Environment-friendly dedusting device for cement plant

A technology of dust removal device and cement plant, applied in the directions of transportation and packaging, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of affecting the filtering effect of the filter screen, residual filter screen, excessive dust in the environment, etc., to improve the practical application effect, improve the scraping effect, ensure the effect of the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

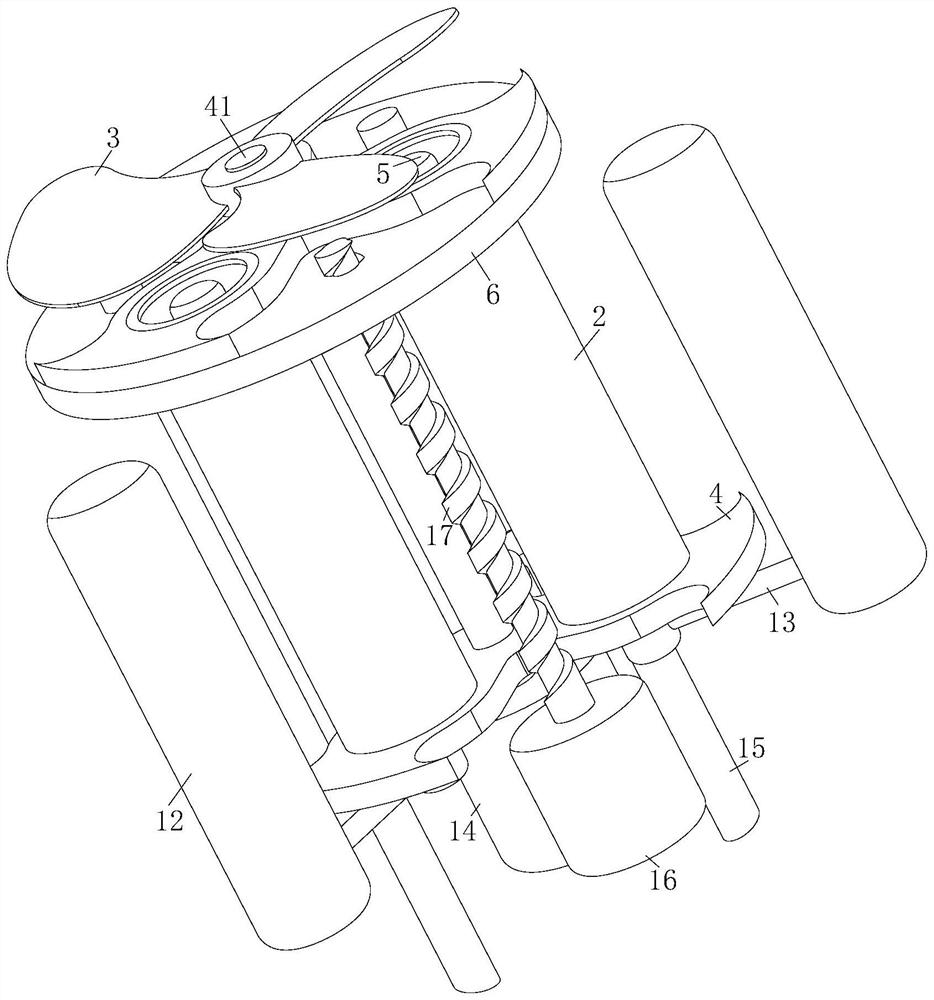

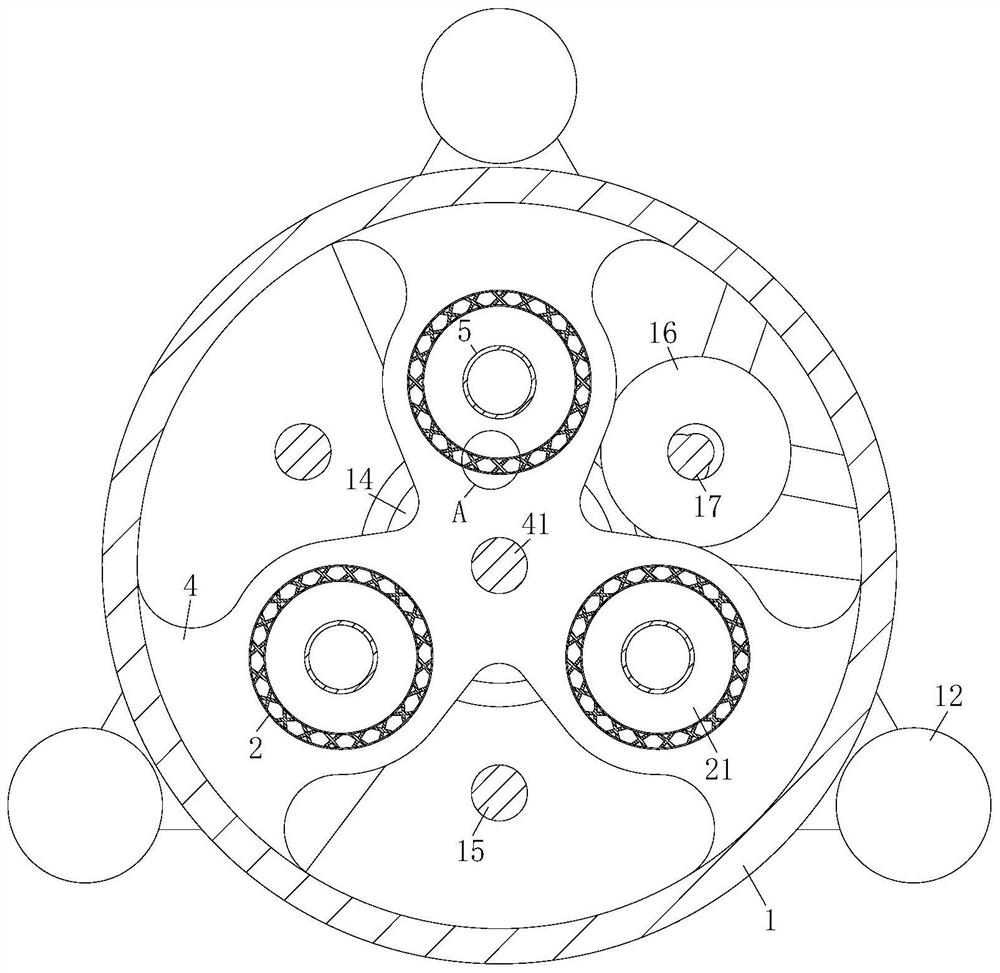

[0031] As an embodiment of the present invention, grooves 62 are arranged on the groove wall of the circular groove 61, and the grooves 62 are evenly distributed on the groove wall of the circular groove 61, and a scraper 63 is slidably connected in the groove 62 , the groove 62 is also provided with a spring 64; one end of the spring 64 is connected to the groove bottom of the groove 62, and the other end is connected to the scraper 63; Outer wall contact; when working, if the round groove 61 at the upper end of the scraper 6 contacts the outer wall of the filter cartridge 2 too tightly, it will cause the outer wall of the filter cartridge 2 to be scratched. When the contact is too loose, it will affect the scraping effect of the dust on the outer wall of the filter cartridge 2; Groove 62, groove 62 is provided with scraper 63 and spring 64, so scraper 63 is in contact with the outer wall of filter cartridge 2 under the action of spring 64, makes spring 64 play a buffering ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com