Environment-friendly biomass combustion furnace

A biomass burning furnace and environmental protection technology, applied in the combustion method, combustion equipment, fuel supply and other directions, can solve the problems of increased production cost, vulnerable connection parts, laborious and other problems, to increase the service life, avoid waste, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

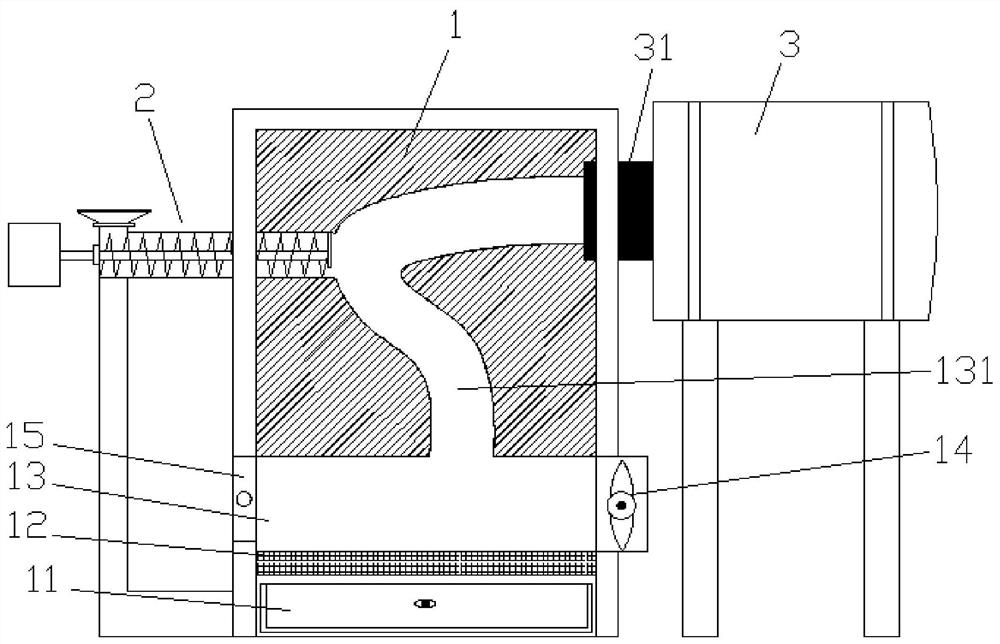

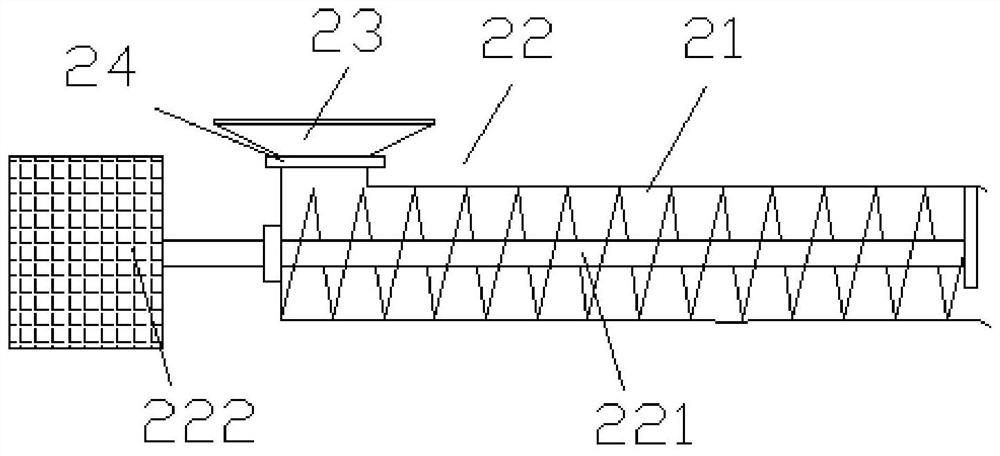

[0018] Embodiment one: Figure 1-Figure 2 Shown is an environmentally friendly biomass burning furnace, which is mainly composed of a furnace body 1 and a feeding mechanism 2, the discharge end of the feeding mechanism 2 is placed in the furnace body 1 Inside, the feeding end of the feeding mechanism 2 is placed outside the furnace body 1, and the furnace wall of the furnace body 1 is provided with a heat collecting port, and the heat collecting port is connected to the drying chamber 3 through the connecting head 31. connected to the drying chamber through the heat collecting port and the connecting head, so that the heat in the furnace can enter the drying chamber, and the feeding mechanism automatically feeds the material, eliminating the need for manual addition of raw materials; the furnace body 1 is mainly composed of: ash collection box 11. Furnace tooth 12, combustion chamber 13, fan 14 and observation window 15 are combined. The ash collection box 11 is arranged at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com