BiOCl/expanded perlite floating photocatalyst and application thereof

A technology of expanded perlite and photocatalyst, which is applied in the direction of physical/chemical process catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of low utilization rate of light energy, secondary pollution, powerlessness, etc. Energy utilization is low, the connection strength is enhanced, and the effect of uniform distribution is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

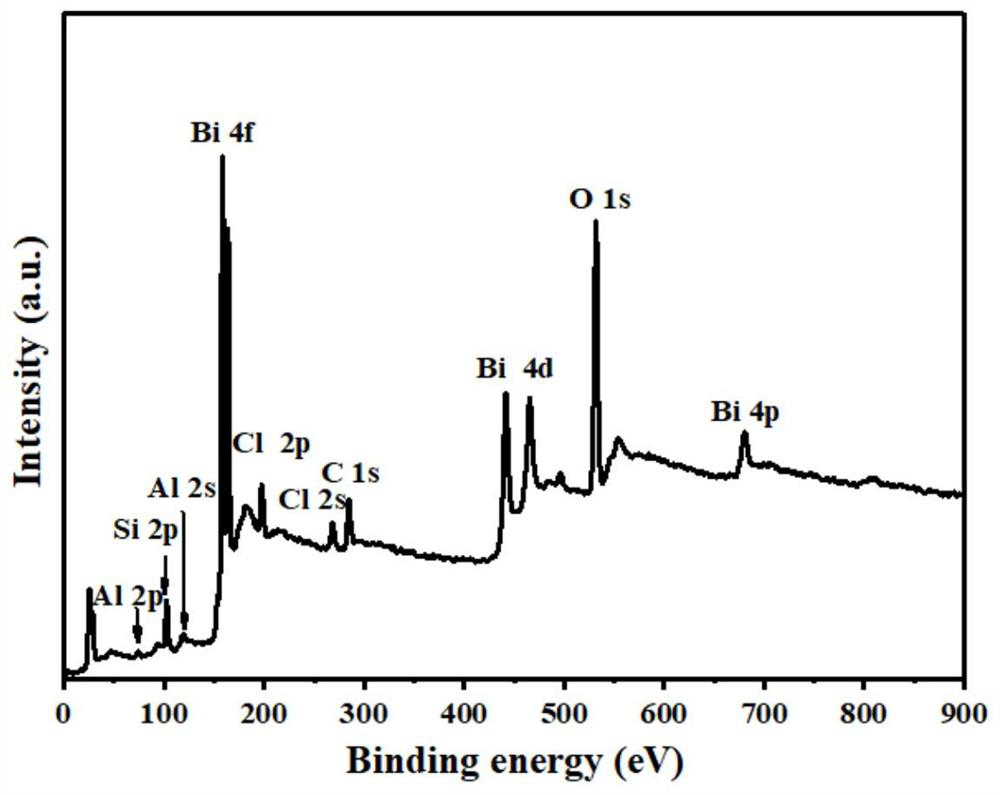

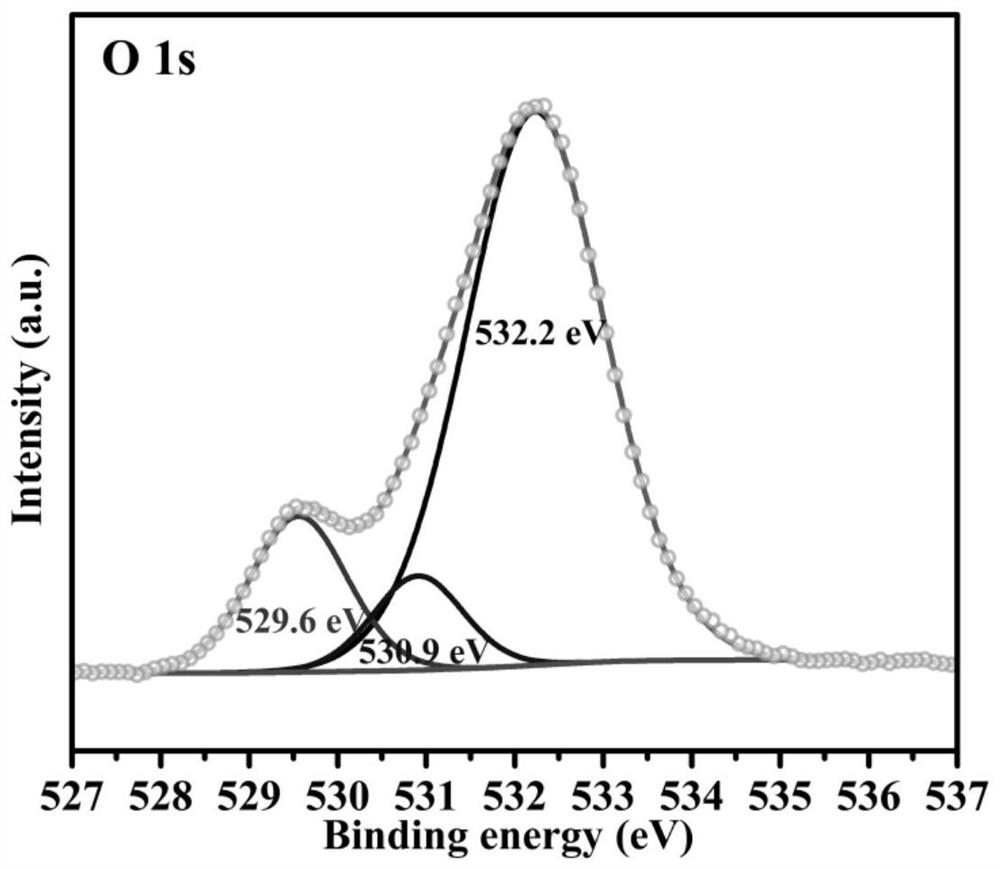

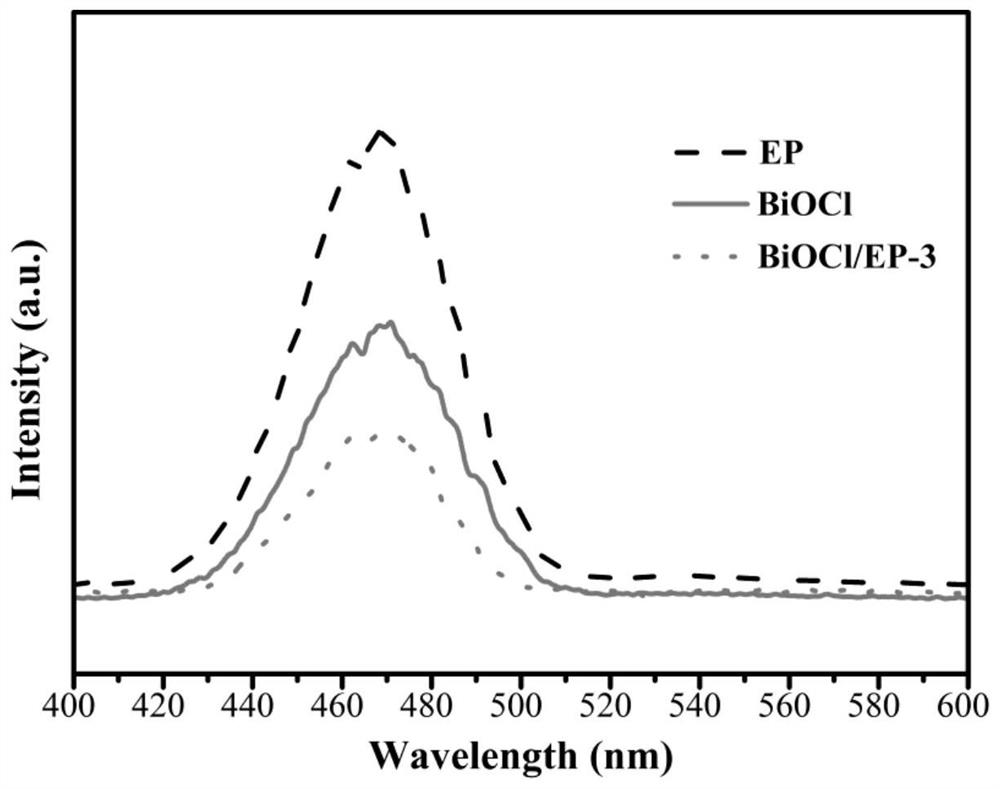

Embodiment 1

[0038] 1g of Bi(NO 3 ) 3 ·5H 2 O was dissolved in 6ml of ethylene glycol solution, which was recorded as solution A; an equimolar amount of KCl was dissolved in an equal volume of deionized water, which was recorded as solution B. Add 0.35g of expanded perlite to solution A, let it stand for 60min, filter it out and add it to the KCl solution. Afterwards, the resulting mixture was transferred to a polytetrafluoroethylene-lined high-pressure hydrothermal reactor and heated at 160 °C for 45 min. After cooling to room temperature, the resulting product was dried at 80 °C for 15 h. Then BiOCl / expanded perlite was calcined in a tube furnace at 450°C for 60min to obtain BiOCl / expanded perlite composite BiOCl / EP-1.

Embodiment 2

[0040] 2g of Bi(NO 3 ) 3 ·5H 2 O was dissolved in 6ml of ethylene glycol solution, which was recorded as solution A; an equimolar amount of KCl was dissolved in an equal volume of deionized water, which was recorded as solution B. Add 0.35g of expanded perlite to solution A, let it stand for 60min, filter it out and add it to the KCl solution. Afterwards, the resulting mixture was transferred to a polytetrafluoroethylene-lined high-pressure hydrothermal reactor and heated at 160 °C for 45 min. After cooling to room temperature, the resulting product was dried at 80 °C for 15 h. Then BiOCl / expanded perlite was calcined in a tube furnace at 450°C for 60min to obtain BiOCl / expanded perlite composite BiOCl / EP-2.

Embodiment 3

[0042] 3g of Bi(NO 3 ) 3 ·5H 2 O was dissolved in 6ml of ethylene glycol solution, which was recorded as solution A; an equimolar amount of KCl was dissolved in an equal volume of deionized water, which was recorded as solution B. Add 0.35g of expanded perlite to solution A, let it stand for 60min, filter it out and add it to the KCl solution. Afterwards, the resulting mixture was transferred to a polytetrafluoroethylene-lined high-pressure hydrothermal reactor and heated at 160 °C for 45 min. After cooling to room temperature, the resulting product was dried at 80 °C for 15 h. Then BiOCl / expanded perlite was calcined in a tube furnace at 450°C for 60min to obtain BiOCl / expanded perlite composite BiOCl / EP-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com