Metal surface-mounted solid-state relay structure

A solid state relay, metal shell technology, applied in electrical components, electronic switches, pulse technology and other directions, can solve the problems of difficult to achieve automatic welding, complex processing technology, difficult processing, etc., to adapt to automatic production, good temperature adaptability , The effect of good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

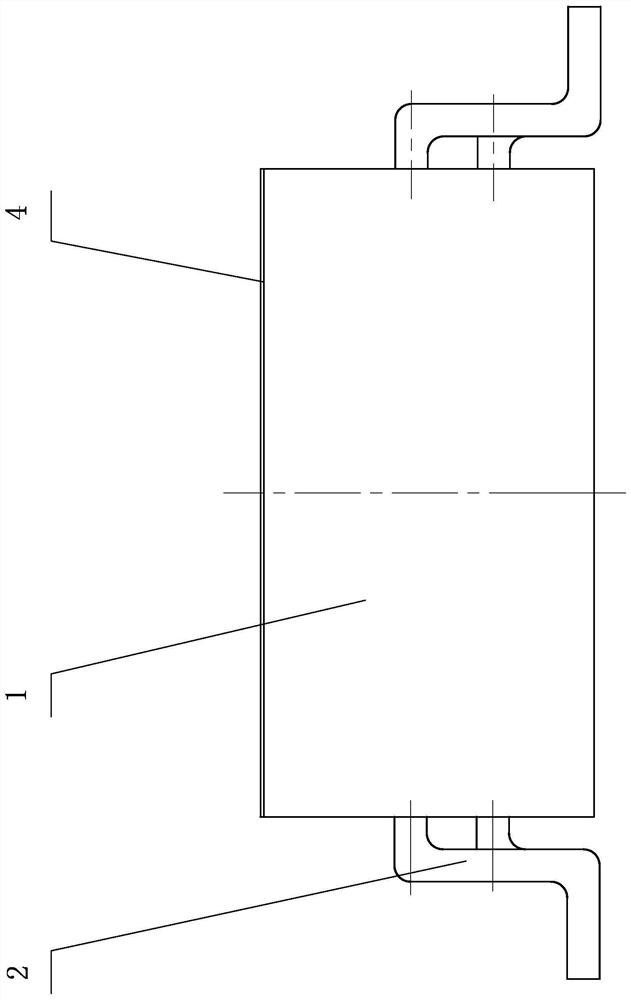

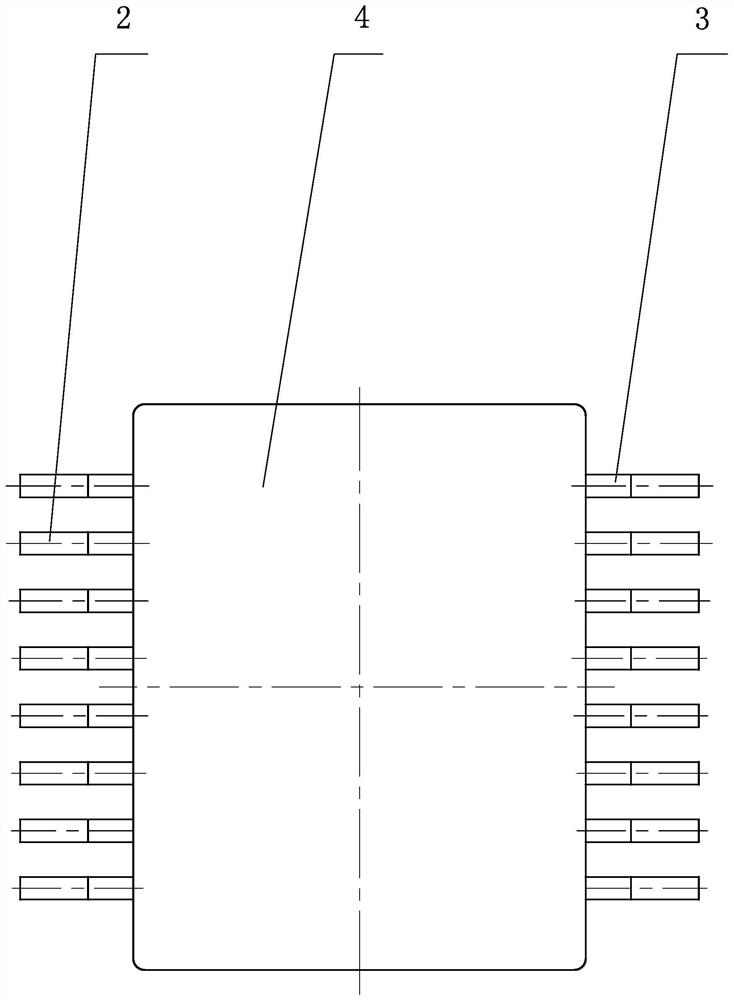

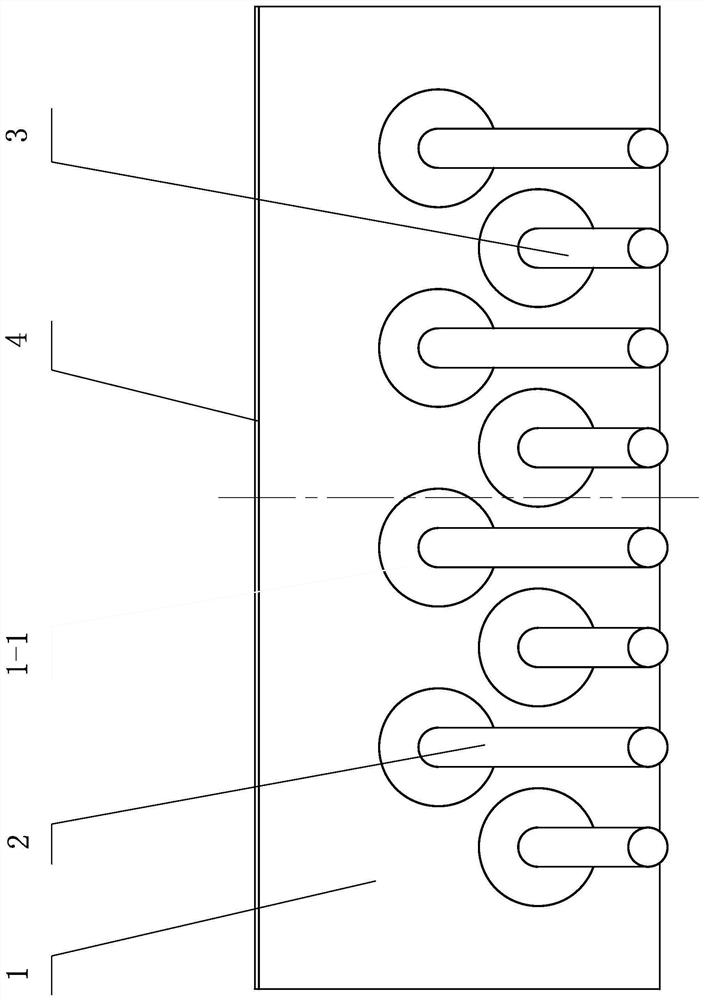

[0027] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0028] The structure of the metal surface-mounted solid state relay of the present invention includes a metal shell part in which the power output part, the connection part and the input driving part are packaged. The source is used to conduct the output end of the solid state relay. The function of the connection part is to carry the input drive part and connect the input drive part and the power output part. The function of the input drive part is to receive the control signal, and the output grid-source is turned on Voltage.

[0029] The metal shell part includes a metal die-cast shell base 1, a thin cover plate 4, and left and right electrode rod groups. The seat is welded as a whole, and the left and right sides of the shell seat 1 are symmetrically provided with eight lead-out holes 1-1 with equal intervals in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com