A high-strength and low-loss cable conductor material and its preparation method and application

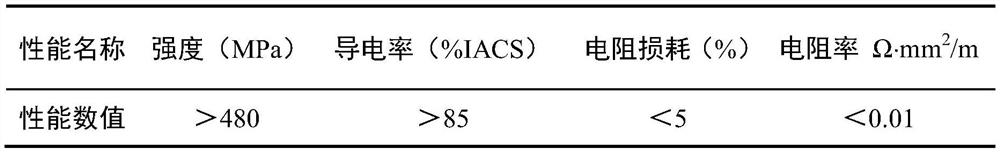

A low-loss cable and conductor material technology, applied in manufacturing tools, metal rolling, heat treatment equipment, etc., can solve the problems of insufficient strength and large loss of power cables, and achieve the effects of enhanced electrical conductivity, increased strength, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

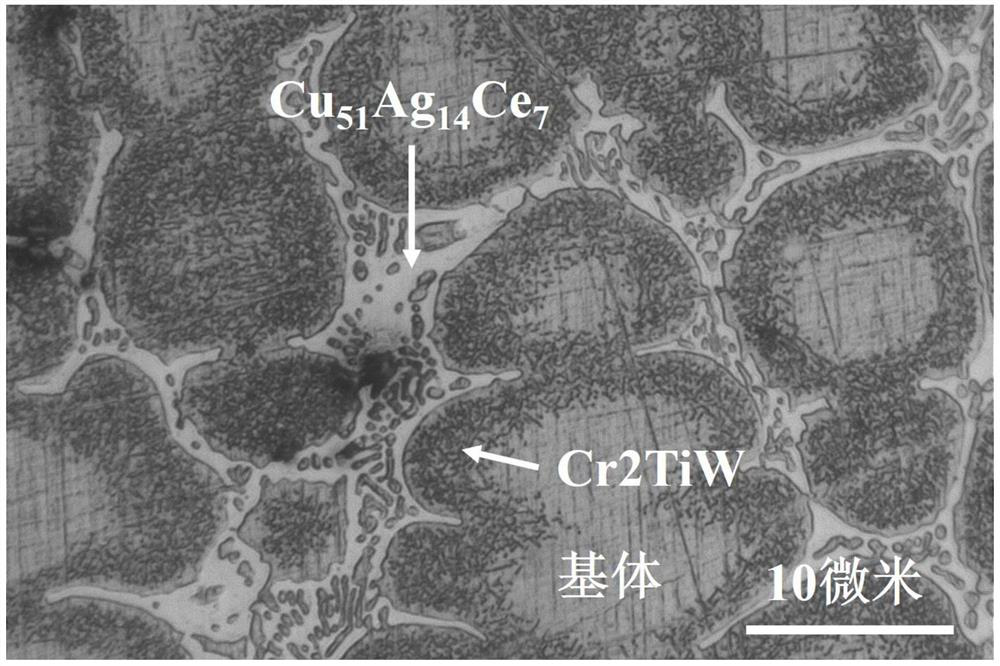

Image

Examples

Embodiment 1

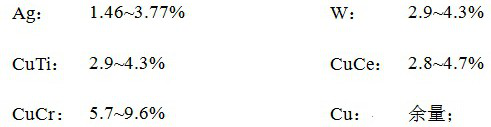

[0033] A high-strength and low-loss cable conductor material includes the following raw materials in terms of mass percentage: Ag: 1.46%; W: 2.9%; CuCe: 2.8%; CuCr: 5.7%; CuTi: 2.9%; Cu: the balance.

[0034] The mass ratio of CuCr, CuTi and W is 2:1:1.

[0035] A method for preparing a high-strength and low-loss cable conductor material, comprising the following steps:

[0036] S1. Alloy smelting: Mix the above raw materials according to the ratio, mix Cu, Ag and CuCe master alloys and heat them to 1580°C for smelting. After they are fully melted, add CuCr, CuTi master alloys and The elemental W is heated up to 1960°C for full melting until it is completely melted to obtain a smelted alloy liquid;

[0037] S2. Continuous casting and rolling: control the casting temperature at 18900°C and the casting speed at 4.1m / min, and cast the S1 smelted alloy liquid into alloy rods; then carry out continuous rolling, rolling by rough rolling and finishing rolling units, and arrange duri...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is only:

[0049] A high-strength and low-loss cable conductor material includes the following raw materials in terms of mass percentage: Ag: 3.77%; W: 4.3%; CuCe: 4.7%; CuCr: 9.6%; CuTi: 4.3%; Cu: the balance.

[0050] A method for preparing a high-strength and low-loss cable conductor material, comprising the following steps:

[0051] S1. Alloy smelting: According to the ratio of raw materials, mix Cu, Ag and CuCe master alloys and heat them to 1620°C for smelting. After they are fully melted, add CuCr, CuTi master alloys and simple substances at a mass ratio of 2:1:1 W, the temperature is raised to 2010°C for full melting until it is completely melted to obtain a smelted alloy liquid;

[0052] S2. Continuous casting and rolling: control the casting temperature at 1920°C and the casting speed at 4.8m / min, and cast the S1 smelted alloy liquid into alloy rods; then carry out continuous rolling, rolling by rough roll...

Embodiment 3

[0060] The difference between this embodiment and embodiment 1 is only:

[0061] A high-strength and low-loss cable conductor material includes the following raw materials in terms of mass percentage: Ag: 2.56%; W: 3.4%; CuCe: 4.5%; CuCr: 6.8%; CuTi: 3.4%; Cu: the balance.

[0062] A method for preparing a high-strength and low-loss cable conductor material, comprising the following steps:

[0063] S1. Alloy smelting: According to the ratio of raw materials, mix Cu, Ag and CuCe master alloys and heat them to 1600°C for smelting. After they are fully melted, add CuCr, CuTi master alloys and simple substances in a mass ratio of 2:1:1 W, the temperature is raised to 2000°C for full melting until it is completely melted to obtain a smelted alloy liquid;

[0064] S2. Continuous casting and rolling: control the casting temperature at 1900°C and the casting speed at 4.5m / min, and cast the S1 smelted alloy liquid into alloy rods; then carry out continuous rolling, rolling by rough ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com