Auxiliary power generation system driven by stamping turbine and using method

A technology of auxiliary power generation and auxiliary generator, applied in the direction of electrical components, circuit devices, emergency power supply arrangements, etc., to improve the emergency power supply time, solve the mutual matching of the system, and solve the effects of insufficient power supply capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] This part is the embodiment of the present invention, which is used to explain and illustrate the technical solution of the present invention.

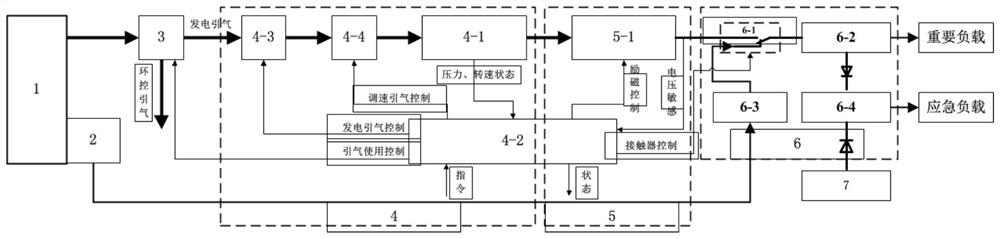

[0025] An auxiliary power generation system driven by a ram turbine, comprising an engine 1, a main generator 2, a bleed air valve 3, an auxiliary power unit 4, an auxiliary power generation system 5, and a power distribution system 6, the engine 1 is mechanically connected to the main generator 2, The current generated by the main generator 2 is transmitted to the power distribution system 6; the rear bleed air passage of the engine 1 is connected to the bleed air valve 3, and the bleed air valve 3 controls the distribution of the air flow to the environmental control system and the auxiliary power unit 4, which includes the turbine The power unit 4-1 and the integrated controller 4-2, the integrated controller 4-2 is connected to and controls the bleed air valve 3, the turbine power unit 4-1 is rotated by the bleed air of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com