Chemical synthesis pharmaceutical solvent recovery wastewater treatment method

A wastewater treatment and chemical synthesis technology, which is applied in chemical instruments and methods, natural water treatment, water/sewage treatment, etc., can solve problems such as waste of resources, and achieve the effect of avoiding waste and realizing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A chemical synthesis pharmaceutical solvent recovery wastewater treatment method, comprising the steps of:

[0035] Step I: Physicochemical treatment, using electrolytic air flotation pretreatment system to pretreat wastewater, electrolytic air flotation pretreatment system includes magnet fluidized bed, micro-electrolysis reactor, Fenton reactor and reaction sedimentation tank set up in sequence, adjacent Pipelines are connected between the equipment; the magnet fluidized bed is divided into three stages, including the aeration section, the reaction section and the separation section. The hydraulic retention time (HRT) of the aeration section is 24h, and the HRT of the separation section is 4h; The reactor is in an aeration state, the HRT of the Fenton reactor is 6h, and the HRT of the reaction sedimentation tank is 5h;

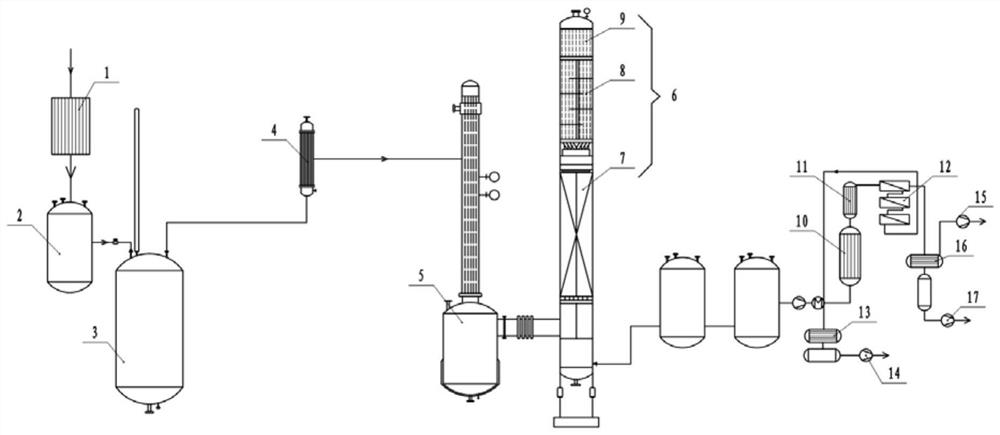

[0036] Step II: solvent recovery, including concentration stage, rectification stage and dehydration stage, such as figure 1 as shown,

[0037] Con...

Embodiment 2

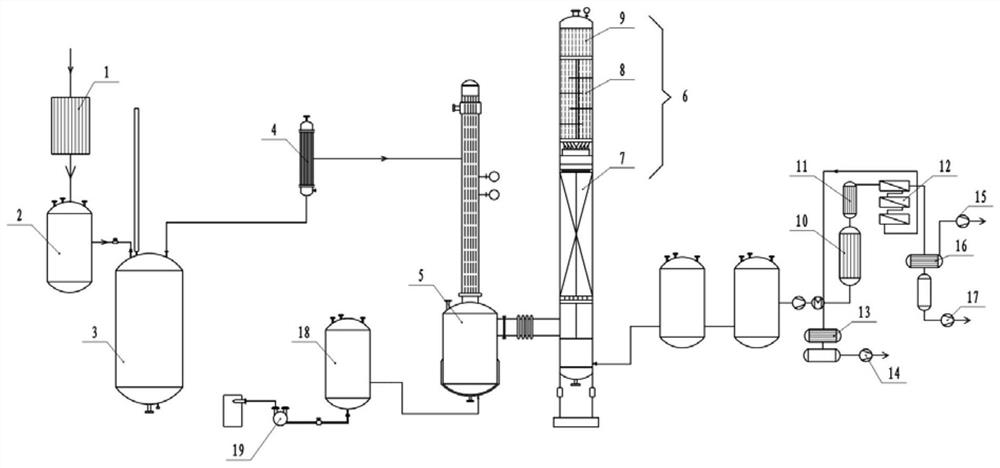

[0042] Such as figure 2 As shown, the difference between this embodiment and the first embodiment is that: in this embodiment, the hot water port is connected with a hot water tank 18 and a water circulation vacuum pump 19 . In this embodiment, the steam in the falling film tower kettle 5 will be condensed into liquid (hot water) after heat exchange, and will be discharged along the hot water outlet. The temporary heating of this part of hot water can be realized by the hot water tank 18 and the water circulation vacuum pump 19. storage and later recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com