High-precision automatic welding machine

An automatic welding machine and high-precision technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inability to weld, performance deterioration, etc., and achieve simple structure, convenient positioning, and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

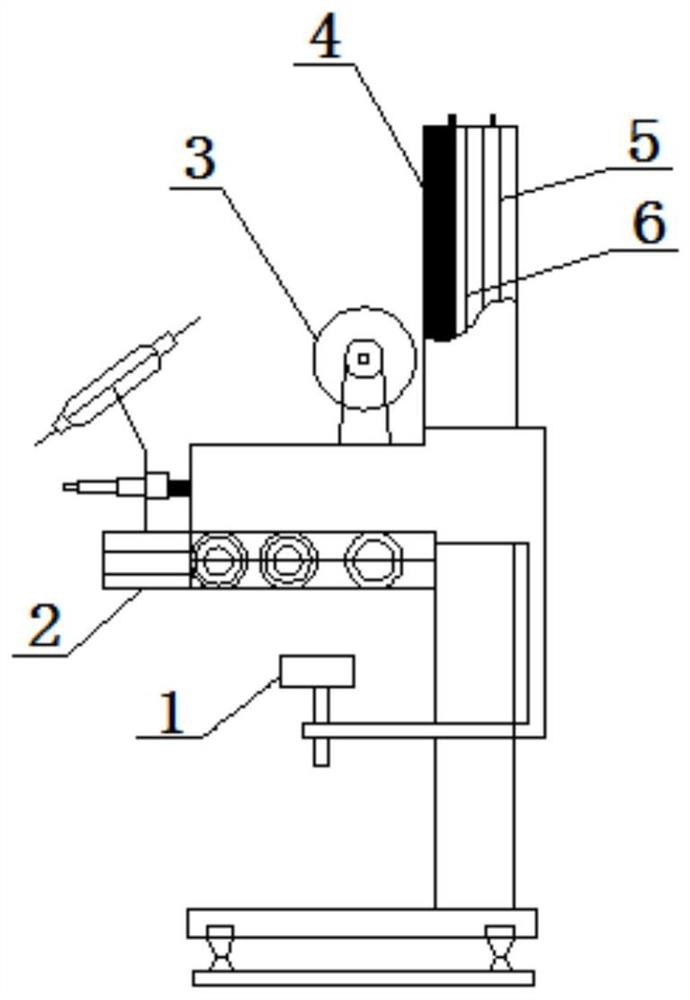

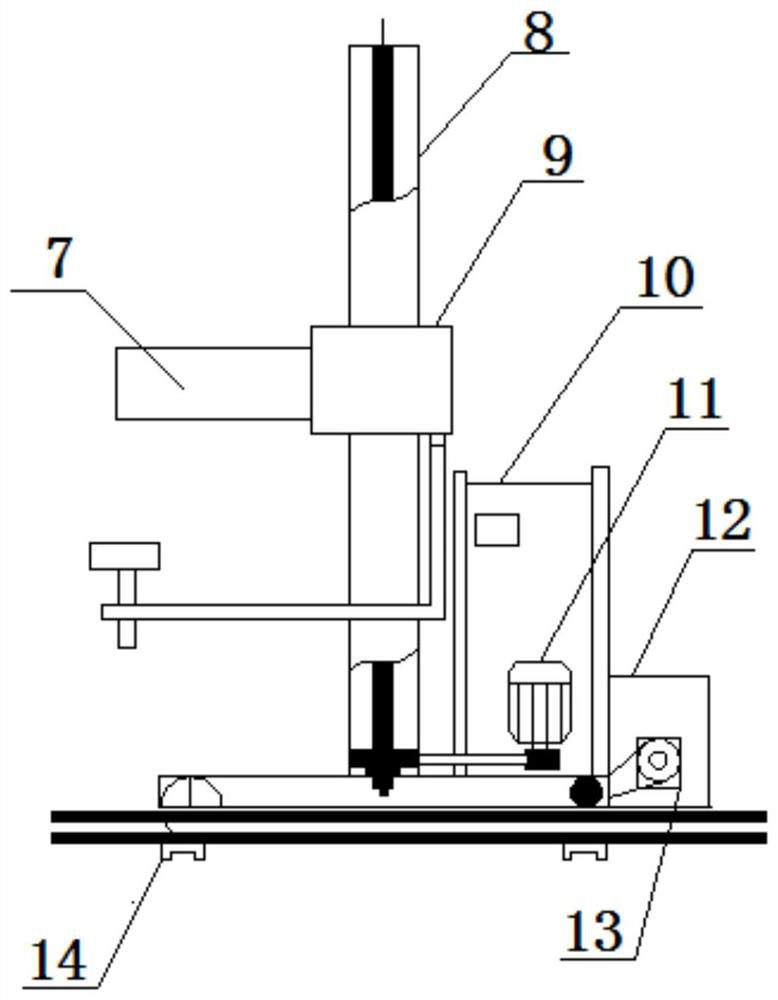

[0020] Example: such as Figure 1-2 As shown, a high-precision automatic welding machine of the present invention includes a chair 1, the upper end of the chair 1 is provided with a touch button board 2 and the touch button board 2 is installed on one end of the electrical control box 7; the electrical control box (7) The top is provided with a large roulette 3; one side of the large roulette 3 is provided with a hard guide rail 4; one side of the hard guide rail 4 is provided with a screw 5; one side of the screw 5 is equipped with a column 6; The column 6 is arranged inside the square steel pipe 8 and the square steel pipe 8 runs through the inside of the welding head workbench 9; the side of the square steel pipe 8 is provided with a motor and electrical transformer 10, and the inside of the motor and electrical transformer 10 is provided with a welding machine workbench lifting motor 11; An electric box 12 is arranged on one side of the welding machine workbench lifting mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com