A coupled resonance surface acoustic wave microfluidic chip and manufacturing method thereof

A microfluidic chip, surface acoustic wave technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problem of piezoelectric substrate fragmentation, piezoelectric substrate heating, damage to microfluidic cavity particles Or cells and other problems, to achieve the effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

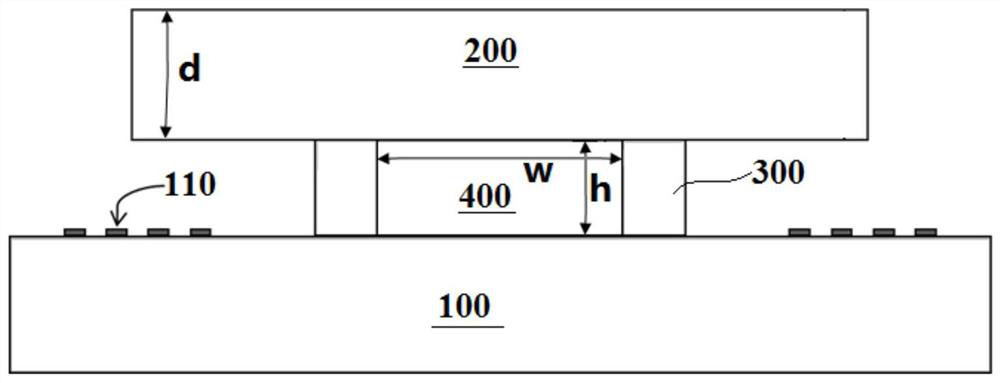

[0040] Such as figure 1 As shown, a coupled resonant surface acoustic wave microfluidic chip of the present invention includes a piezoelectric substrate 100, a cavity top cover 200 and a side wall 300, and a side wall is provided between the piezoelectric substrate 100 and the cavity top cover 200. The wall 300 , and the piezoelectric substrate 100 , the cavity top cover 200 and the side wall 300 enclose the fluid cavity 400 . It is worth noting that the longitudinal section of the piezoelectric substrate 100 of the present invention is rectangular, specifically, the piezoelectric substrate 100 is a thin plate with uniform thickness, and the piezoelectric substrate 100 is made of a flat piezoelectric material or has piezoelectric substrates attached to its surface. An ordinary solid flat plate with electrocoating, the piezoelectric substrate 100 in this embodiment is a glass plate with a zinc oxide piezoelectric thin layer grown on the surface.

[0041] It is worth further ex...

Embodiment 2

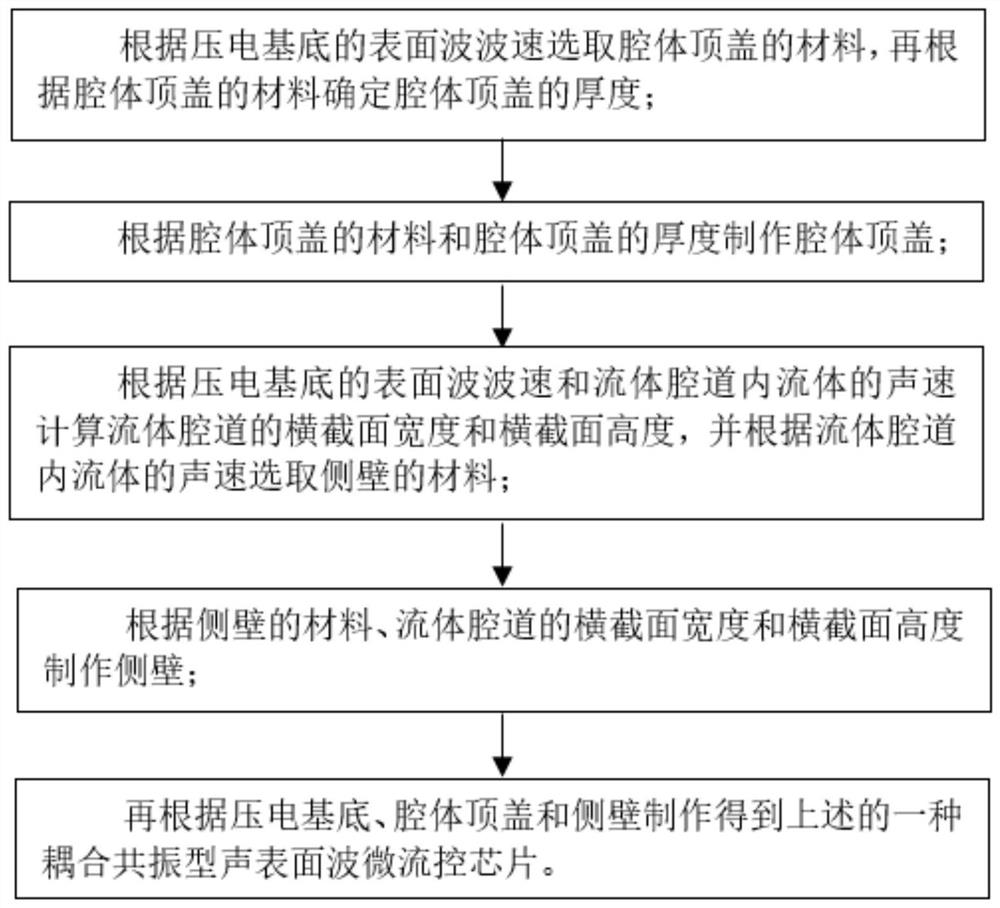

[0064] The content of this embodiment is basically the same as that of Embodiment 1. Specifically, in this embodiment, 128°Y-X lithium niobate is used as the piezoelectric substrate 100, SU-8 photoresist is used as the side wall 300, and Pyrex glass is used as the cavity top. The material of the cover 200 is water as the fluid filled in the fluid channel 400 . The specific steps of the manufacturing method of the coupled resonance surface acoustic wave microfluidic chip in this embodiment are as follows:

[0065] 1) Make cavity top cover 200

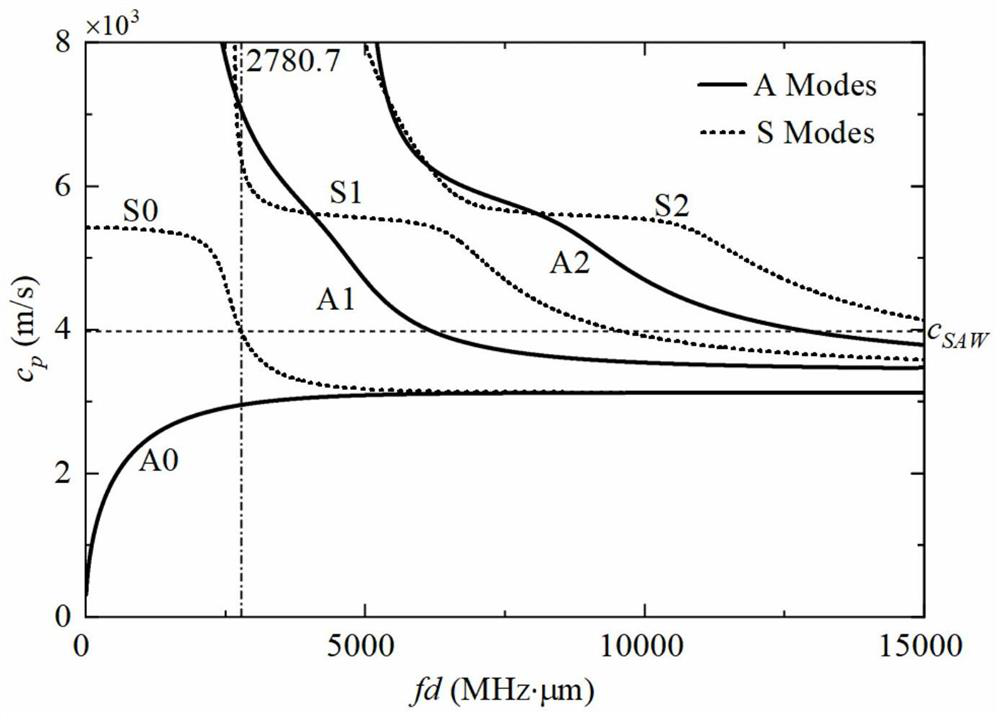

[0066] The surface wave velocity of 128°Y-X lithium niobate is c SAW =3980m / s, the present embodiment selects Pyrex glass as the cavity top cover 200 material, and its shear wave velocity is c T =3424m / s, less than c SAW =3980m / s, so it meets the requirements;

[0067] Then according to the shear wave velocity c of the Pyrex material T and longitudinal wave velocity c L =5592m / s, calculate the phase velocity dispersion curve of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com