Method for removing dressing at tab part of pole piece for experiment

An experimental, pole piece technology, applied in the preparation of test samples, analysis of materials, sampling, etc., can solve the problems of small number of material samples, inability to adjust size, virtual welding, etc., to achieve a simple removal method, increase the number of use, Ingenious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

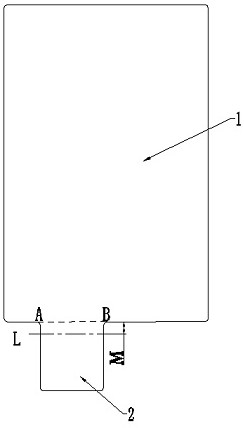

[0033] Embodiment 1: as figure 1 As shown, a method for removing the dressing on the ear of the pole piece for experiments, the method specifically includes the following steps: a preparation operation step, a material removal operation step, and a post-processing operation step;

[0034] The preparatory steps include the following steps:

[0035] 1) Preparation of the operating table: Prepare a clean glass operating table and wipe it clean with a rag; ensure that the operating table is clean and tidy.

[0036] 2) Preparation of auxiliary materials: auxiliary materials include industrial alcohol, plastic hard board, toilet paper, rags, jersey gloves; the size of the plastic hard board is 10cm in length, 5cm in width, and 0.2cm in thickness, and place the auxiliary materials spare.

[0037] 3) Electrode preparation: Select positive and negative electrodes with dressings on the tabs from the electrode material samples.

[0038] 4) Container preparation: the container is made ...

Embodiment 2

[0053] Embodiment 2: as figure 1 As shown, a method for removing the dressing on the ear of the pole piece for experiments, the method specifically includes the following steps: a preparation operation step, a material removal operation step, and a post-processing operation step;

[0054] The preparatory steps include the following steps:

[0055] 1) Preparation of the operating table: Prepare a clean glass operating table and wipe it clean with a rag; ensure that the operating table is clean and tidy.

[0056] 2) Preparation of auxiliary materials: auxiliary materials include industrial alcohol, plastic hard board, toilet paper, rags, jersey gloves; the size of the plastic hard board is 10cm in length, 5cm in width, and 0.2cm in thickness, and place the auxiliary materials spare.

[0057] 3) Electrode preparation: Select positive and negative electrodes with dressings on the tabs from the electrode material samples.

[0058]4) Container preparation: the container is made o...

Embodiment 3

[0073] Embodiment 3: as figure 1 As shown, a method for removing the dressing on the ear of the pole piece for experiments, the method specifically includes the following steps: a preparation operation step, a material removal operation step, and a post-processing operation step;

[0074] The preparatory steps include the following steps:

[0075] 1) Preparation of the operating table: Prepare a clean glass operating table and wipe it clean with a rag; ensure that the operating table is clean and tidy.

[0076] 2) Preparation of auxiliary materials: auxiliary materials include industrial alcohol, plastic hard board, toilet paper, rags, jersey gloves; the size of the plastic hard board is 10cm in length, 5cm in width, and 0.2cm in thickness, and place the auxiliary materials spare.

[0077] 3) Electrode preparation: Select positive and negative electrodes with dressings on the tabs from the electrode material samples.

[0078] 4) Container preparation: the container is made ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com