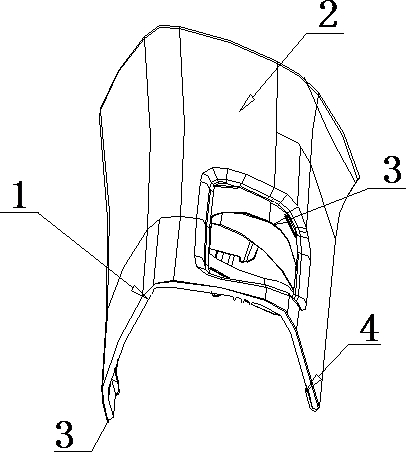

Automatic production line for producing automobile injection-molded coated products

A product and coating technology, applied in the direction of coating, etc., can solve the problems of low product pass rate, long production cycle, long process flow, etc., and achieve the effect of reducing plant occupation, improving production efficiency and pass rate, and realizing production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A detailed description will be given below of embodiments of the present invention. Although the present invention will be described and illustrated in conjunction with some specific embodiments, it should be noted that the present invention is not limited to these embodiments. On the contrary, any modification or equivalent replacement made to the present invention shall be included in the scope of the claims of the present invention.

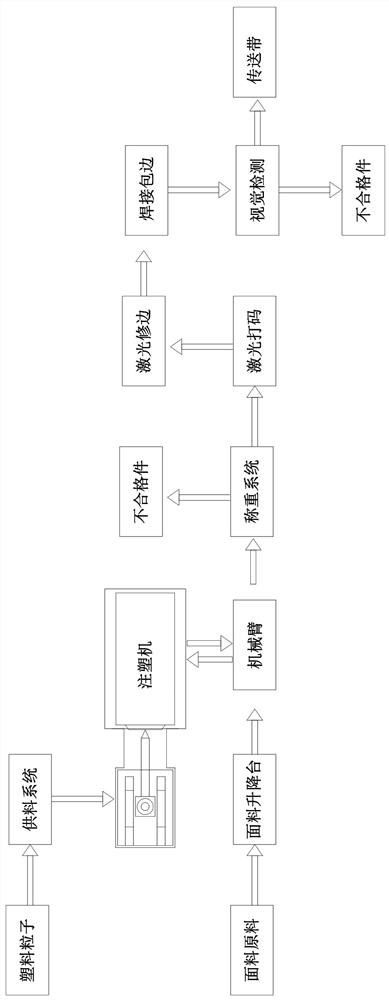

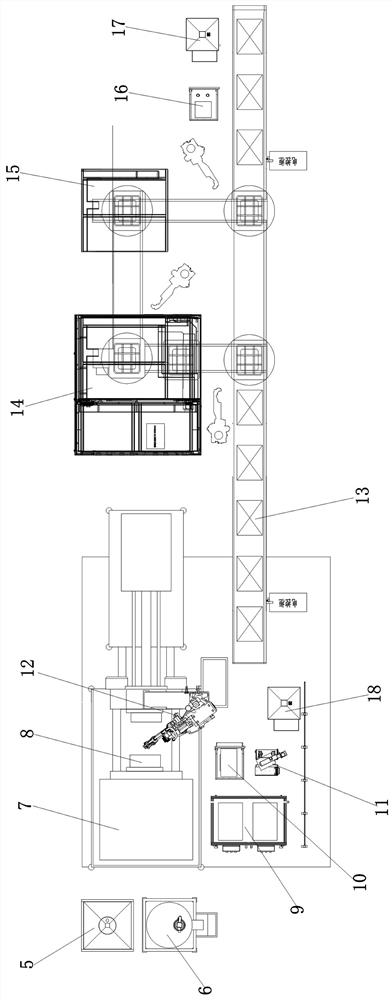

[0017] An automatic production line for the production of automotive injection molding and cladding products, including automatic feeding system, injection molding machine, low-pressure injection mold, weighing system, laser coding traceability system, multiple sets of flexible robotic arms, laser cutting equipment, automation package Edge welding equipment, visual inspection equipment. The corresponding process flow is as figure 2 As shown, the plastic particles are supplied to the injection molding machine through the feeding syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com