Wire drawing device of ultra-micro wire for enameled wire production and wire drawing method of wire drawing device

An enameled wire and wire technology, used in the direction of reducing the size of conductors/cables, electrical components, circuits, etc., can solve problems such as poor adjustability, inability to ensure that the enameled wire transmission is in a straight state, and inability to detect differential speeds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

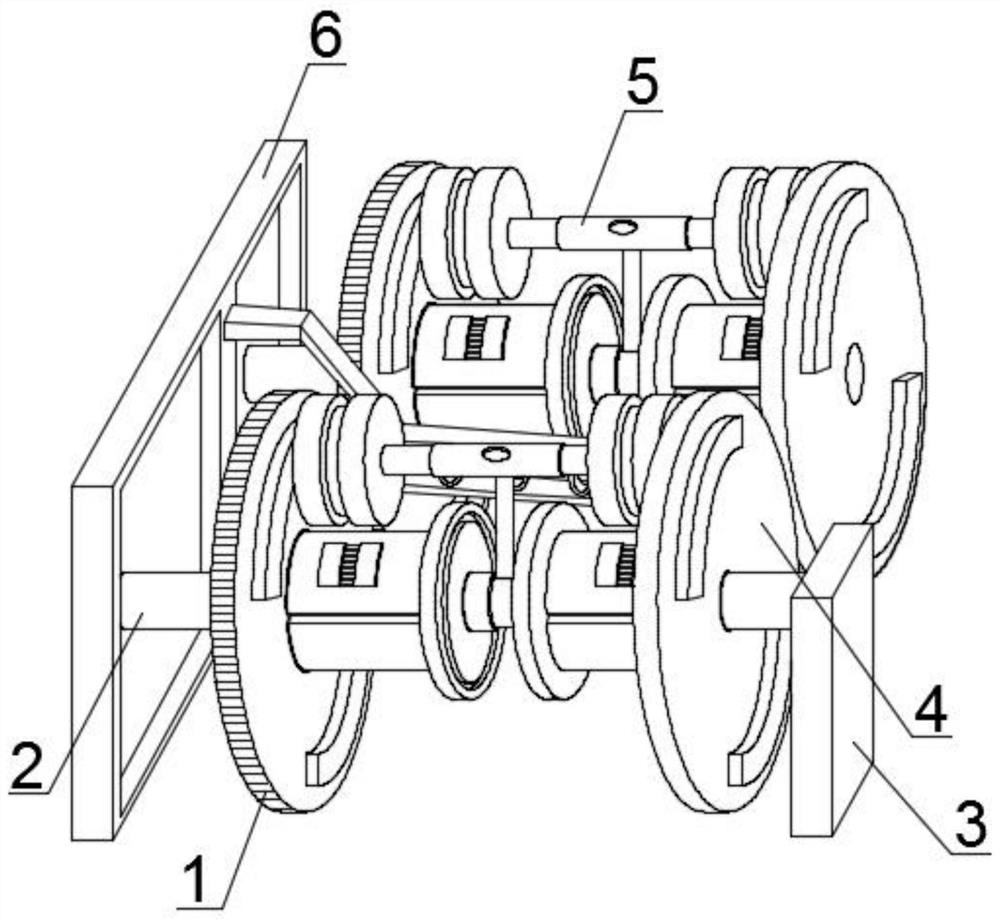

[0033] Such as figure 1 , 2 As shown in and 7, a wire drawing device and a wire drawing method for ultra-fine wire rods for enameled wire production, including a transmission mechanism 1, a drive mechanism 4 and a differential speed adjustment mechanism 5, the inner cavity of the transmission mechanism 1 and the drive mechanism 4 is provided with a fixed Cross bar 2, the other end of fixed cross bar 2 is fixedly connected with fixed vertical box 3, and the side end of assembling plate 16 is equipped with permanent magnet block 17, and permanent magnet block 17 is a kind of M shape member, and permanent magnet block 17 is embedded with Ring groove 42 cooperates, and the height that permanent magnet block 17 sets should be less than the depth that inlay ring groove 42 sets, is provided with differential speed adjustment mechanism 5 through between transmission mechanism 1 and driving mechanism 4, and transmission mechanism 1 and driving mechanism The mechanism 4 is installed on...

Embodiment 2

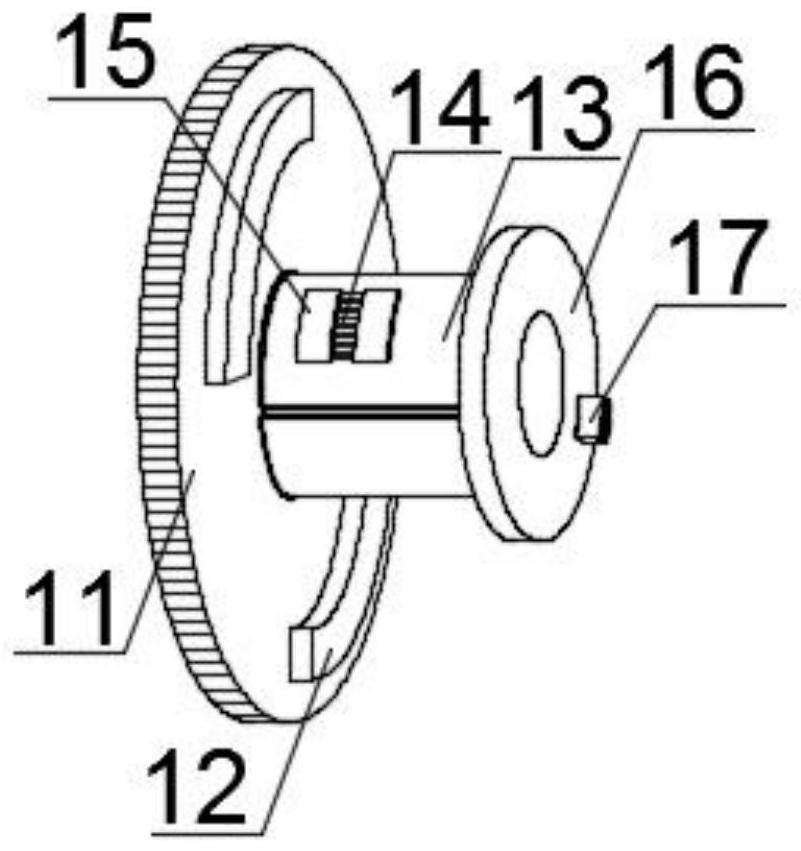

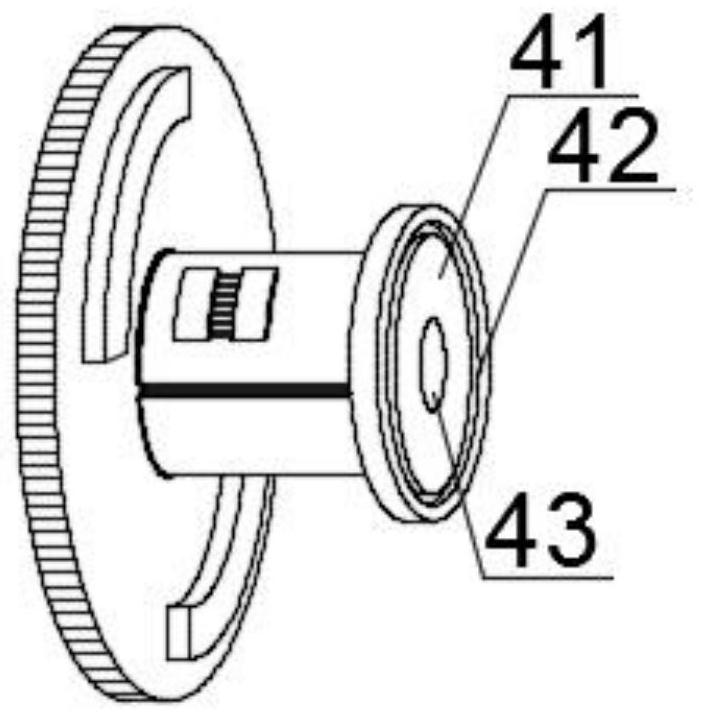

[0035] Such as figure 2 and 3As shown, a wire drawing device and a wire drawing method for ultra-fine wires for enameled wire production, the transmission mechanism 1 includes a rotating disk 11, an aluminum strip 12, a receiving horizontal cylinder 13, a limiting cavity 14, a limiting edge block 15, and an assembly plate 16 and permanent magnet block 17, the side end of rotating disc 11 is provided with aluminum strip 12 annularly, and the side end of rotating disc 11 is provided with accepting horizontal tube 13, and the outer end of accepting horizontal tube 13 is provided with limit cavity 14, and the limit cavity The two ends of 14 are provided with limited edge blocks 15, and the other end of the horizontal cylinder 13 is fixedly connected with the assembly disk 16. The drive mechanism 4 includes an assembly disk body 41, an embedded ring groove 42 and a through hole 43, and the assembly disk body 41 The annular array on the side end surface is provided with an embedde...

Embodiment 3

[0037] Such as Figure 4 , 5 Shown in and 6, a kind of enameled wire production uses the wire drawing device of ultra-fine wire rod and wire drawing method thereof, and differential speed adjustment mechanism 5 comprises hollow cylinder 51, threaded rod 52, friction roller 53, cylinder 54 and air vent 55, the hollow cylinder 51 The inner cavity is interspersed with a threaded rod 52, the two ends of the threaded rod 52 are provided with friction rollers 53, the bottom end of the hollow cylinder 51 is provided with a cylinder 54, and the top of the hollow cylinder 51 is provided with a vent hole 55, between the transmission mechanism 1 and the driving mechanism 4 In the process of non-contact electromagnetic transmission, the transmission mechanism 1 drives the driving mechanism 4 to move in the same direction, and at this time there will be a slight speed difference between the two, and the running speed of the transmission mechanism 1 will always be greater than or equal to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com