Hollow microbead three-dimensional matrix laminate for heat insulation, sound insulation, self-cleaning, sterilization and air cleaning

A three-dimensional matrix, clean air technology, applied in coatings, devices for applying liquid to surfaces, covering/lining, etc., can solve the problems of lack of beads in the coating process, cumbersome and other problems, and achieve good sound insulation effect and healthy living space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

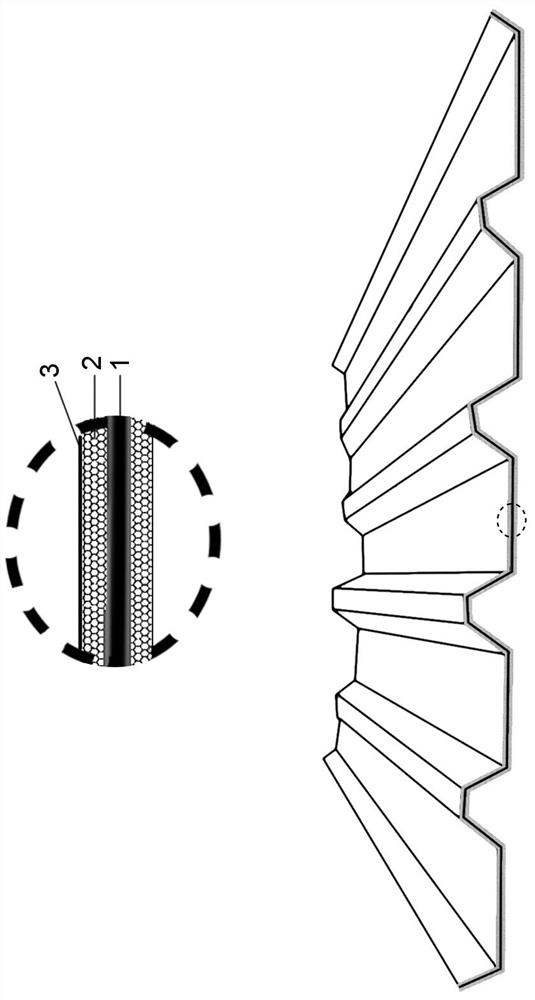

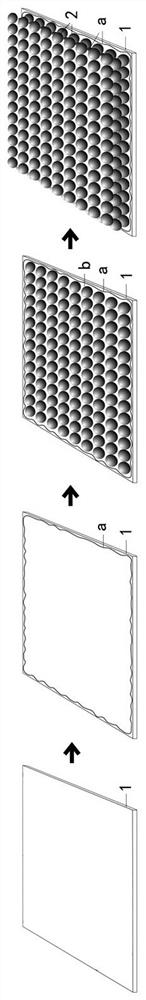

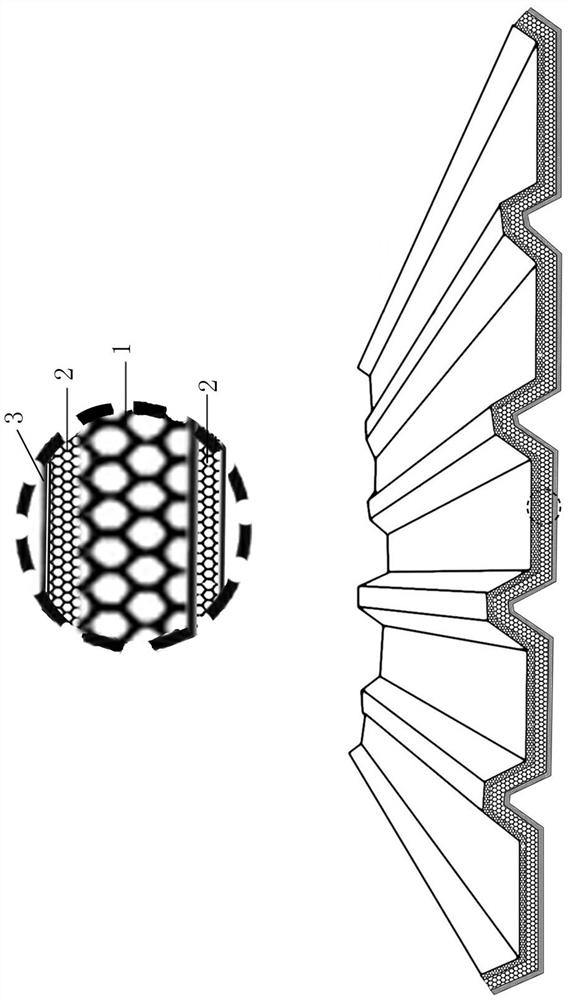

[0015] exist figure 1Among them, the substrate 1 is a resin (or steel plate) roof (or vertical wall panel), and the upper and lower surfaces are each coated with a 0.3 mm three-dimensional matrix layer 2 of hollow microbeads using the "hollow bead matrix layer adhesive coating method" invented by myself. The surface layer of the microbead three-dimensional matrix layer 2 is coated with a titanium dioxide anti-radiation film 3, and the titanium dioxide anti-radiation film 3 is nano-scale ruby-type titanium dioxide. In summer, the outer surface of the hollow microbead three-dimensional matrix laminate with heat insulation, sound insulation, self-cleaning, sterilization and clean air can reflect the heat radiation of the sun with a reflectance ratio of more than 83%, and at the same time absorb most of the heat with a hemispherical emissivity of more than 87%. The three-dimensional matrix layer of hollow microbeads in the hollow microbead three-dimensional matrix layer of heat in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com