Preparation method of three-dimensional network ceramic framework

A technology of ceramic skeleton and three-dimensional network, which is applied in the field of preparation of three-dimensional network ceramic skeleton, can solve problems such as difficulty in mass production, influence of ceramic skeleton strength, and performance reduction of composite materials, and achieve process simplification, easy large-scale batch production, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Example 1, the manufacture of a cylindrical solid rod grid frame ceramic skeleton.

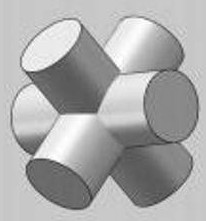

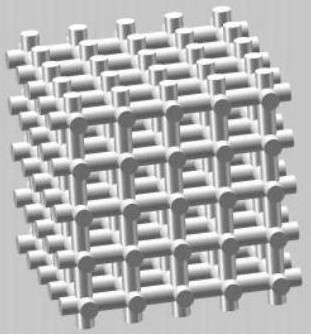

[0018] The topological unit is designed as an orthogonal cylindrical solid cross, such as figure 1 , the length of each side of the cross is 10 mm, the diameter of the cylinder is Φ4 mm, and the dimension from topology to outer contour is 100 mm × 80 mm × 60 mm. This mold is called the positive mold (ceramic firing shrinkage has been added). figure 2 , in the 100 mm × 80 mm × 60 mm three-dimensional space to remove the part of the positive mold, which is the negative mold.

[0019] Use 3D to print the negative model, and the additive is modified paraffin, which is quite simple for 3D printing.

[0020] Inject ZTA ceramic slurry into the hole of the printed negative mold, and there are additional materials of forming agent in the slurry to facilitate injection and solidification.

[0021] After the ceramic slurry is solidified, the whole body is slowly heated at 3-5°C / min, and heated ...

example 2

[0023] Example 2, the three-dimensional network SiC ceramic skeleton of regular triangular pyramid topology.

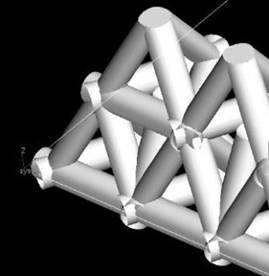

[0024] Design the triangular pyramid topological three-dimensional skeleton model, add ceramic firing shrinkage, the frame edge is composed of straight rod cylinders with a diameter of Φ4 mm, the center distance from the apex to the opposite side is 12 mm, and the topology extends to the space profile in the range of 200 mm × 100 mm × 30 mm , the schematic diagram of the local three-dimensional structure is shown in image 3 shown.

[0025] Remove the positive model designed in [0018] in the three-dimensional space of 200mm×100mm×30mm in the spatial outline, and obtain the negative model, and print the negative model in 3D, the same as in [0013].

[0026] Inject SiC ceramic slurry into the negative mold, the slurry contains additional materials, and is molded by gel method.

[0027] Thereafter, the required three-dimensional network ceramic skeleton was obtained wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com