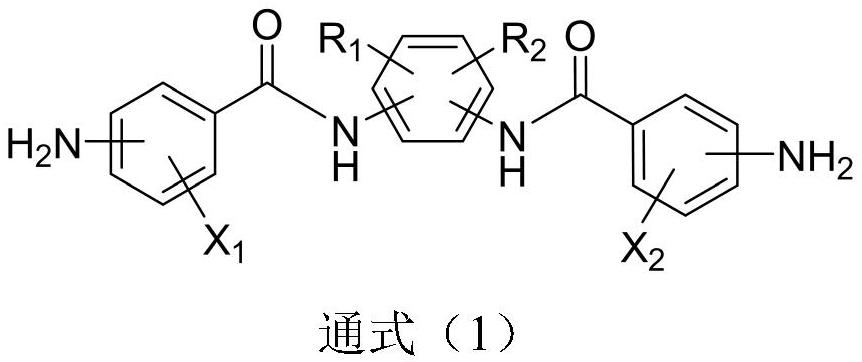

Arylamine compound, liquid crystal aligning agent prepared from arylamine compound, liquid crystal alignment film and liquid crystal display element

A liquid crystal aligning agent and compound technology, which is applied in liquid crystal materials, chemical instruments and methods, organic chemistry, etc., and can solve the problems of low transmittance and reduced brightness of liquid crystal display elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0059] The compound represented by structural formula (1-1) can be synthesized according to the following synthetic route 1:

[0060]

[0061] (1) Synthesis of compound 1-1-a

[0062] In a 1L three-neck round bottom flask, drop 2,4-diaminoiodobenzene (23.40 g, 100 mmol), Et 3 N (50.60g, 500mmol) and 200g toluene, the system was warmed up to 60 ° C, then slowly added dropwise to the system 3-nitro-4-methylbenzoyl chloride (41.91g, 210mmol) and 200g toluene The mixed solution was added dropwise in 0.5 hours, then the system was heated to 80°C and stirred for 8 to 10 hours, followed by TLC until no raw material 2,4-diaminoiodobenzene remained. Then the reaction system was lowered to room temperature, washed three times with 500mL*3 deionized water, and the upper organic phase was de-dried to obtain a light yellow solid, and 500mL of methanol / water mixture was added for beating, and the suspension was filtered and dried at 75 % Yield Compound 1-1-a was obtained.

[0063] (2)...

Synthetic example 2

[0070] The compound represented by structural formula (1-2) can be synthesized according to the following synthetic route 2:

[0071]

[0072] (1) Synthesis of compound 1-2-a

[0073] Add 1,4-diamino-2,5-diiodobenzene (35.99 g, 100 mmol), Et 3N (50.60g, 500 mmoles) and 200 g toluene, the system was warmed up to 60 ° C, then slowly added dropwise to the system 2-nitro-5-fluorobenzoyl chloride (42.75 g, 210 mmoles) and 200 g of toluene The mixture was added dropwise in about 0.5 hours, then the system was heated to 80°C and stirred for 8 to 10 hours, followed by TLC until no raw material 1,4-diamino-2,5-diiodobenzene remained. Then the reaction system was lowered to room temperature, washed three times with 500mL*3 deionized water, and the upper organic phase was de-dried to obtain a light yellow solid, and 500mL of methanol / water mixture was added for beating, and the suspension was filtered and dried to 76 % Yield Compound 1-2-a was obtained.

[0074] (2) Synthesis of co...

Synthetic example 3

[0083] The compound represented by structural formula (1-3) can be synthesized according to the following synthetic route 3:

[0084]

[0085] (1) Synthesis of compound 1-3-a

[0086] In a 1L three-neck round bottom flask, drop 2,4-diaminoiodobenzene (23.40 g, 100 mmol), Et 3 N (50.60g, 500mmol) and 200g toluene, the system was warmed up to 60 ° C, and then slowly added dropwise to the system a mixture of p-nitrobenzoyl chloride (38.97g, 210mmol) and 200g toluene, about 0.5 After hours of dropwise addition, the system was heated to 80°C and stirred for 8 to 10 hours, followed by TLC until no raw material 2,4-diaminoiodobenzene remained. Then the reaction system was lowered to room temperature, washed three times with 500mL*3 deionized water, the upper organic phase was de-dried to obtain a light yellow solid, and 500mL of methanol / water mixture was added for beating, and the suspension was filtered and dried to 73 % Yield Compound 1-3-a was obtained.

[0087] (2) Synthes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com