Rotary UV curing mechanism

A rotary, fixed plate technology, used in household components, cable/conductor manufacturing, applications, etc., can solve the problems of affecting curing uniformity, long curing time, uneven lighting, etc., to improve product yield and improve curing. Efficiency, the effect of improving the utilization rate of light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

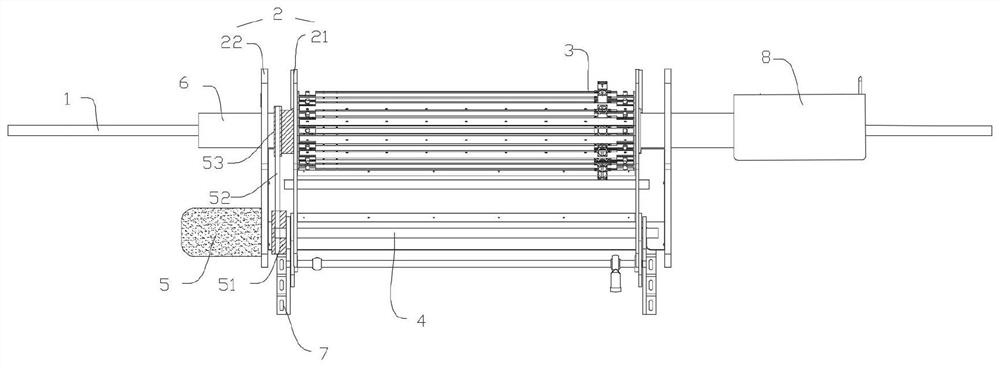

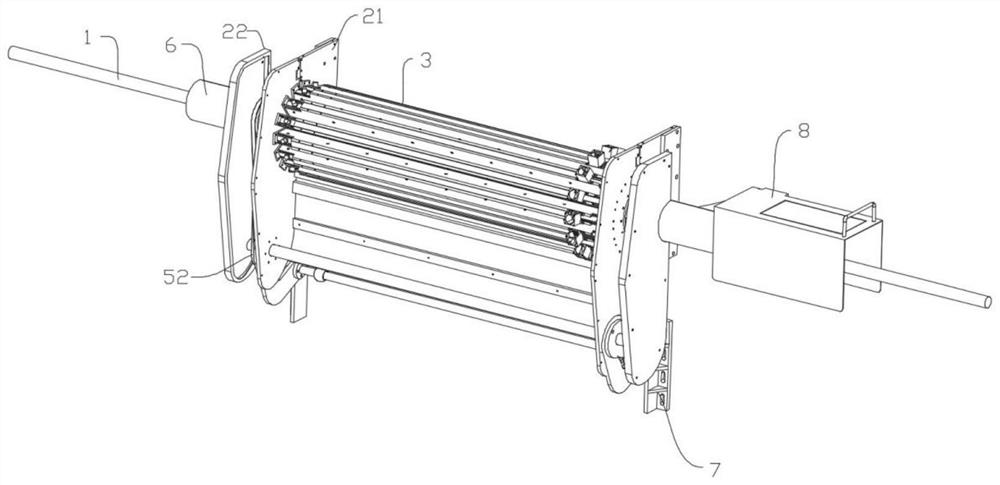

[0017] refer to Figure 1-3 , a rotary UV curing mechanism, comprising: a fixed side plate 2, a curing channel 6, a plurality of lamp holders 3, a driving motor 5 and a length measuring device 8;

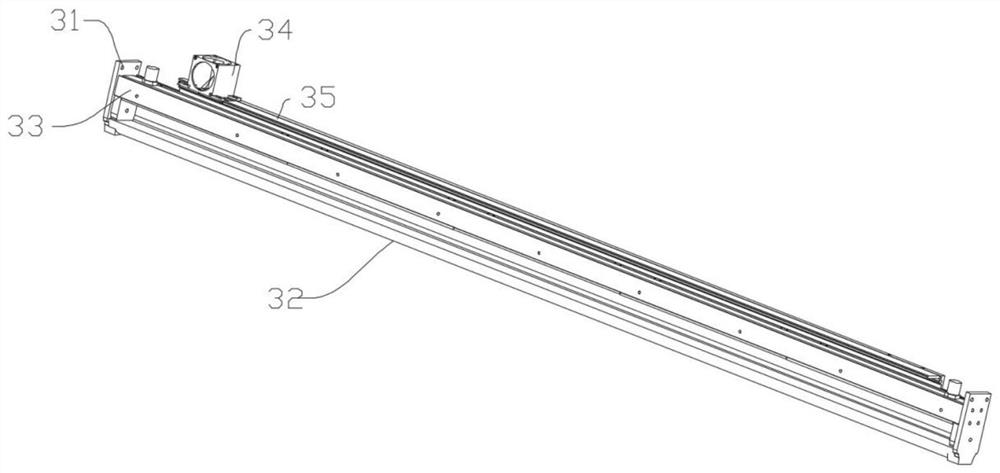

[0018] The fixed side plate 2 includes an outer fixed plate 22 and an inner fixed plate 21, and the plurality of lamp caps 3 are fixed in a ring-shaped circumferential distribution with the ultraviolet irradiation end facing inward, and are installed in a group of inner fixed plates 21 in rotation; the curing The channel 6 passes through the outer fixing plate 22 and the inner fixing plate 22 and goes deep into the inside of the lamp ring surrounded by the lamp holder 3; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com