Steel wire rope symmetrical linkage chuck

A technology of steel wire rope and wire rope assembly, applied in the field of metal processing equipment, can solve the problems of slow automatic clamping or loosening of pipes, unfavorable equipment processing efficiency, poor equipment use effect, etc., to achieve fast installation and debugging, and reduce auxiliary clamping time. , Automatic centering and clamping, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

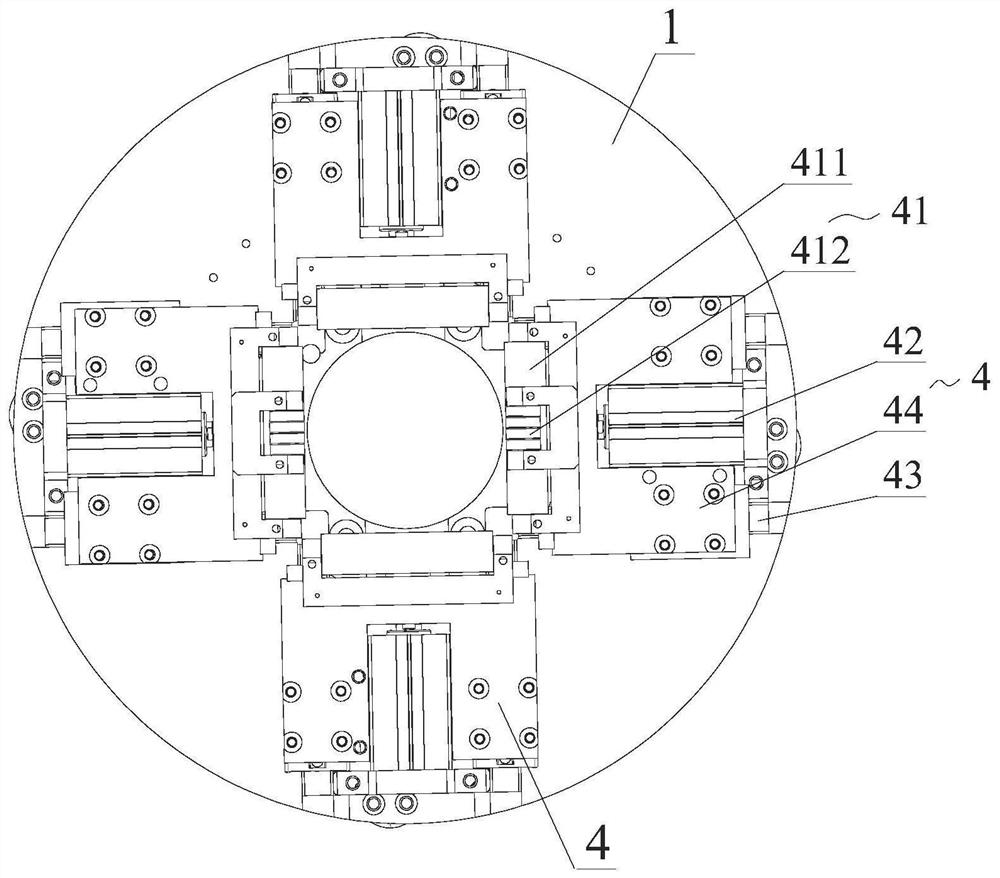

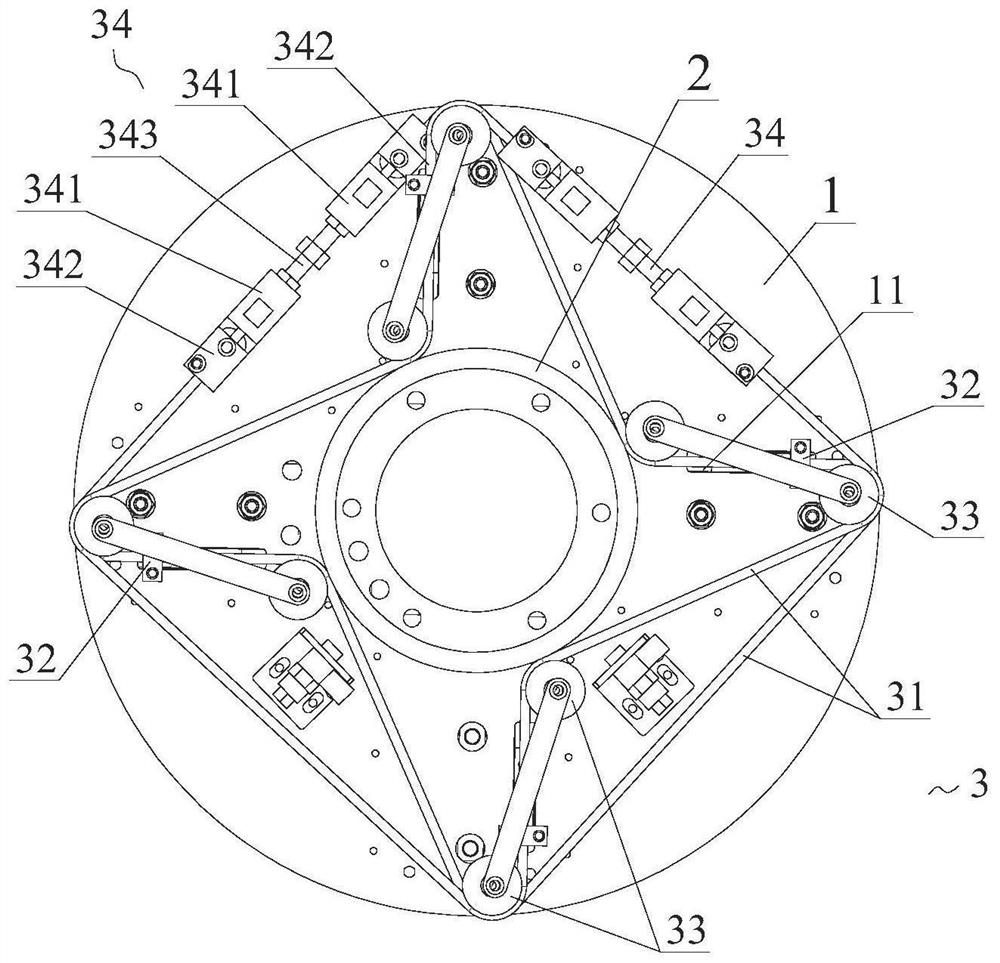

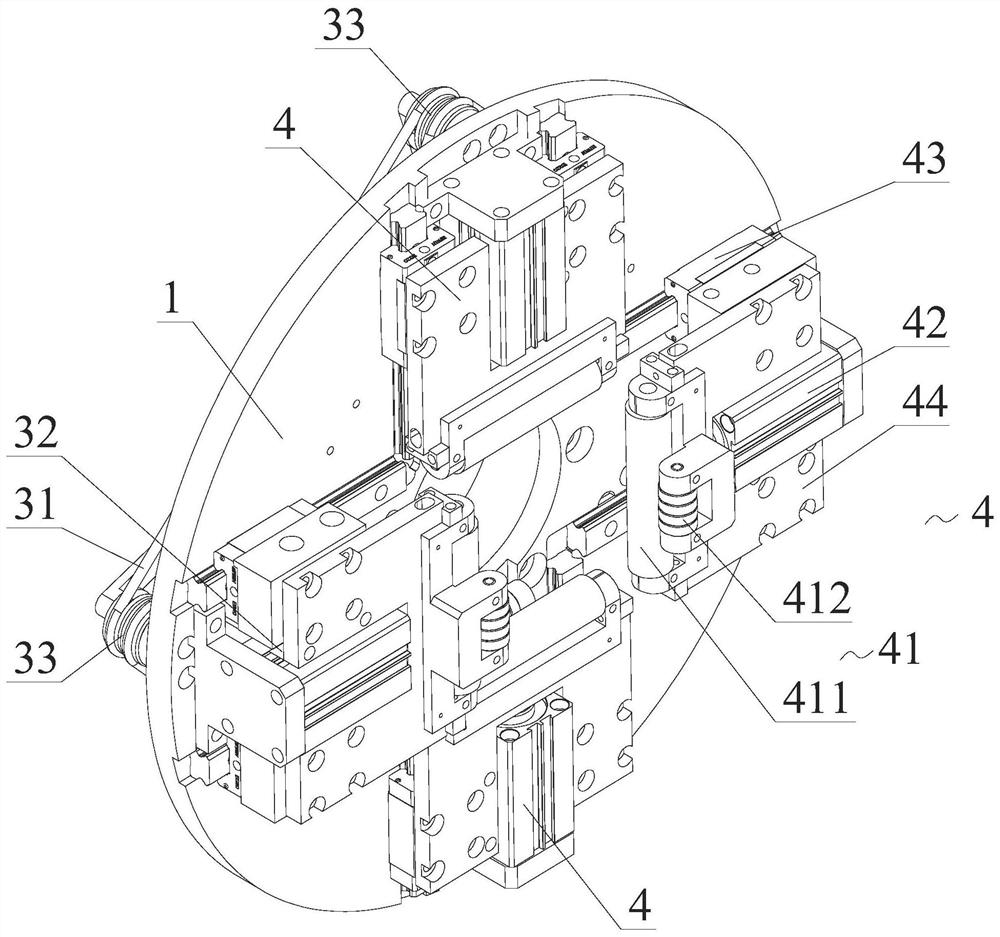

[0027] see Figure 1-4 As shown, a steel wire rope symmetrical linkage chuck includes a turntable body 1 and a positioning sleeve 2 supporting and fixing the turntable body 1. A wire rope assembly 3 is provided on the turntable body 1 on one side of the positioning sleeve 2. The turntable body The other side of 1 is provided with more than two groups of automatic jaw parts 4, and each group of automatic jaw parts 4 is provided with a guide pressure roller 41 and a driving cylinder 42, and the driving cylinder 42 drives the guide pressure roller 41 Reciprocating movement clamps or loosens the workpiece; the steel wire rope assembly 3 is provided with a tensioned steel wire rope 31, and a linkage 32 is fixed on the steel wire rope 31, and the guide pressure wheels in each group of the automatic jaw parts 4 41 are respectively connected with one o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com