Bipolar composite electrode plate and preparation method thereof

A composite electrode and bipolar technology, which is applied in the field of lithium-ion batteries, can solve problems affecting battery performance and active materials, and achieve the effects of ensuring battery performance, realizing electronic conduction, and avoiding mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

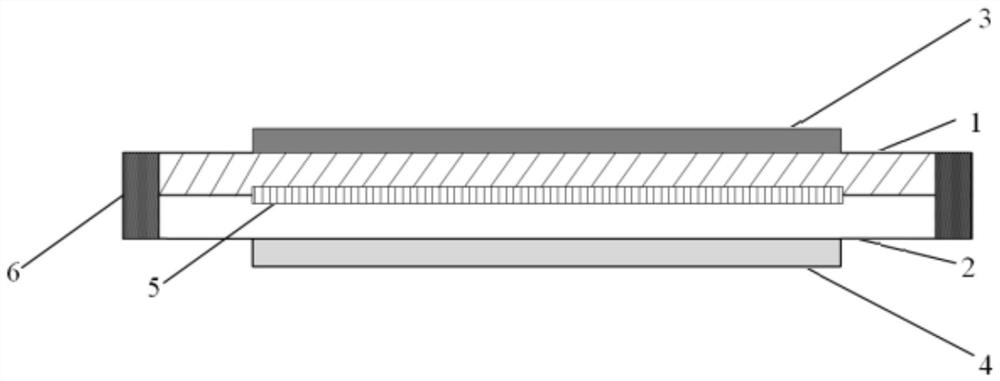

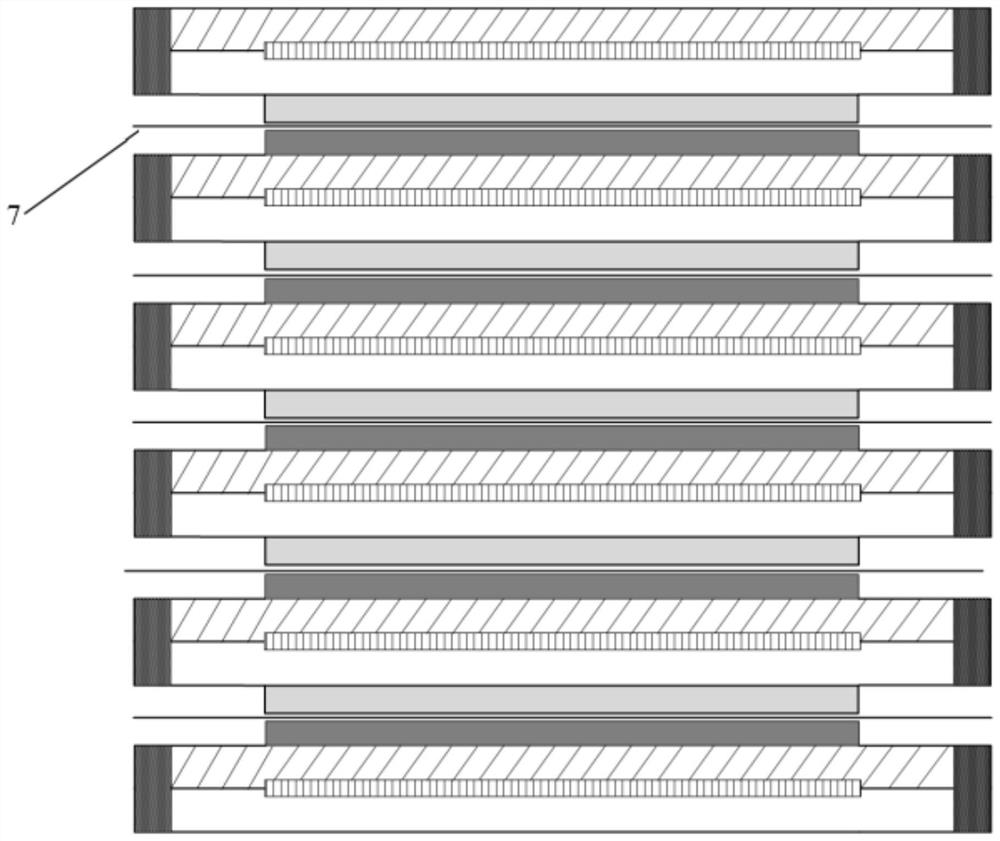

[0022] figure 1 It is a structural schematic diagram of a bipolar composite electrode sheet, including a positive electrode current collector 1 and a negative electrode current collector 2; the central area on one side of the positive electrode current collector 1 is coated with a positive electrode material layer 3, and the central area on one side of the negative electrode current collector 2 is coated with There is a negative electrode material layer 4; the other side of the positive electrode collector 1 and the central area of the other side of the negative electrode collector 2 are connected by a bonding layer 5. The positive electrode current collector and the negative electrode current collector are stacked, and at least one side of the 0.5-5cm blank edge around them is connected by ultrasonic welding or laser welding to form a welding area 6, so as to realize electronic conduction.

[0023] Wherein, the positive electrode collector 1 and the negative electrode colle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com