Preparation method and application of Mg/Ca loaded modified tobacco stalk biochar

A biochar and tobacco stalk technology, applied in chemical instruments and methods, chemical/physical processes, other chemical processes, etc., can solve problems such as the decrease in adsorption capacity, and achieve the effect of high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of Mg / Ca loaded modified tobacco stalk biochar, according to the mass ratio of Mg to tobacco stalk is 0.3:1, 20g of tobacco stalk powder is added to 180mL MgCl 2 Then add 20 g of egg shell powder, stir at room temperature for 1 h, then dry in an oven at 105 °C for 8 h, transfer the mixture into a porcelain crucible, heat up to 700 °C in a muffle furnace at 5 °C / min for 2 h, and wait for After the temperature in the furnace was cooled to room temperature, it was taken out, washed three times with deionized water, vacuum filtered, dried at 105°C for 6 hours, and crushed through a 60-mesh sieve to obtain Mg / Ca-loaded modified tobacco stalk biochar. The biochar was named EM-C24.

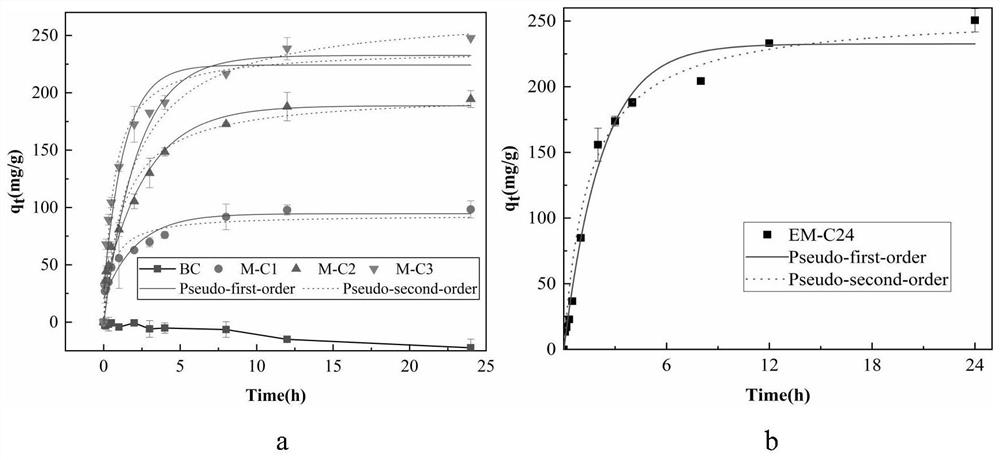

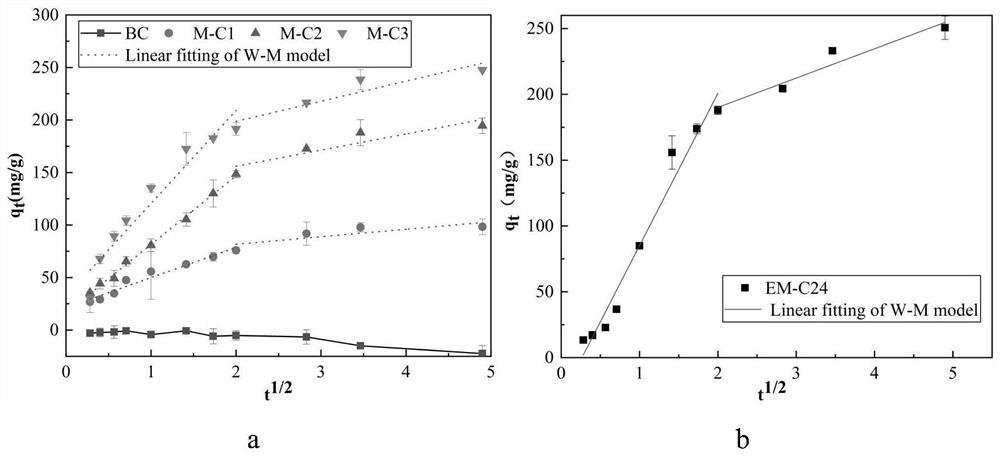

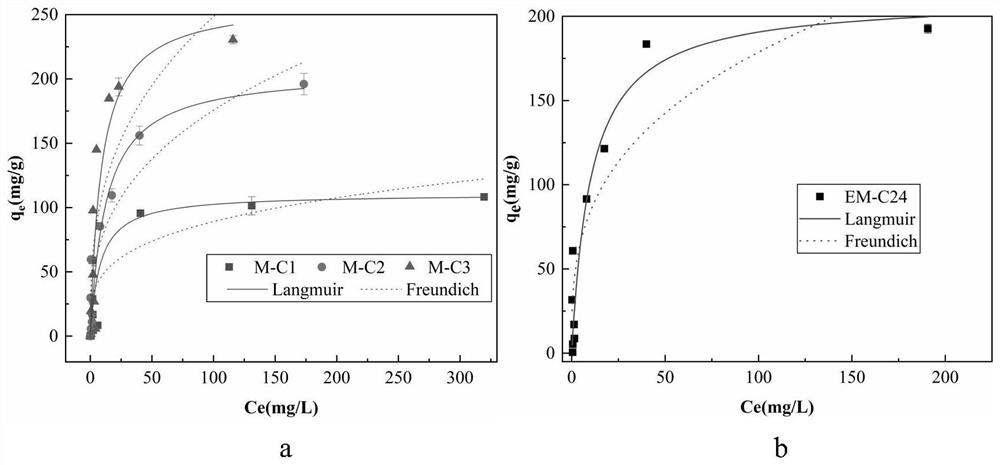

[0027] Study on Kinetics and Isotherms of Phosphate Adsorption

[0028] Configure different concentrations of MgCl 2 Solution, according to the mass ratio of Mg to tobacco stalks is 0:1, 0.12:1, 0.3:1, 0.48:1 respectively, add 20g of tobacco stalk powder to 180mL of MgCl wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com