Removable pressure-sensitive adhesive composition

A technology of pressure-sensitive adhesives and compositions, applied in the direction of adhesive types, ester copolymer adhesives, coatings, etc., can solve the phenomenon of removable pressure-sensitive adhesive residue, poor aging resistance, It can remove problems such as poor construction of pressure-sensitive adhesives, and achieve the effects of convenient production and operation, high peel strength, and no adhesive residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

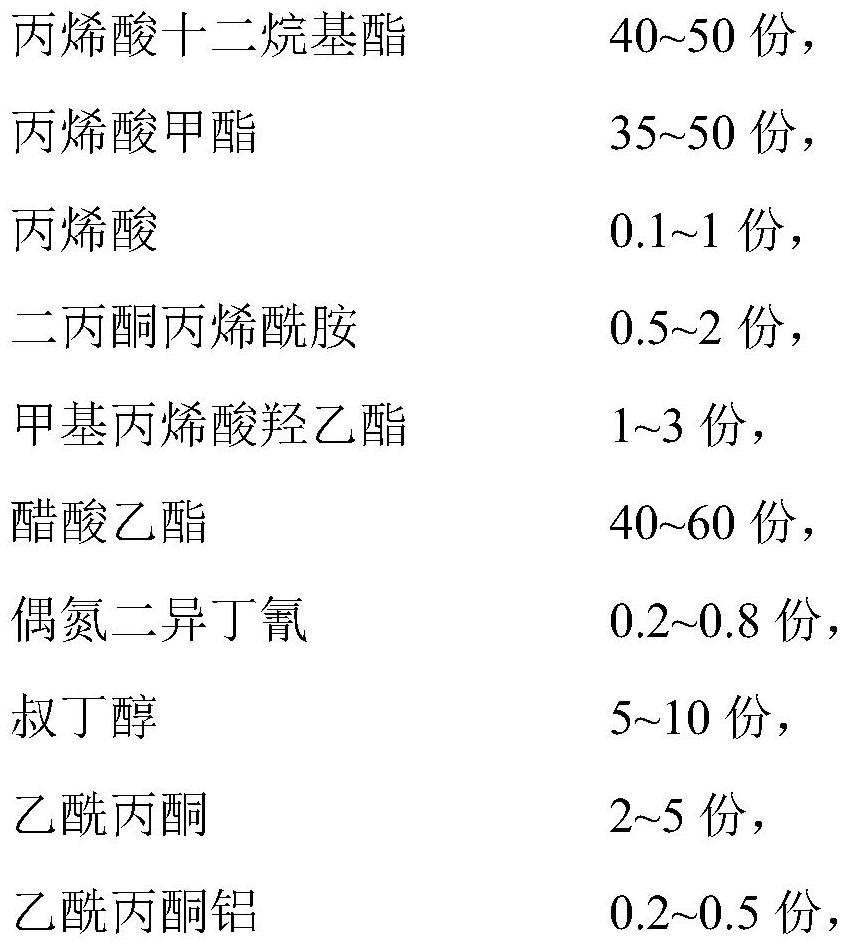

[0051] A removable pressure-sensitive adhesive composition, comprising the following components by weight:

[0052]

[0053]

[0054] Its preparation steps are as follows:

[0055] Q1: Put the lauryl acrylate, methyl acrylate, acrylic acid, diacetone acrylamide, hydroxyethyl methacrylate, ethyl acetate, and azobisisobutylcyanide in the above parts by weight into the container, and turn it at 200 rpm Stir at a speed of 1 / min for 15 minutes to prepare mixed solution A;

[0056] Q2: Take 30% of the total weight of the above-mentioned mixed solution A and put it into the reaction kettle, fully stir it for 10 minutes at room temperature, the stirring speed is 80 rpm, and continuously feed nitrogen into the reaction kettle while stirring. After the stirring is completed, Gradually raise the temperature in the reactor to 75°C and continue the reaction for 30 minutes;

[0057] Q3: Take the remaining mixed liquid A in the dropping funnel, drop it into the above reaction kettle ...

Embodiment 2

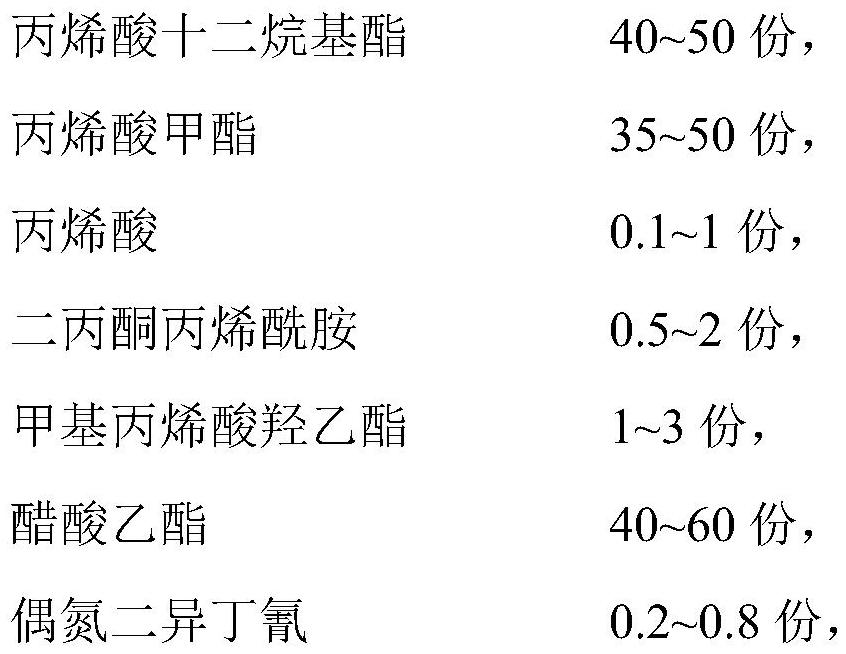

[0067] A removable pressure-sensitive adhesive composition, comprising the following components by weight:

[0068]

[0069] Its preparation steps are as follows:

[0070] Q1: Put the lauryl acrylate, methyl acrylate, acrylic acid, diacetone acrylamide, hydroxyethyl methacrylate, ethyl acetate, and azobisisobutylcyanide in the above parts by weight into the container, and turn it at 300 rpm Stir at a speed of 1 / min for 30 minutes to prepare mixed solution A;

[0071] Q2: Take 45% of the total weight of the above-mentioned mixed liquid A and put it into the reactor, fully stir it for 30 minutes at room temperature, the stirring speed is 200 rpm, and continuously feed nitrogen into the reactor while stirring. After the stirring is completed, Gradually raise the temperature in the reactor to 80°C and continue the reaction for 120 minutes;

[0072] Q3: Take the remaining mixed liquid A in the dropping funnel, drop it into the above reaction kettle at a constant speed and comp...

Embodiment 3

[0082] A removable pressure-sensitive adhesive composition, comprising the following components by weight:

[0083]

[0084] Its preparation steps are as follows:

[0085] Q1: Put the lauryl acrylate, methyl acrylate, acrylic acid, diacetone acrylamide, hydroxyethyl methacrylate, ethyl acetate, and azobisisobutylcyanide in the above weight parts into the container, and turn it at 250 rpm Stir at a speed of 1 / min for 22 minutes to prepare mixed solution A;

[0086] Q2: Take 38% of the total weight of the above-mentioned mixed solution A and put it into the reaction kettle, fully stir it at room temperature for 20 minutes, the stirring speed is 140 rpm, and continuously feed nitrogen into the reaction kettle while stirring. After the stirring is completed, Gradually raise the temperature in the reactor to 78°C and continue the reaction for 75 minutes;

[0087] Q3: Take the remaining mixed liquid A in the dropping funnel, drop it into the above reaction kettle at a constant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com