Preparation method of cationic liquid dye

A technology of liquid dyes and cations, which is applied in the field of dyes, can solve the problems of high index of acetone insolubles, discounts and restrictions on dyeing performance, and achieve the effects of less increase in process costs, improved application performance, and less cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

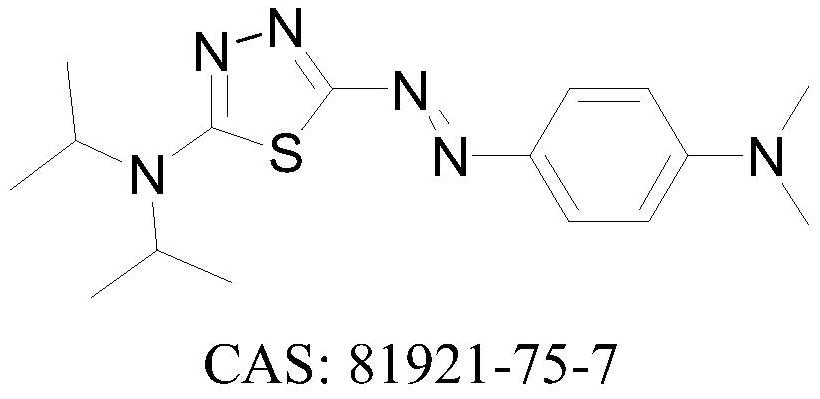

Image

Examples

specific Embodiment

[0029] Specific examples are as follows:

[0030] Add 33g of blue-159 parent dry product and 2.3g of magnesium oxide into a 500ml four-necked reaction flask, then add 50g of water and 100g of acetic acid and stir well. At room temperature (20-25°C), slowly add 33.0 g of dimethyl sulfate dropwise, and control the temperature in the pot at 20-25°C during the process (the dropwise addition is completed in about 1 hour). Control the temperature of the material at 20-25°C and keep stirring for 3 hours; take a sample and analyze the end point of methylation (TLC: n-butanol: acetic acid: water = 4:1:5 or toluene: ethanol = 4:1, as long as the mother spot disappears to the end of the reaction.)

[0031] Extraction is a method of extracting a solute from a solution composed of it and another solvent by using the different solubility of the solute in immiscible solvents.

[0032] The extraction process here is to use the difference in solubility between the target dye molecule in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com