Preparation method of integrally-formed inductor, and integrally-formed inductor

An inductance and integrated technology, applied in transformer/inductor parts, inductance/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, etc., can solve the problem of inductance drop of integrated inductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

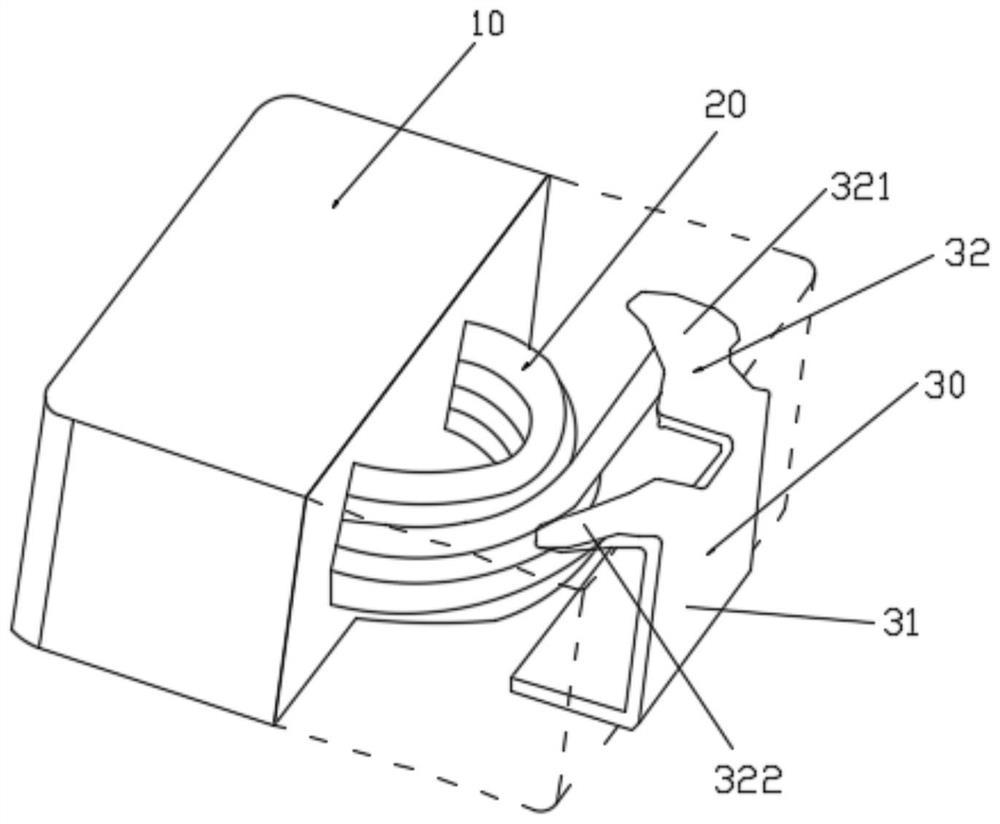

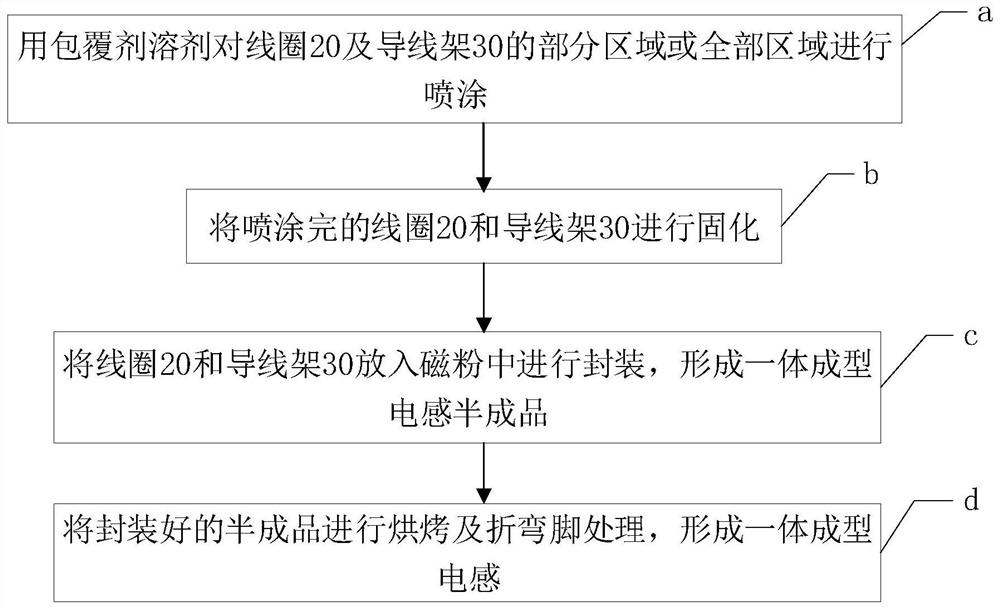

[0037] In order to solve the problem that the enamelled film of the integrally formed inductor is easily punctured during molding, the present invention proposes a method for preparing the integrally formed inductor. figure 2 It is a block flow diagram of the preparation method of integrally formed inductors in the present invention, such as figure 2 Shown, preparation method comprises the steps:

[0038] a. Partial or all areas of the coil 20 and the lead frame 30 are sprayed with a coating agent solvent;

[0039] b. Curing the sprayed coil 20 and the lead frame 30;

[0040] c. Put the coil 20 and the lead frame 30 into the magnetic powder for encapsulation to form an integrated inductor semi-finished product;

[0041] d. Baking the packaged semi-finished product and bending the feet to form an integrated inductor.

[0042] In the present invention, part or all of the coil 20 and the lead frame 30 are sprayed with a coating agent solvent, and then the coil 20 and the lea...

Embodiment 1

[0048] (1) spot welding coil 20 and lead frame 30 are spare, and quantity is 10000pcs (piece), and the coil 20 model used in the present embodiment is DCY1A0854-470-YD60;

[0049] (2) Mix the coating agent and water according to a certain ratio, and use a mixer to stir for 10-40min until uniform;

[0050] (3) Use a spray gun to insulate and coat the coil body, coil leads, solder joints, and lead frame feet 312 to be embedded in the powder. The scope of coating can be flexibly selected according to needs, and the coating objects are not all limited to the locations described above;

[0051] (4) After spraying, place the coil 20 and the lead frame 30 in a nitrogen oven at a temperature of 120°C and bake for 30-60 minutes until the insulating coating agent is cured, then turn off the power supply so that the coil 20 and the lead frame 30 together The furnace can be cooled;

[0052] (5) Finally, the coil 20 obtained in (4) and the lead frame 30 are packaged together into soft ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com