Sweet potato cutting device for sweet potato powder production

A cutting device and technology of sweet potato flour, applied in metal processing, etc., can solve the problems of manpower consumption, low efficiency, and inability to improve production efficiency, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

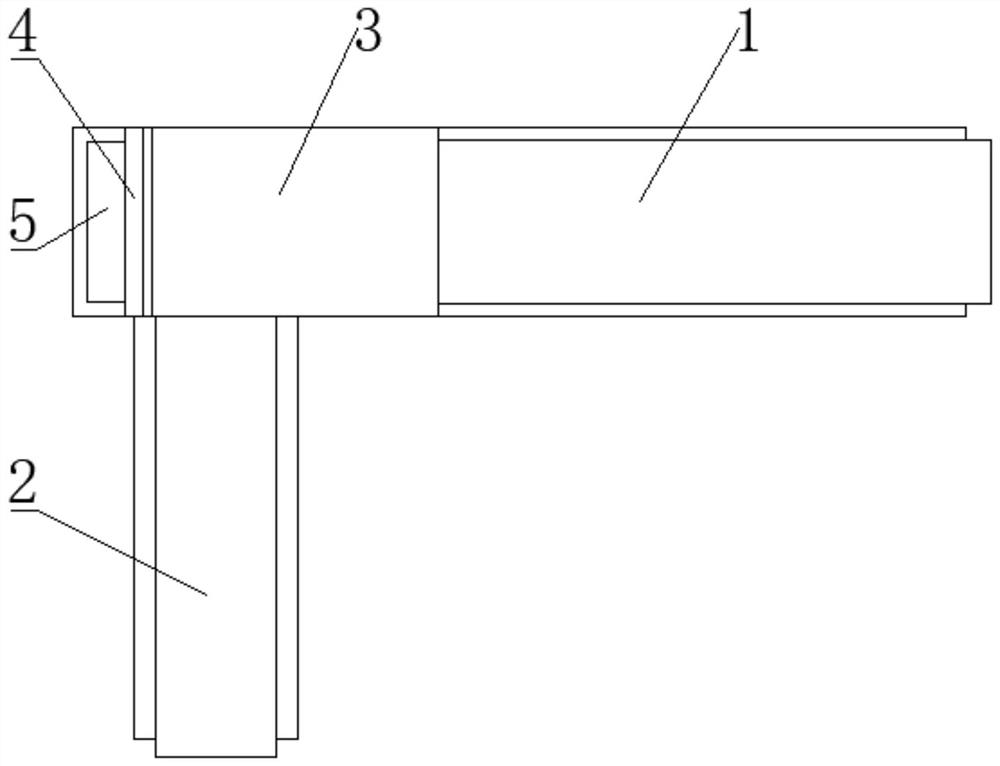

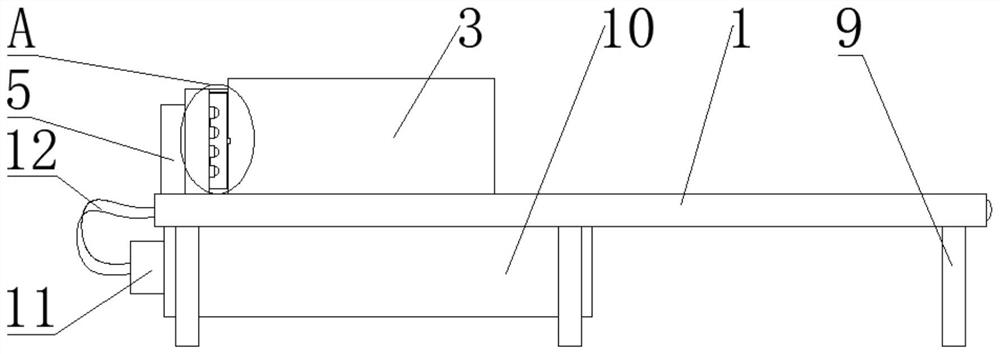

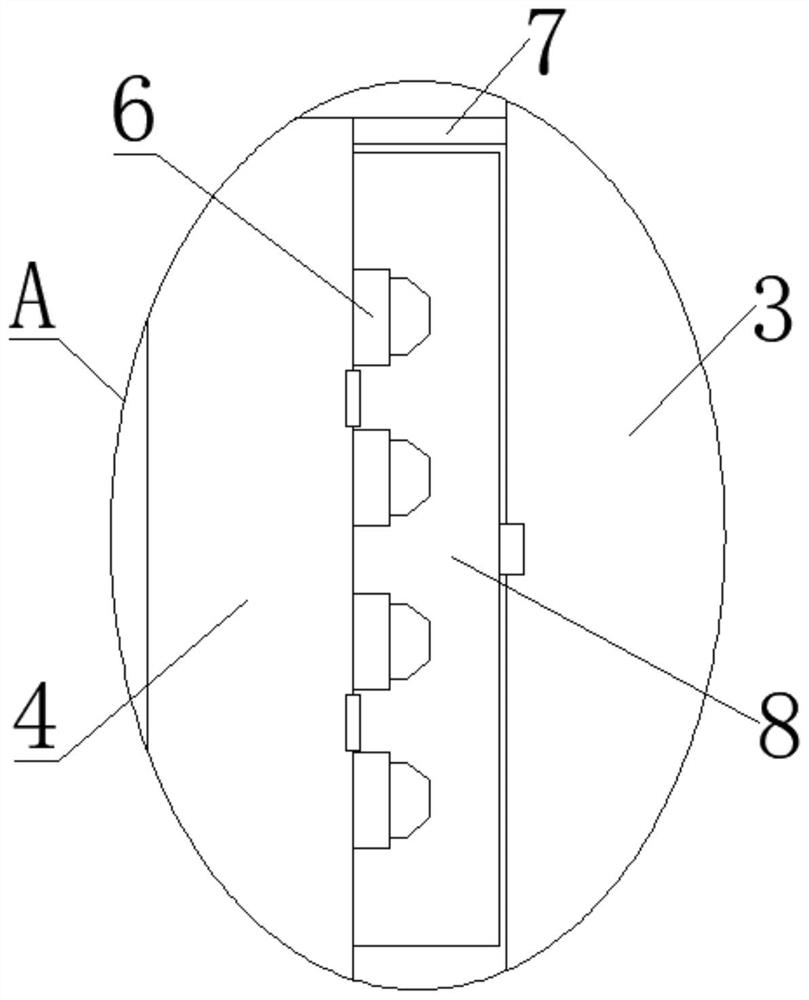

[0031] Such as Figure 1-6 Shown, the embodiment of the present invention provides a kind of sweet potato cutting device for production of sweet potato powder, comprises the first conveyor belt structure 1 and the second conveyor belt structure 2, end-to-end arrangement is arranged between the first conveyor belt structure 1 and the second conveyor belt structure 2, for Drive the sweet potatoes through the second conveyor belt structure 2 and the first conveyor belt structure 1, the top of the first conveyor belt structure 1 is fixedly connected with the cutting frame 3, the inner bottom of the cutting frame 3 is fixedly connected with the bottom carrying plate 15, and the top of the bottom carrying plate 15 passes through The adjustment mounting part 17 is fixedly connected with two groups of relative guide plates 18, which are used to ensure that sweet potatoes are cut vertically, and the inner side of the cutting frame 3 is fixedly connected with two groups of relative mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com