High-gloss water-based paint and preparation method thereof

A high-gloss, water-based paint technology, applied in the coating and other directions, can solve the problems of low volatile organic matter content, paint film swelling, prickly heat, etc., to reduce the density and viscosity, high hardening speed, avoid The effect of prickly heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

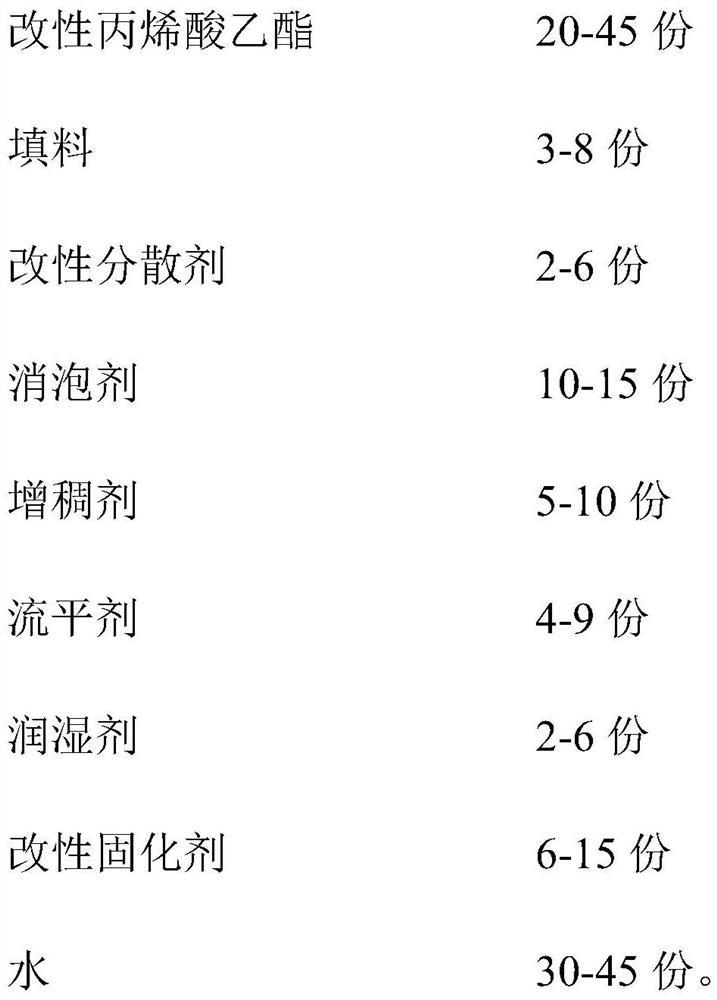

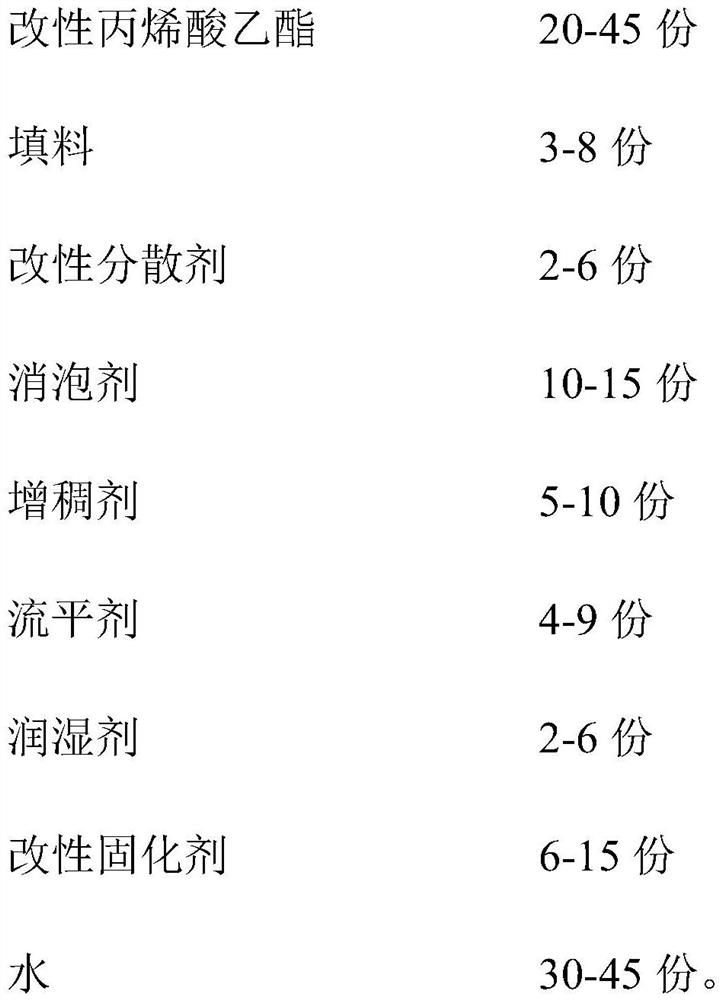

Method used

Image

Examples

Embodiment 1

[0029] Preparation of modified ethyl acrylate:

[0030] Weigh 10 parts of polyvinyl alcohol and 5 parts of ethyl methacrylate, mix and stir evenly, then weigh 10 parts of water and 2 parts of nitric acid, mix them evenly, add them to ethyl methacrylate at 30°C, keep stirring until Dissolve ethyl acrylate, heat and stir for 10 minutes, then weigh 1 part of cerium ammonium nitrate and put it into the mixed solution, heat it for 30 minutes, then add 5 parts of p-phenol, stir well, then add 30 parts of acetone, stir to dissolve, filter, remove The filtrate was obtained to obtain modified ethyl acrylate, which was kept for later use after drying.

[0031] Preparation of modified dispersant:

[0032] Weigh 10 parts of γ-alumina fibers and 20 parts of KH550 silane coupling agent, mix them and perform ultrasonic treatment in an ultrasonic device for 10 minutes, filter and dry to obtain a modified dispersant.

[0033] Preparation of modified curing agent:

[0034] Weigh 2 parts of s...

Embodiment 2

[0041] Preparation of modified ethyl acrylate:

[0042] Weigh 11 parts of polyvinyl alcohol and 6 parts of ethyl methacrylate, mix and stir evenly, then weigh 11 parts of water and 3 parts of nitric acid, mix them evenly, add them to ethyl methacrylate at 35 ° C, keep stirring until Dissolve ethyl acrylate, heat and stir for 10 minutes, then weigh 2 parts of cerium ammonium nitrate and put it into the mixed solution, heat it for 30 minutes, then add 6 parts of p-phenol, stir well, then add 35 parts of acetone, stir to dissolve, filter, remove The filtrate was obtained to obtain modified ethyl acrylate, which was kept for later use after drying.

[0043] Preparation of modified dispersant:

[0044] Weigh 12 parts of γ-alumina fibers and 25 parts of KH550 silane coupling agent, mix them and perform ultrasonic treatment in an ultrasonic device for 15 minutes, filter and dry to obtain a modified dispersant.

[0045] Preparation of modified curing agent:

[0046] Weigh 4 parts o...

Embodiment 3

[0053] Preparation of modified ethyl acrylate:

[0054] Weigh 12 parts of polyvinyl alcohol and 7 parts of ethyl methacrylate, mix and stir evenly, then weigh 12 parts of water and 4 parts of nitric acid, mix them evenly, add them to ethyl methacrylate at 40 ° C, keep stirring until Dissolve ethyl acrylate, heat and stir for 10 minutes, then weigh 3 parts of cerium ammonium nitrate and put it into the mixed solution, heat it for 30 minutes, then add 7 parts of p-phenol, stir well, then add 40 parts of acetone, stir to dissolve, filter, remove The filtrate was obtained to obtain modified ethyl acrylate, which was kept for later use after drying.

[0055] Preparation of modified dispersant:

[0056] Weigh 14 parts of γ-alumina fibers and 30 parts of KH550 silane coupling agent, mix them and perform ultrasonic treatment in an ultrasonic device for 20 minutes, filter and dry to obtain a modified dispersant.

[0057] Preparation of modified curing agent:

[0058] Weigh 6 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com