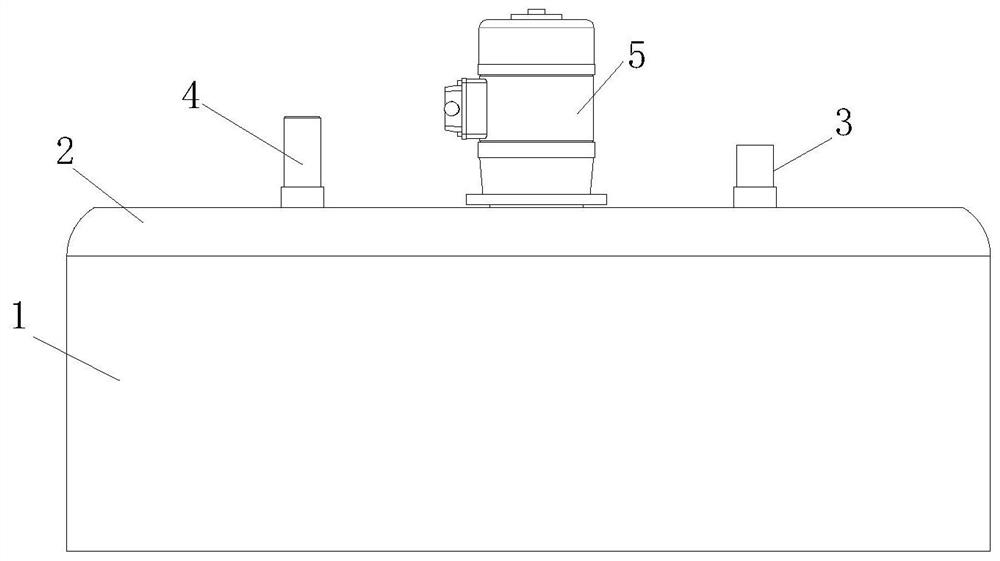

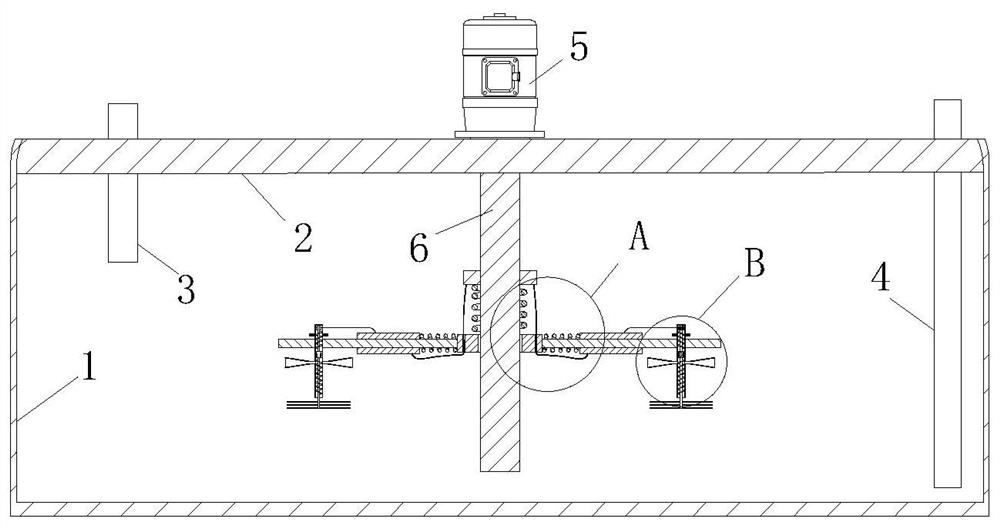

Factory sewage treatment tank

A kind of sewage treatment pool, the technology of treatment pool, applied in the direction of water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. The treatment effect is not ideal enough to achieve the effect of improving the efficiency of oxidation and decomposition, accelerating the exchange and increasing the effect of flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

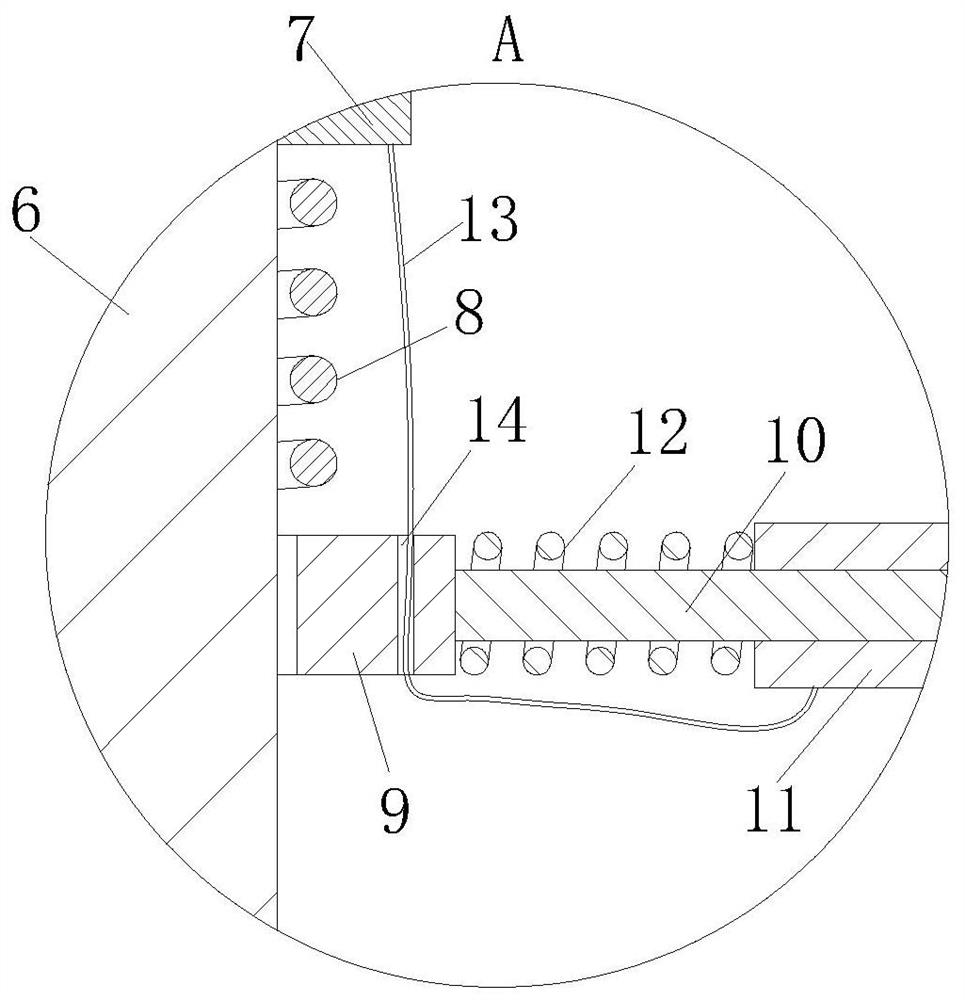

[0030]As an embodiment of the present invention, a one-way valve that conducts one-way downwards is provided on the flow hole 19. Through the setting of the one-way valve, the one-way flow of the flow hole 19 can be realized, which not only realizes the forced mixing of the air above the piston 18 to the bottom of the piston 18 and the sewage, but also prevents the sewage from entering the vertical cylinder 15 above the piston 18 Cause pollution problems.

[0031]When in use, the sewage to be treated is introduced into the treatment tank 1 through the sewage inlet pipe 3, and the motor 5 is started; due to the arrangement of the main stirring rod 10 and the second spring 12, the sliding sleeve 11 can overcome the second spring under the action of centrifugal force The elastic force of 12 moves to the outside, so the position of the sliding sleeve 11 is different when the rotation speed of the first rotating shaft 6 is different, so it can stir the sewage back and forth, increase the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com