Dust rod pressing machine for tobacco processing

The technology of a rod pressing machine and dust is applied in the direction of material forming presses, presses, manufacturing tools, etc., which can solve the problems of tobacco dust rods being difficult to loosen, and the extrusion effect of tobacco dust rods cannot be achieved, and achieves good molding effect, Good practical effect, reduce the effect of driving mechanism and related control mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

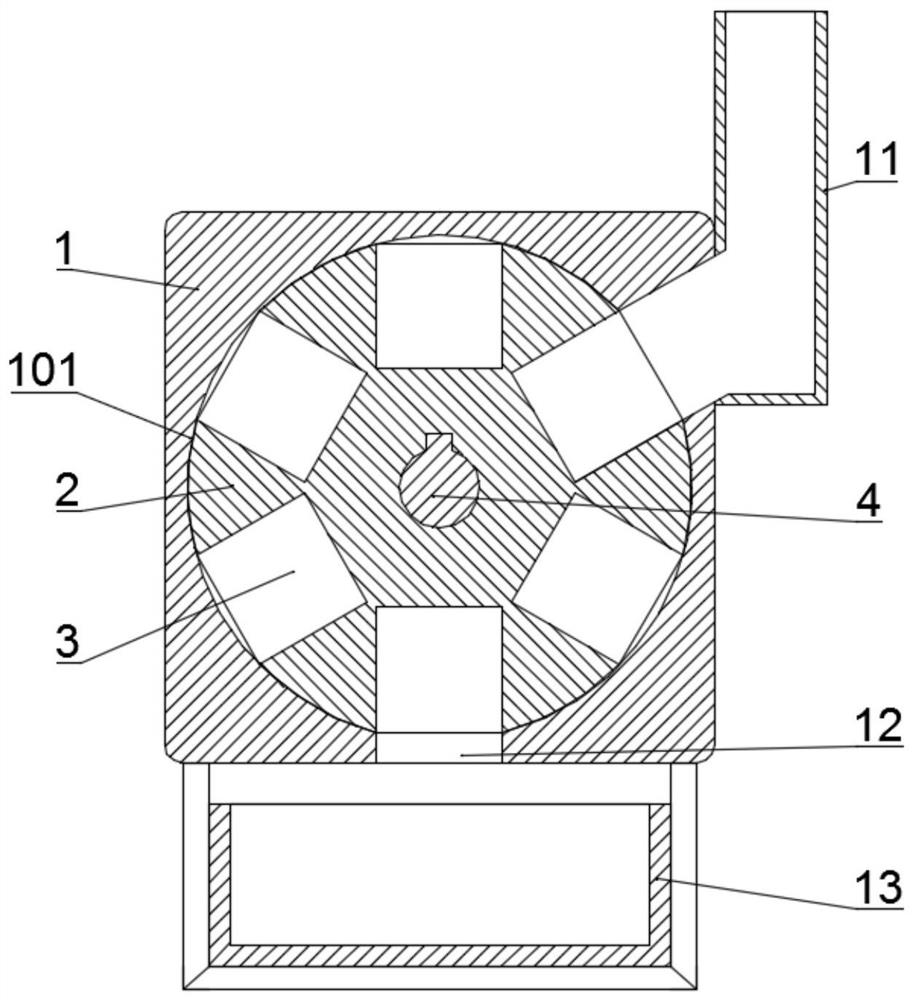

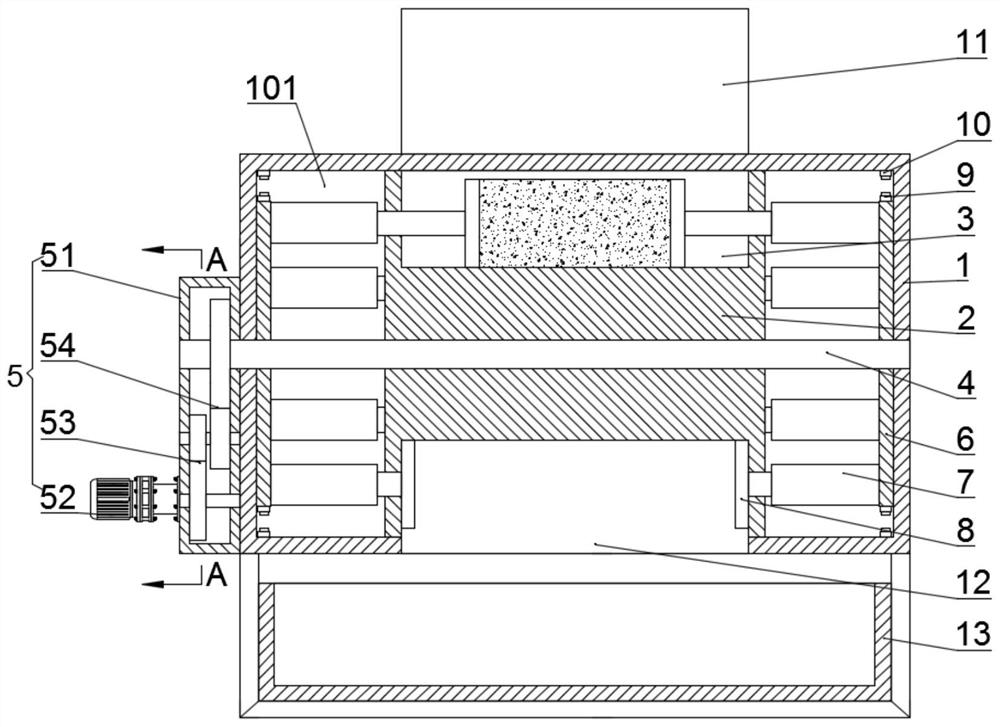

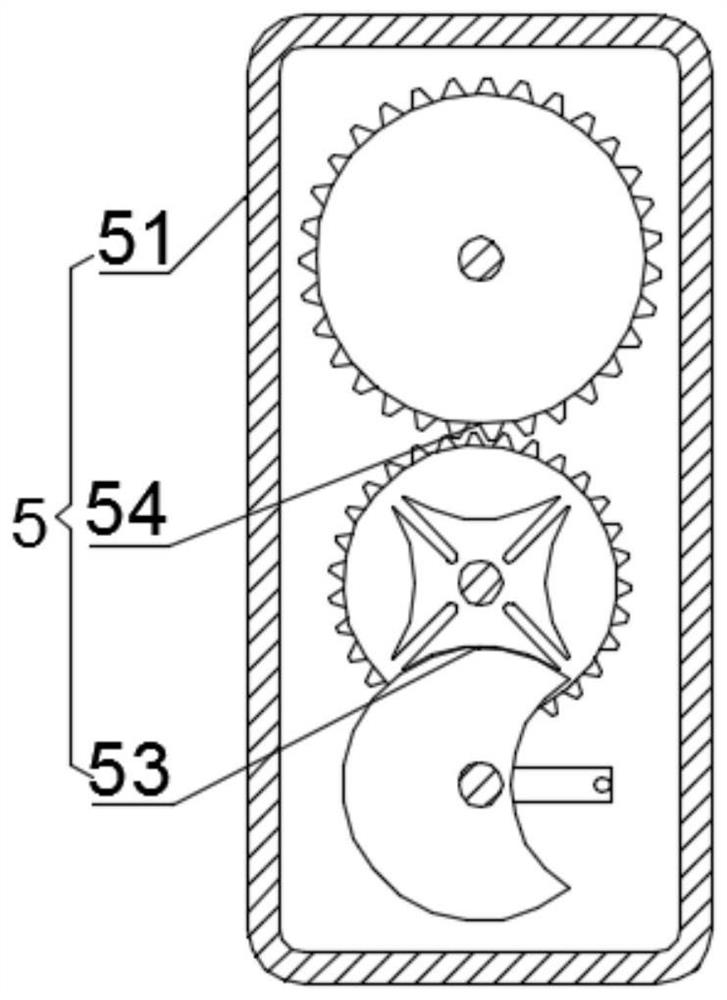

[0029] Such as Figure 1-4 As shown, a dust press machine for tobacco processing includes a housing 1, a cylindrical cavity 101 is opened inside the housing 1, and a cylindrical cavity 101 is arranged inside the cylindrical cavity 101. The rotating cylinder 2 arranged coaxially, and the circumferential surface of the rotating cylinder 2 is arranged in contact with the inner wall of the cylindrical cavity 101, and the installation hole of the rotating cylinder 2 is provided with a main shaft 4, and the main shaft 4 is connected with the housing The side wall of 1 is rotated and installed, and one end of the main shaft 4 is connected by a rotating drive mechanism 5. The circumferential surface of the rotating cylinder 2 is uniformly provided with a receiving groove 3, and the upper side of the side wall of the housing 1 is connected with an inlet The feed pipe 11, the lower side wall of the housing 1 is provided with a discharge port 12, when the rotating cylinder 2 rotates, the...

Embodiment 2

[0038] Such as Figure 1-4 As shown, a dust press machine for tobacco processing includes a housing 1, a cylindrical cavity 101 is opened inside the housing 1, and a cylindrical cavity 101 is arranged inside the cylindrical cavity 101. The rotating cylinder 2 arranged coaxially, and the circumferential surface of the rotating cylinder 2 is arranged in contact with the inner wall of the cylindrical cavity 101, and the installation hole of the rotating cylinder 2 is provided with a main shaft 4, and the main shaft 4 is connected with the housing The side wall of 1 is rotated and installed, and one end of the main shaft 4 is connected by a rotating drive mechanism 5. The circumferential surface of the rotating cylinder 2 is uniformly provided with a receiving groove 3, and the upper side of the side wall of the housing 1 is connected with an inlet The feed pipe 11, the lower side wall of the housing 1 is provided with a discharge port 12, when the rotating cylinder 2 rotates, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com