Red-light plastic scintillator as well as preparation method and application thereof

A plastic scintillator, scintillator technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the cost difference, limit the size and application field of plastic scintillator, reduce scintillator transparency, mechanical strength, stability, etc. problems, to achieve the effect of prolonged mechanical strength, considerable commercial application prospects, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

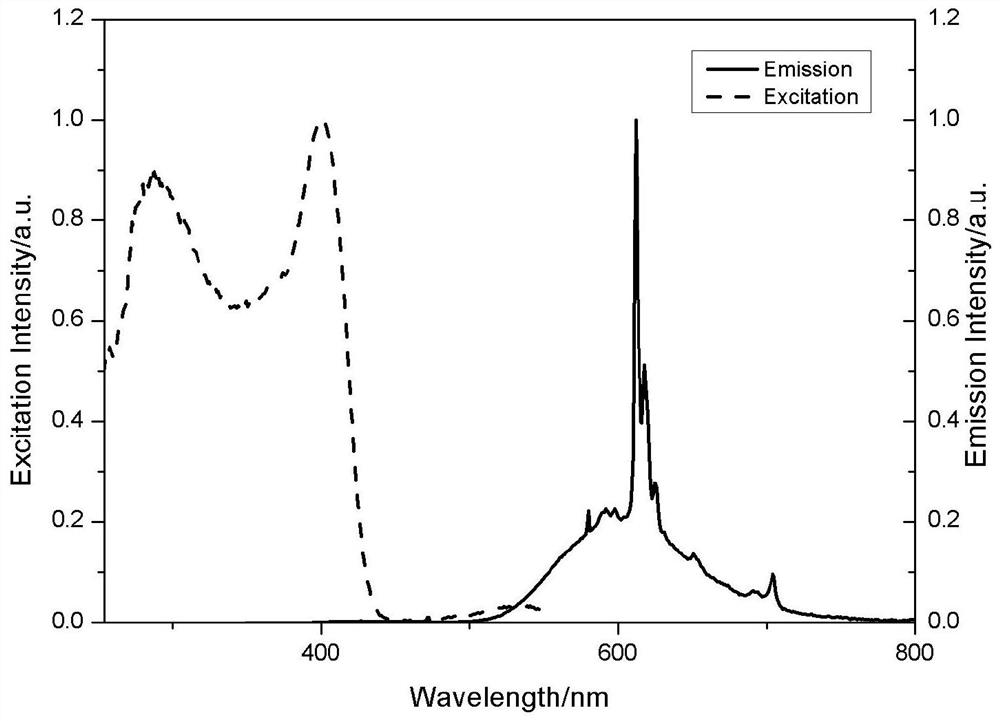

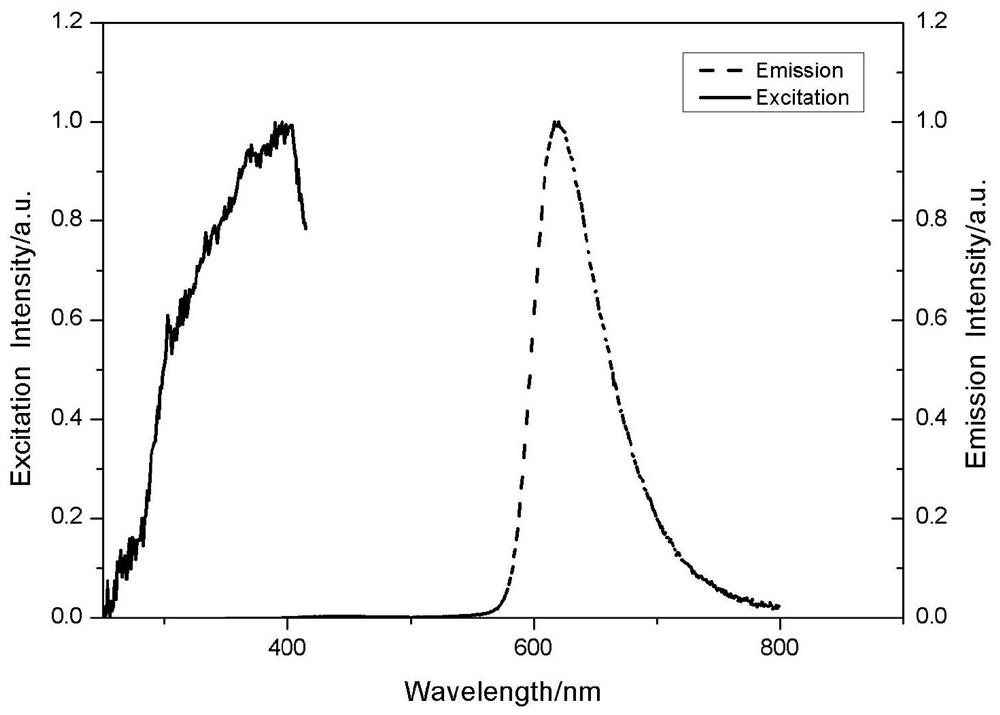

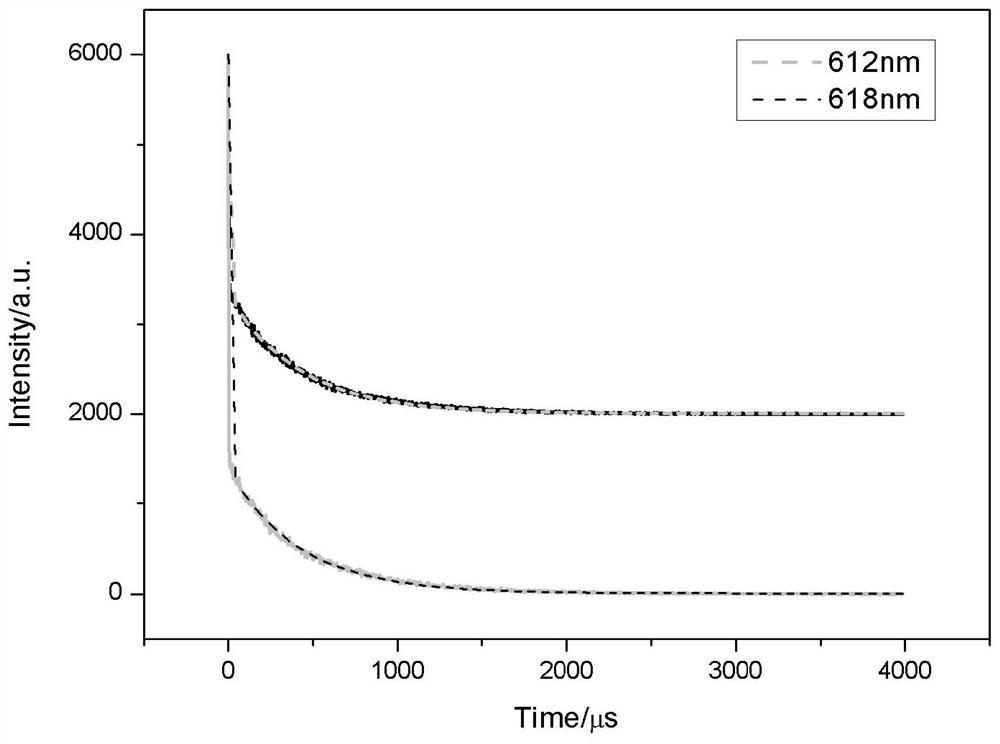

[0044] (1) 0.01g of 1,1,4,4-tetraphenyl-1,3-butadiene (TPB), 0.001g of 4-(dicyanomethylene)-2-methyl -6-(4-Dimethylaminostyryl)-4H-pyran (DCM), 0.125g of Eu(DBM) 3 The styrene (St) of Phen and 3.75g is mixed and stirred to form a solution and is recorded as solution A; The azobisisobutyronitrile (AIBN) of 0.001g and the acrylonitrile (AN) of 1.25g are mixed and stirred to form a solution and recorded It is solution B; finally, mix uniformly stirred solution A and solution B and ultrasonically homogenize to obtain Eu(DBM)3Phen / TPB / DCM / AS precursor solution. Among them, the mass ratio of styrene and acrylonitrile is 75:25.

[0045] (2) Add the precursor solution into a silicate glass ampoule and mix well. Then first vacuumize for 3.0min, then blow nitrogen for 2.0min, repeat the above operation at least 3 times. Finally, it is sealed under vacuum conditions.

[0046] (3) First keep warm at 50°C for 12 hours, then raise the temperature by 5°C every 6 hours to 100°C, and keep ...

Embodiment 2

[0048] (1) 0.01g of 1,1,4,4-tetraphenyl-1,3-butadiene (TPB), 0.002g of 4-(dicyanomethylene)-2-methyl -6-(4-Dimethylaminostyryl)-4H-pyran (DCM), 0.125g of Eu(DBM) 3 The styrene (St) of Phen and 3.75g is mixed and stirred to form a solution and is recorded as solution A; The azobisisobutyronitrile (AIBN) of 0.001g and the acrylonitrile (AN) of 1.25g are mixed and stirred to form a solution and recorded It is solution B; finally, mix uniformly stirred solution A and solution B and ultrasonically homogenize to obtain Eu(DBM)3Phen / TPB / DCM / AS precursor solution. Among them, the mass ratio of styrene and acrylonitrile is 75:25.

[0049] (2) Add the precursor solution into a silicate glass ampoule and mix well. Then first vacuumize for 3.0min, then blow nitrogen for 2.0min, repeat the above operation at least 3 times. Finally, it is sealed under vacuum conditions.

[0050] (3) First keep warm at 50°C for 12 hours, then raise the temperature by 5°C every 6 hours to 100°C, and keep ...

Embodiment 3

[0052] (1) 0.01g of 1,1,4,4-tetraphenyl-1,3-butadiene (TPB), 0.003g of 4-(dicyanomethylene)-2-methyl -6-(4-Dimethylaminostyryl)-4H-pyran (DCM), 0.125g of Eu(DBM) 3 The styrene (St) of Phen and 3.75g is mixed and stirred to form a solution and is recorded as solution A; The azobisisobutyronitrile (AIBN) of 0.001g and the acrylonitrile (AN) of 1.25g are mixed and stirred to form a solution and recorded It is solution B; finally, mix uniformly stirred solution A and solution B and ultrasonically homogenize to obtain Eu(DBM)3Phen / TPB / DCM / AS precursor solution. Among them, the mass ratio of styrene and acrylonitrile is 75:25.

[0053] (2) Add the precursor solution into a silicate glass ampoule and mix well. Then first vacuumize for 3.0min, then blow nitrogen for 2.0min, repeat the above operation at least 3 times. Finally, it is sealed under vacuum conditions.

[0054] (3) First keep warm at 50°C for 12 hours, then raise the temperature by 5°C every 6 hours to 100°C, and keep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com