3: substrate template processing;

[0031] S4: preparing a metal grid conductive film layer;

[0032] S5: placing the mask plate on the conductive thin film layer, dissolving by laser etching, cleaning and drying to obtain the metal grid conductive thin film layer.

[0033] In this embodiment, uniform deposition of a thin film on the substrate by the template coating solution in S2 specifically includes: immersing the substrate in the template coating solution or spin-coating the template coating solution on the substrate to make the film unifor...

Embodiment 2

[0041] Embodiment 2: a kind of preparation method of metal grid composite electrode, comprises the following steps:

[0042] S1: preparing template coating solution;

[0043] S2: preparing a base template, taking the substrate and the template coating solution in S1, and using the template coating solution to evenly deposit an amine-based thin film on the substrate;

[0044] S3: substrate template processing;

[0045] S4: preparing a metal grid conductive film layer;

[0046] S5: placing the mask plate on the conductive thin film layer, dissolving by laser etching, cleaning and drying to obtain the metal grid conductive thin film layer.

[0047] In this embodiment, uniform deposition of a thin film on the substrate by the template coating solution in S2 specifically includes: immersing the substrate in the template coating solution or spin-coating the template coating solution on the substrate to make the film uniform deposited on the substrate.

[0048] In this embodiment...

Embodiment 3

[0058] Embodiment 3: a kind of preparation method of metal mesh composite electrode, comprises the following steps:

[0059]S1: preparing template coating solution;

[0060] S2: preparing a base template, taking the substrate and the template coating solution in S1, and using the template coating solution to evenly deposit an amine-based thin film on the substrate;

[0061] S3: substrate template processing;

[0062] S4: preparing a metal grid conductive film layer;

[0063] S5: placing the mask plate on the conductive thin film layer, dissolving by laser etching, cleaning and drying to obtain the metal grid conductive thin film layer.

[0064] In this embodiment, uniform deposition of a thin film on the substrate by the template coating solution in S2 specifically includes: immersing the substrate in the template coating solution or spin-coating the template coating solution on the substrate to make the film uniform deposited on the substrate.

[0065] In this embodiment,...

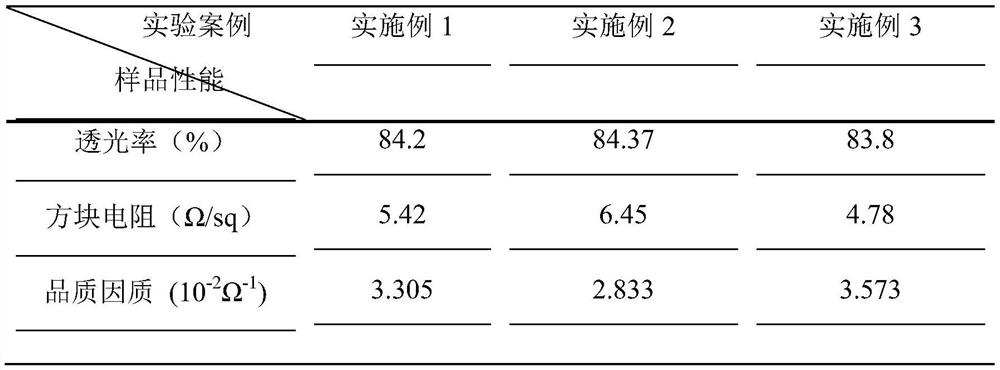

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com