Direct immersion type cooling shaping processing production line of polyformaldehyde bar and processing method of direct immersion type cooling shaping processing production line

A technology of cooling and shaping, polyoxymethylene, applied in the field of plastic processing, to achieve the effect of avoiding abnormal changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

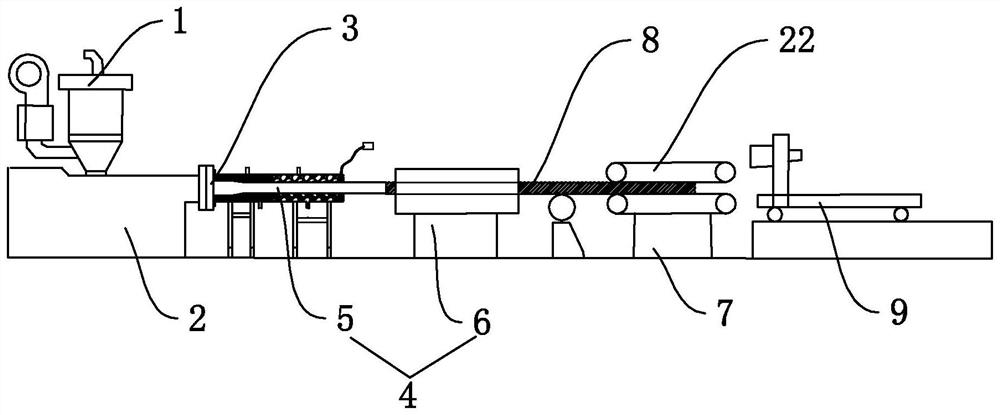

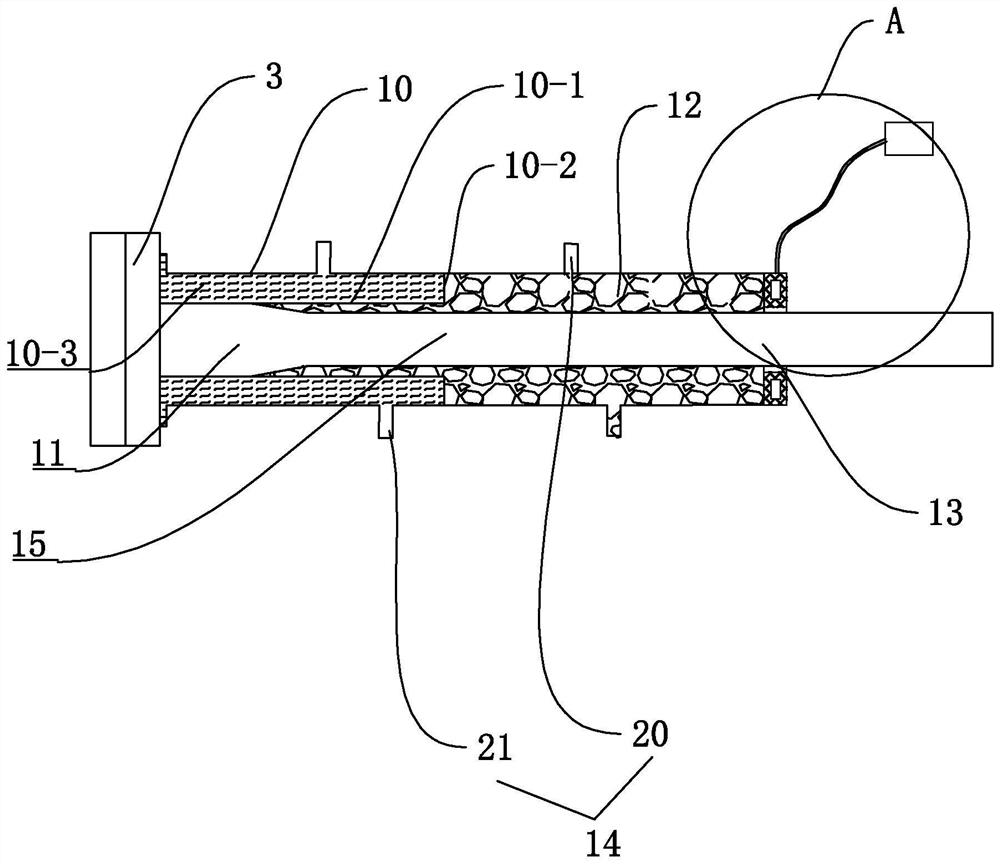

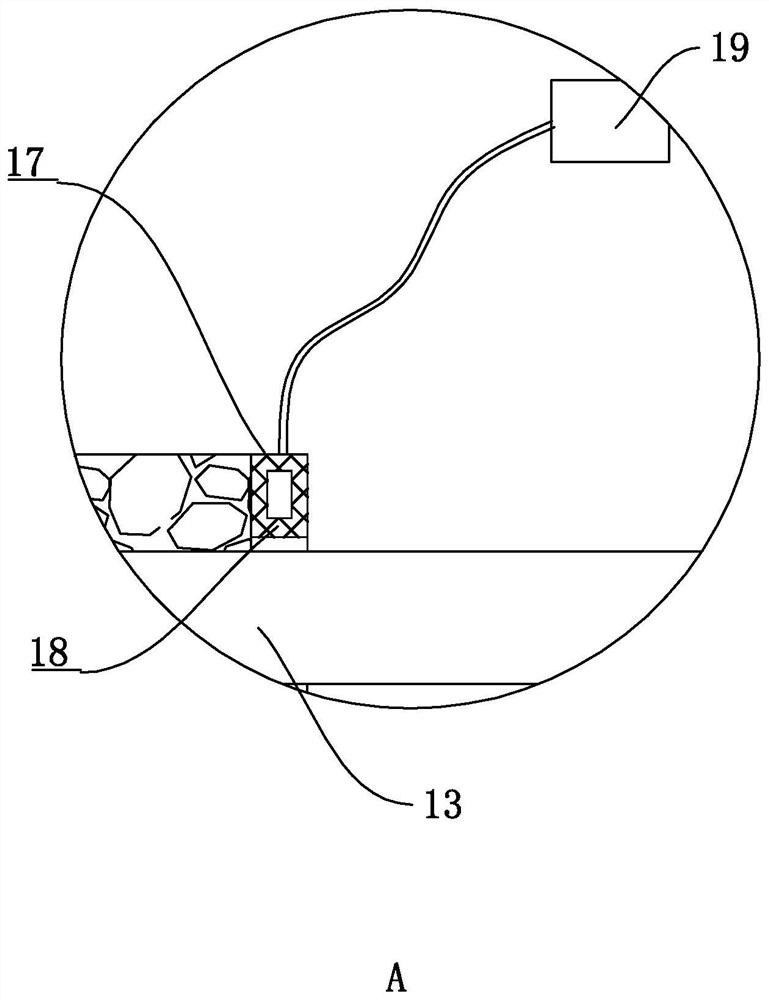

[0045] The following is attached Figure 1-3 The application is described in further detail.

[0046] Embodiment 1 of the present application discloses a direct immersion cooling and shaping production line for polyoxymethylene rods. refer to figure 1, a direct immersion type cooling and shaping production line for polyoxymethylene rods, which sequentially includes a material unloading machine 1, a material extruder 2, a cooling station 4, a pulling station 7 and a cutting station 9. After the raw materials are first put into the material feeder 1, the stirred raw materials are extruded through the extruder head 3 of the material extruder 2 to form a plastic rod. At the first time of extrusion, the plastic rod body is solidified and cooled through the cooling calibrating sleeve 5 in the cooling station 4, and the cooling water tank 6 is used for overall cooling, and finally cut into finished products of required length after passing through the cutting station 9, and pulled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com