Safe continuous stationery commodity production and manufacturing equipment and using method thereof

A kind of manufacturing equipment and safe technology, which is applied in the field of safe continuous stationery production and manufacturing equipment, can solve the problems of increasing labor costs, wasting time, and inability to realize continuous production, etc., to facilitate subsequent use and improve mixing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

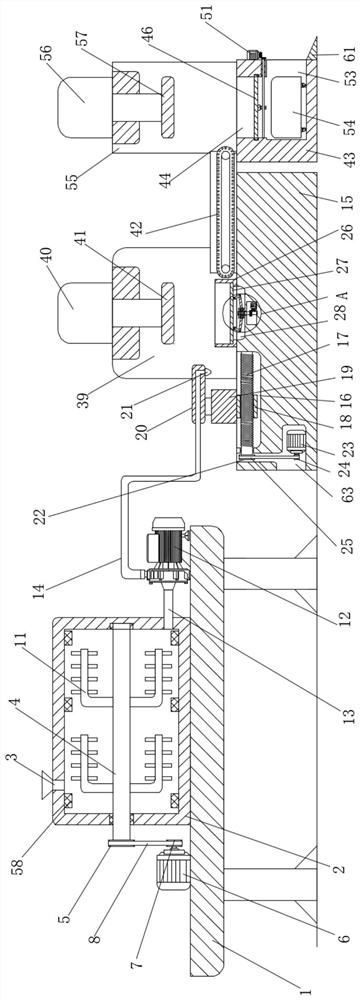

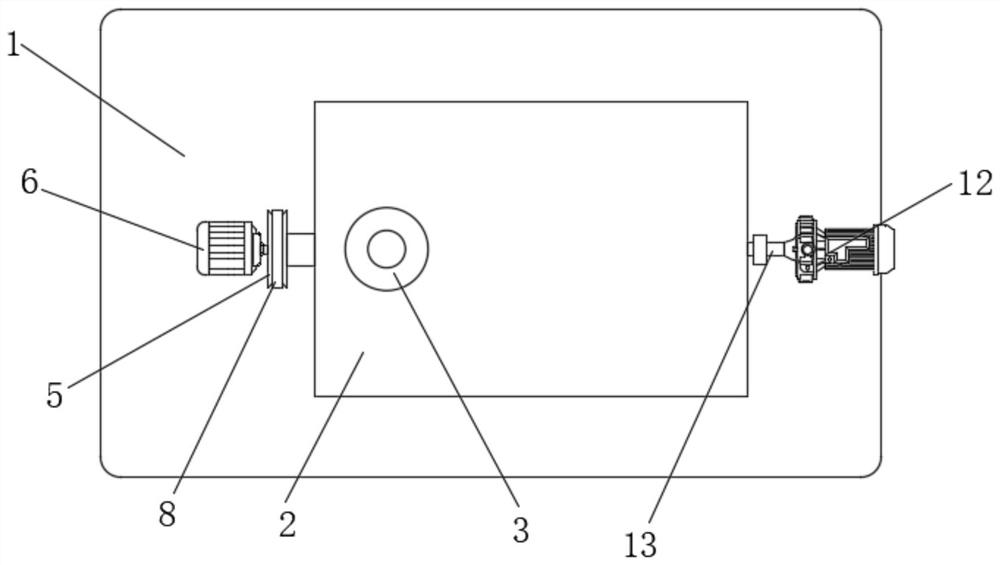

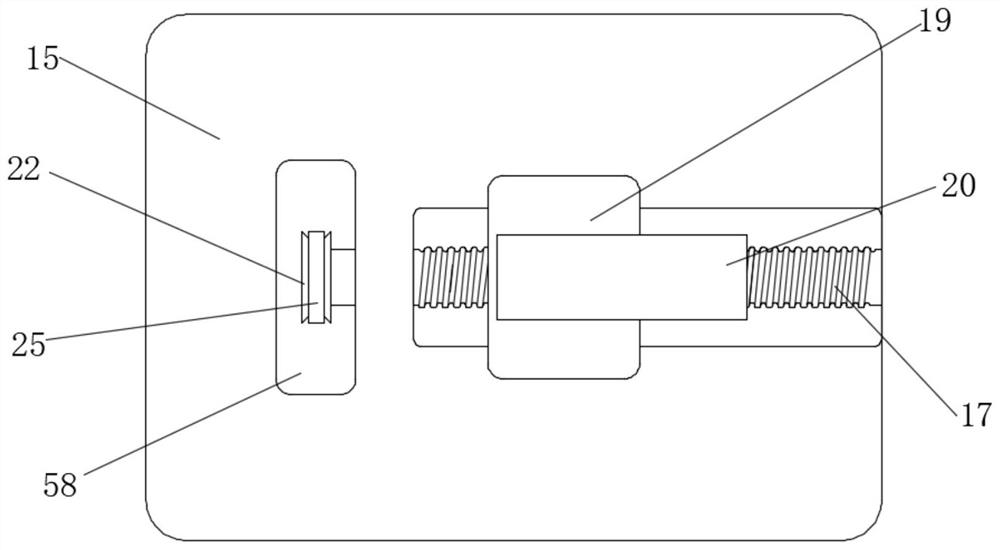

[0046] refer to Figure 1-12 , a kind of safety type continuous stationery production and manufacturing equipment and using method thereof, comprises bottom plate 1, and the top of bottom plate 1 is fixedly connected with stirring box 2, and the top of stirring box 2 is provided with connected feeding hopper 3, and the top of bottom plate 1 The top is provided with a stirring assembly for stirring the raw materials in the mixing tank 2, the top side of the bottom plate 1 is fixedly connected with a pump 12, and the liquid inlet of the pump 12 is fixedly provided with a feeding hose 13, and one end of the feeding hose 13 extends In the mixing tank 2, the liquid outlet of the pump 12 is fixedly sleeved with a discharge hose 14, and one side of the bottom plate 1 is provided with a first workbench 15, and the top of the first workbench 15 is fixedly connected with a mold 26. The top side of the workbench 15 is provided with a material injection assembly for injecting the mold 26....

Embodiment 2

[0060] Embodiment two: if Figure 13-14 As shown, a safe continuous stationery production and manufacturing equipment, the difference between this embodiment and the first embodiment is that: the bottom of the bottom plate 1 is provided with a storage box 10, and the bottom of the mixing box 2 is fixed with a discharge pipe 9 , the bottom end of the discharge pipe 9 runs through the bottom plate 1 and extends into the material storage box 10, the bottom of the feed hose 13 is fixedly sleeved with a pipe 62, and one end of the pipe 62 runs through the bottom plate 1 and extends into the material storage box 10, The outer wall of the discharge pipe 9 is fixedly sleeved with a solenoid valve 59, and the material storage box 10 can store the stirred raw materials in the storage box 10, which is convenient for subsequent use. The outer walls of the feed hose 13 and the pipeline 62 are fixedly sleeved. With valves, the pump 12 can be controlled to extract raw materials from the mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com