Household garbage collecting and treating equipment

A technology for processing equipment and domestic waste, applied in the direction of garbage collection, trash cans, household appliances, etc., can solve the problems of large living garbage gap, domestic garbage dumping, environmental pollution, etc., and achieve the effect of reducing space, stable storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

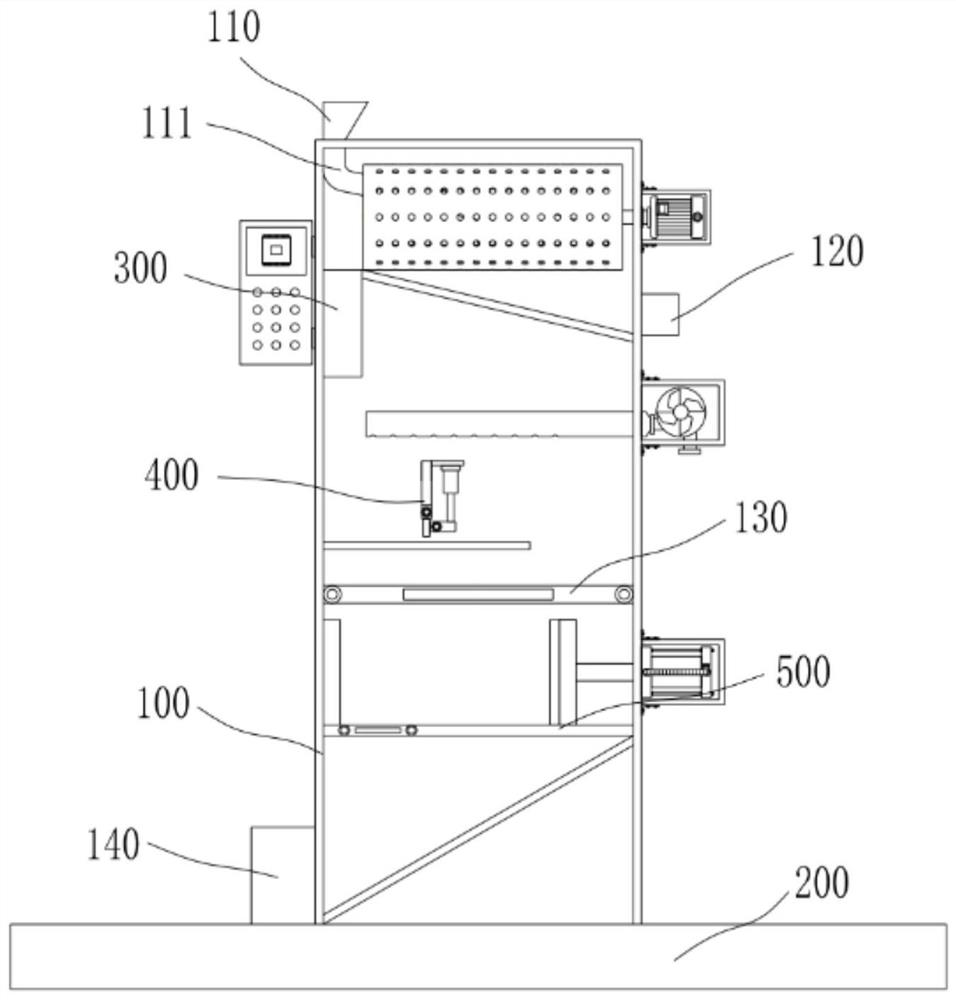

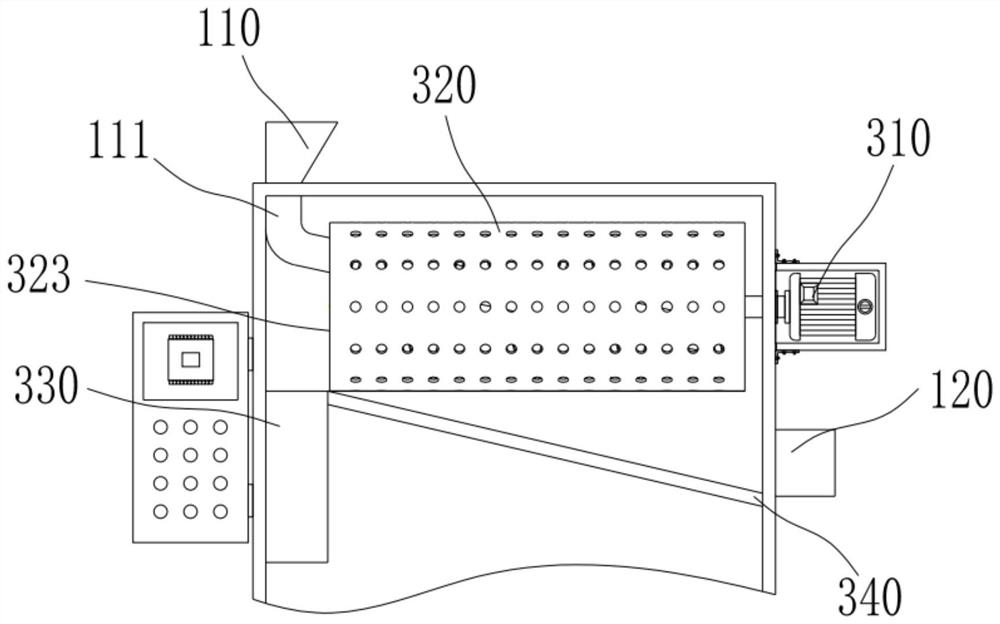

[0038] see Figure 1-14 , the present invention provides a technical solution: a domestic garbage collection and treatment equipment, including a fixed seat 200, the upper end of the fixed seat 200 is provided with a treatment box 100, the upper end of the treatment box 100 is provided with a feed port 110, and the right side of the treatment box 100 is provided with a The water outlet 120, the bottom left side of the treatment box 100 is provided with a discharge port 140; the feed inlet 110 is connected with a feed pipe 111 in the treatment box 100, and the feed pipe 111 is arranged obliquely, and the feed pipe 111 is connected from the first-level discharge port 323 extends to the right side of the drum 320;

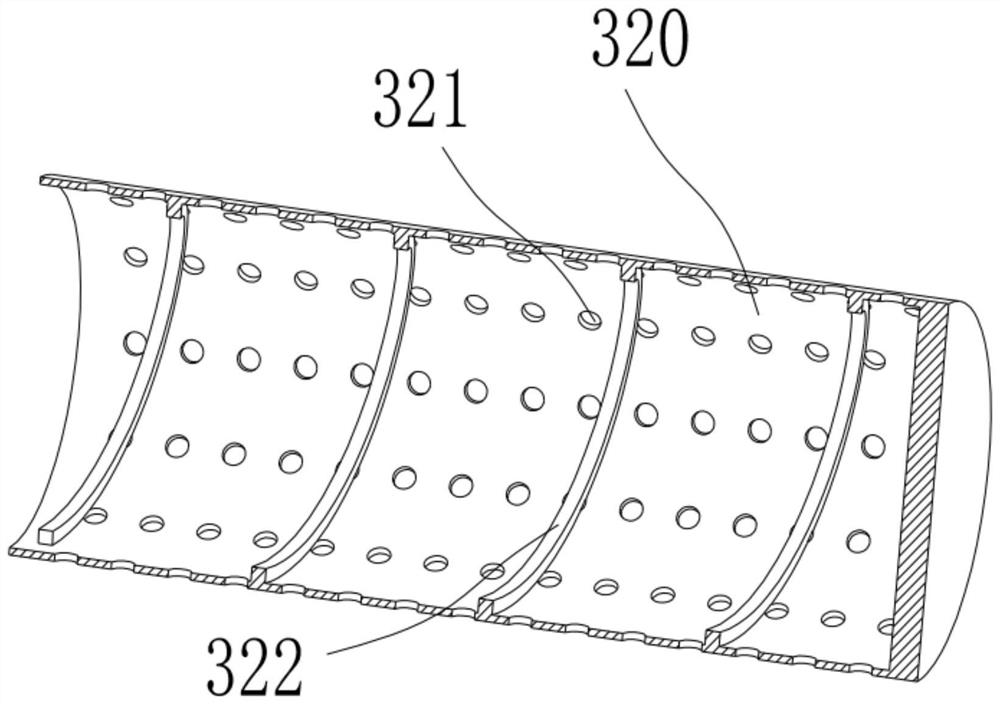

[0039] The water removal mechanism 300, the water removal mechanism 300 comprises the first motor 310 arranged on the outer wall of the right side of the processing box 100 and the cylinder 320 arranged in the treatment box 100, the first motor 310 is driven and conne...

Embodiment 2

[0042] drying mechanism 400, see Figure 1-3 , the drying mechanism 400 includes a drying plate 410 arranged on the bottom of the water removal mechanism 300, a hot air blower 420 arranged on the right side wall of the processing box 100, and a second motor 460 arranged on the outer wall of the front side of the processing box 100, and the drying plate 410 Horizontally installed, the right side of the drying plate 410 is provided with a secondary discharge port 411, and a hot air pipe 430 is provided above the drying plate 410. The hot air pipe 430 is connected to the hot air blower 420, and there are several air outlets on the lower side of the hot air pipe 430. 431, a moving plate 440 is arranged above the drying plate 410, the lower end of the moving plate 440 is hinged with a scraper 450 through the movable assembly 443, the upper end of the moving plate 440 is provided with a mounting plate 441, and the lifting hydraulic cylinder 442 is arranged on the mounting plate 441, ...

Embodiment 3

[0045] Compression mechanism 500, compression mechanism 500 comprises the collecting plate 510 that is arranged on drying mechanism 400 below and the extruding hydraulic cylinder 520 that is arranged on the outer wall on the right side of treatment box 100, and collecting plate 510 is horizontally arranged, and the left side of upper end of collecting plate 510 A baffle plate 530 is provided, and several groove bodies 531 are arranged at intervals on the right side wall of the baffle plate 530, and an extruding plate 540 is arranged on the right side of the upper end of the collecting plate 510, and several grooves 531 are arranged at intervals on the left side wall of the extruding plate 540. The structure of the convex body 541, the groove body 531 and the convex body 541 are matched, the piston rod of the extrusion hydraulic cylinder 520 is connected to the extrusion plate 540 by driving, and the bottom electric control valve 511 is installed on the collecting plate 510 near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com