Piston type flow regulating valve

A flow control valve and piston type technology, applied in the field of flow control valves, can solve the problems of increasing the diameter of the valve body, increasing the volume of the flow control valve, and the long distance of axial movement of the sliding sleeve, so as to reduce the diameter and drive the device. Compactness and improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

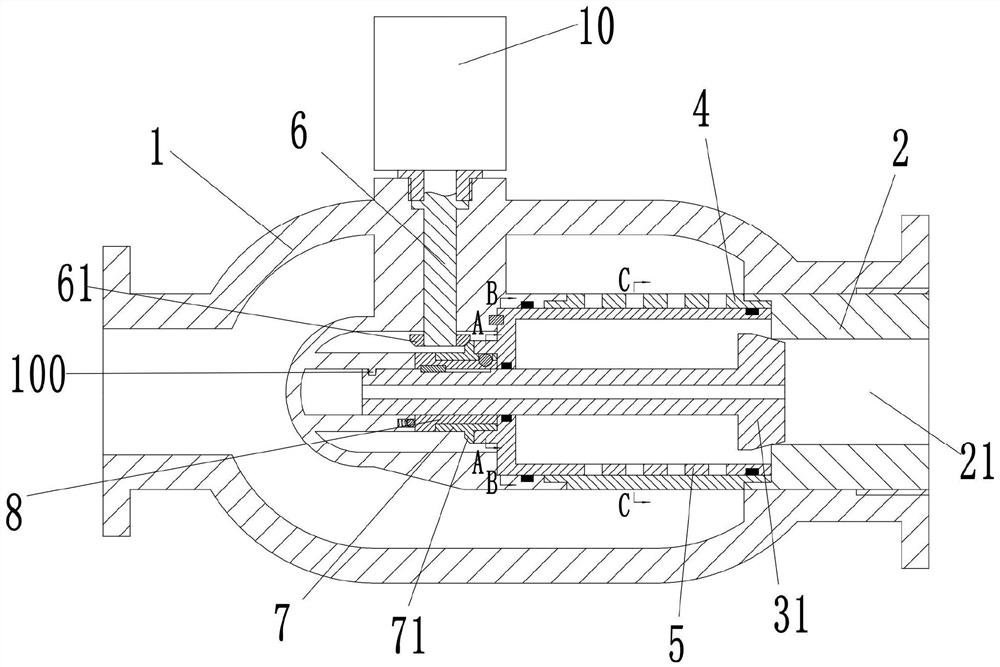

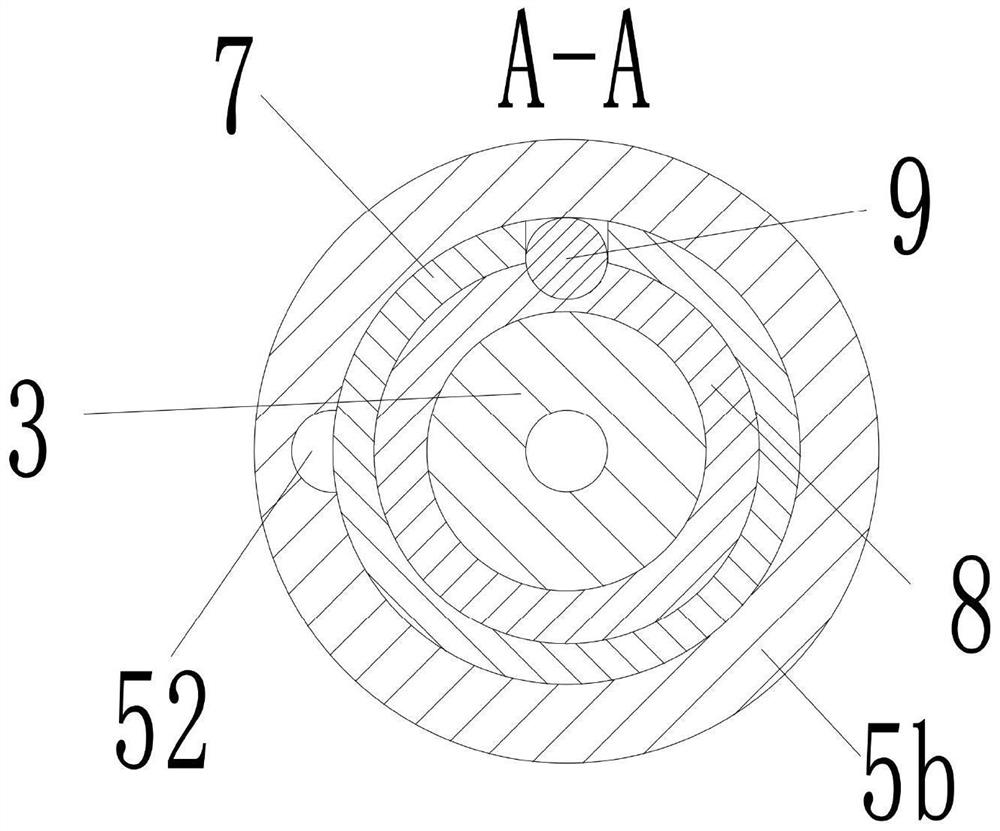

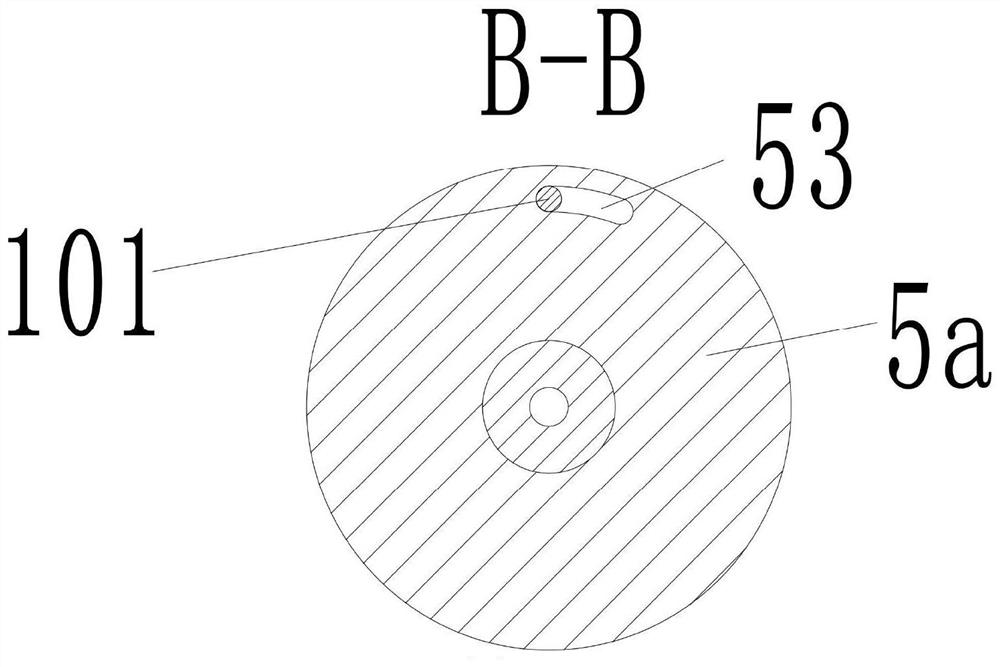

[0031] see Figure 1-13 As shown, the present invention provides a piston-type flow control valve, including a valve body 1, a valve chamber 1a is arranged inside the valve body 1, an inlet pipe 1b is arranged at the left end of the valve body 1, and an outlet pipe 1c is arranged at the right end ; The outlet pipe 1c is fixed with a valve block 2, and the valve block 2 is provided with a valve hole 21 along the left and right directions; the inner side wall of the valve cavity 1a is extended with a bump 1d, and the inside of the bump 1d A valve slot 1e with an open right end is provided, and a protruding shaft 1f extends rightward from the left end of the valve slot 1e. A shaft hole 1g with an opening at the right end is provided in the protruding shaft 1f, and a valve stem is provided in the shaft hole 1g. 3. The valve stem 3 is provided with a spiral groove 32 on the outside of one end extending into the shaft hole 1g, and the side wall of the shaft hole 1g is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com