Stainless steel rod rust removal device based on ice-solid scraping technology and application method

A stainless steel rod and stainless steel technology, applied in the field of stainless steel rod derusting device, can solve the problems of manual grinding trouble, reduce the work efficiency of technicians, etc., and achieve the effect of improving the connection firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

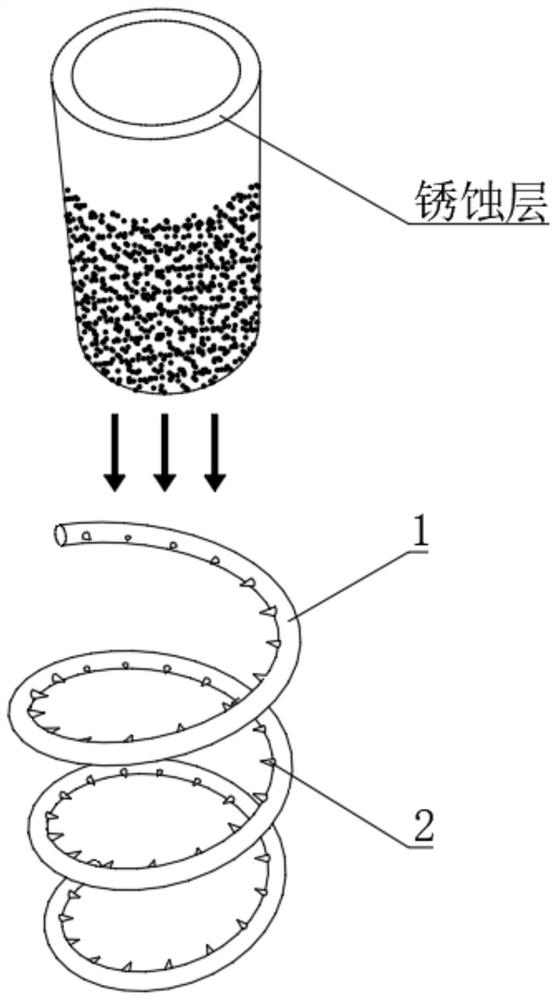

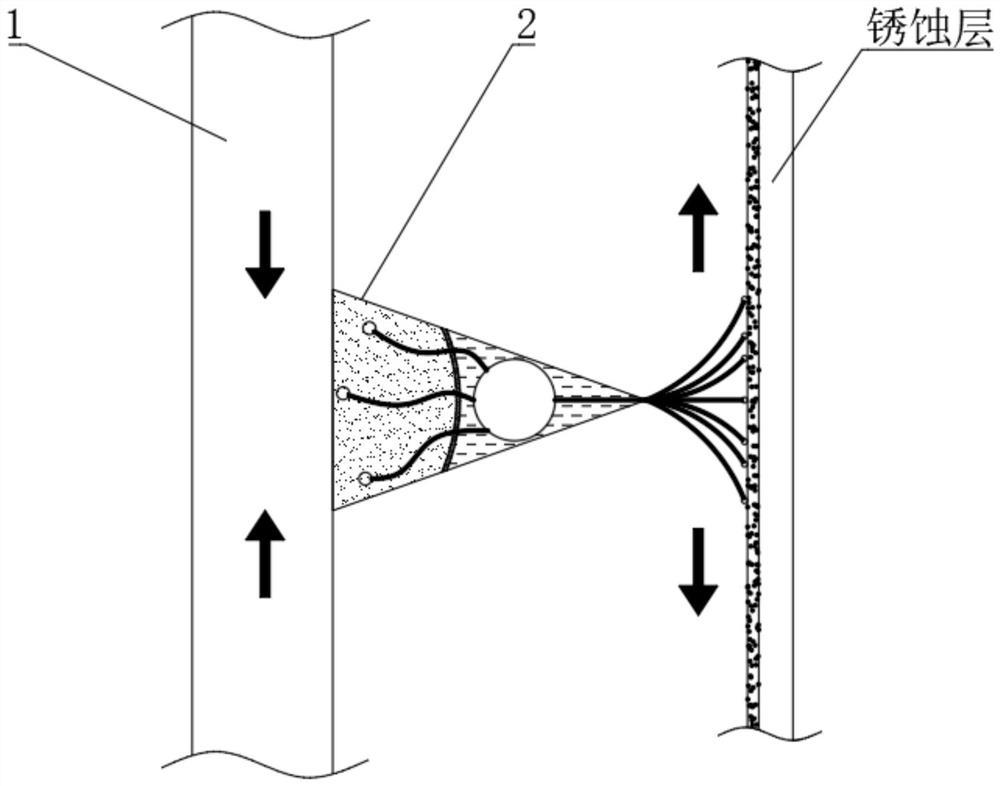

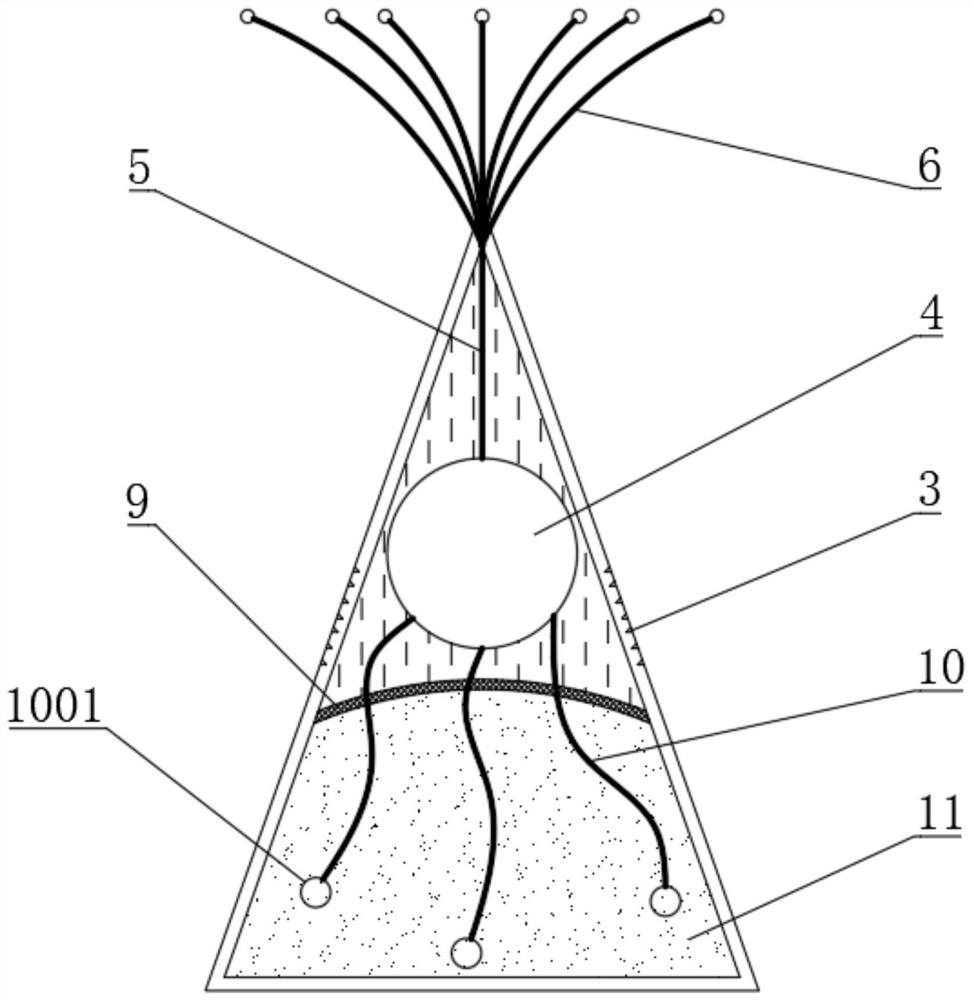

[0040] see Figure 1-5 , a stainless steel rod derusting device based on ice-solid scraping technology, comprising an outer spiral derusting ring 1 arranged on the outside of the stainless steel rod, before the stainless steel rod is derusted, the surface of the stainless steel rod is coated with saltpeter powder and carbonic acid The reaction powder made by mixing calcium hydrogen powder at 1:1, on the one hand, can quickly cool down with the help of saltpeter powder and water and make the outflowing water freeze, thereby forming an ice layer on the surface of the stainless steel rod; Thermal decomposition can promote thermal decomposition and produce calcium carbonate powder and carbon dioxide gas. It can not only blow away the rust stains from scraping, but also improve the efficiency of scraping stainless steel rods with the help of calcium carbonate powder. The outer spiral rust removal ring 1 outer end A plurality of evenly distributed scraping cones 2 are fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com