Machine tool production abnormity alarm remote monitoring system and method based on NB-IOT

A technology of remote monitoring and abnormal alarm, applied in services, transmission systems, general control systems, etc. based on a specific environment, it can solve the problems of inability of monitoring personnel to analyze abnormal causes, high investment costs, and delay in equipment production, so as to improve safety. performance and reliability, strong anti-interference ability, and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical solution and advantages of the present invention clearer, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

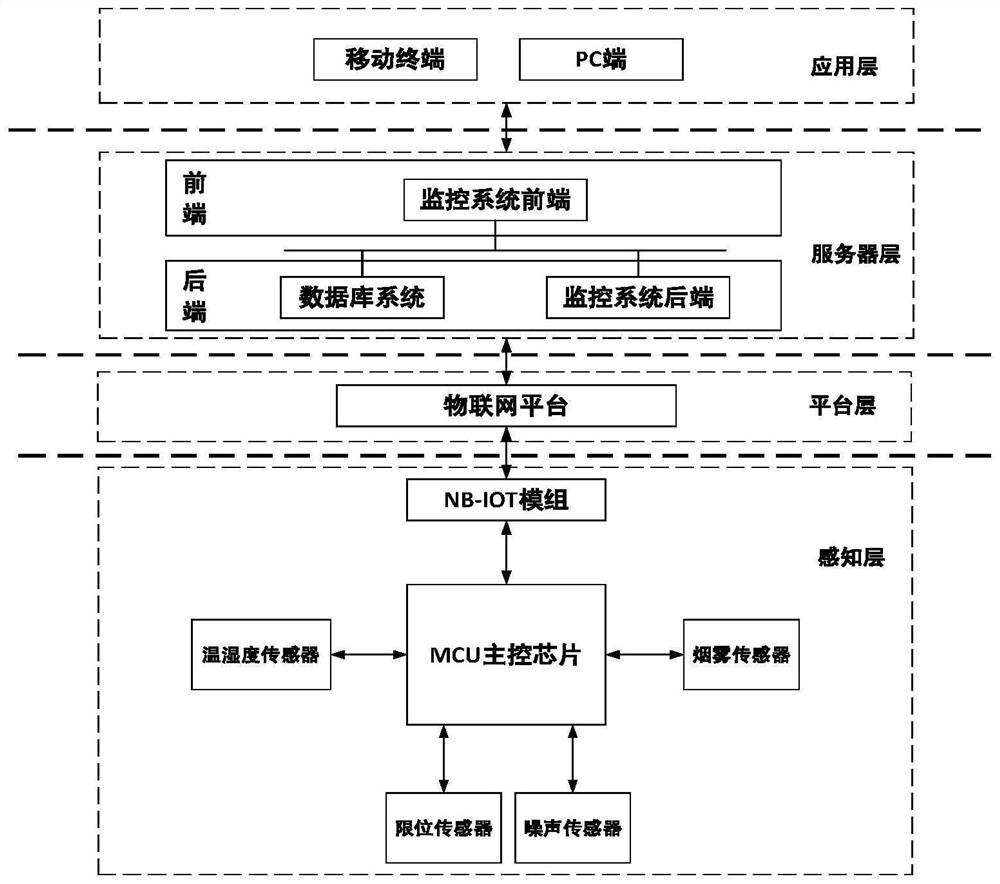

[0041] Such as figure 1 As shown, it is a schematic diagram of the composition of an NB-IOT-based machine tool production abnormal alarm remote monitoring system of the present invention, including a perception layer, a platform layer, a server layer, and an application layer; wherein,

[0042] The perception layer includes temperature and humidity sensors, limit sensors, noise sensors and smoke sensors, MCU main control chip and NB-IOT module; the MCU main control chip is mainly used to control various sensor devices and NB-IOT modules, so that each module coordinates Work; the temperature and humidity sensor, limit sensor, noise sensor, smoke sensor and NB-IOT module are respectively connected to the MCU main control chip through wires; the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com