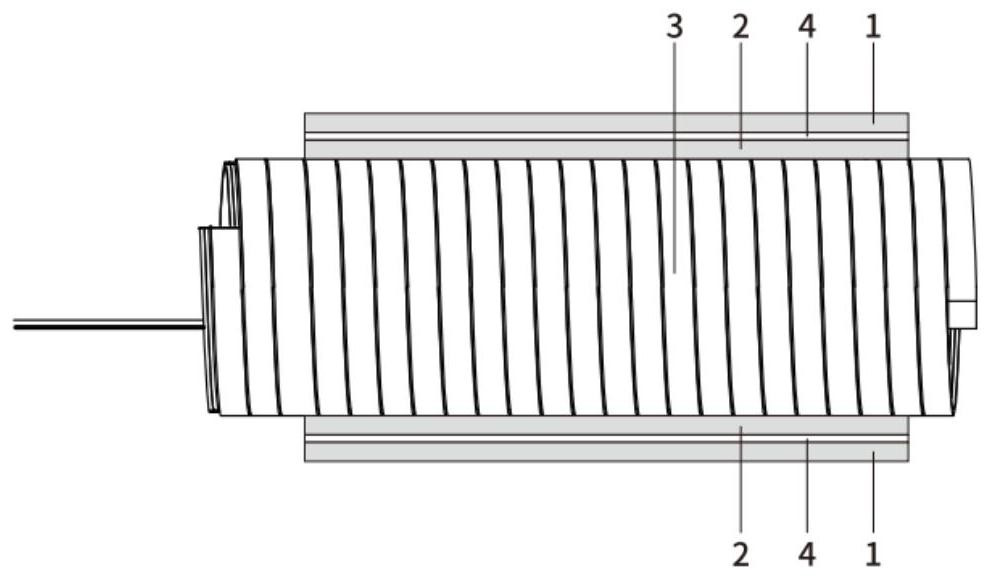

Double-layer cold-shrink bushing, preparation method and application thereof

A cold-shrinkable sleeve and a cold-shrinkable tube technology are applied in the field of double-layer cold-shrinkable sleeves and their preparation, which can solve the problems of poor physical and mechanical properties, poor retraction performance, easy generation of water storage, etc., and achieve good low temperature resistance. , Improve physical and mechanical properties, enhance waterproof sealing effect and life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0037] Unless otherwise specified, the experimental methods used in the following examples are conventional methods; the reagents and materials used in the following examples, unless otherwise specified, can be obtained from commercial sources.

[0038]The test method or standard used in the following examples is: the test standard of tensile strength is ASTM D412-15a Method A; the test standard of elongation at break is ASTM D412-15a Method A; the test standard of tear strength is ASTM ...

Embodiment 1

[0040] A: Select a silicone cold shrink tube with an inner diameter of 7mm and a thickness of 2.5mm (expansion ratio is 4.5 times), and apply vinyl silane surface treatment agent evenly on the outer surface of the silicone cold shrink tube, and then treat the outer surface of the silicone cold shrink tube. surface treatment;

[0041] B: Evenly coat the styrene-butadiene rubber adhesive on the outer surface of the silicone cold shrink tube;

[0042] C: Select an ethylene-propylene rubber cold-shrinkable tube with an inner diameter of 8 mm and a thickness of 2.5 mm (expansion ratio is 4.5 times), and expand the ethylene-propylene rubber cold-shrinkable tube to the silicone cold-shrinkable tube prepared in the above step B through an expansion machine to prepare a Double-layer tubing with an adhesive interface layer;

[0043] D: Cut the double-layer tube prepared in the above step C, and cut it according to the required length, and ensure that the length of the silicone cold shr...

Embodiment 2

[0054] A: Select a silicone cold shrink tube with an inner diameter of 9mm and a thickness of 3.0mm (expansion ratio is 4.5 times), and apply vinyl silane surface treatment agent evenly on the outer surface of the silicone cold shrink tube, and then treat the outer surface of the silicone cold shrink tube. surface treatment;

[0055] B: Evenly coat the styrene-butadiene rubber adhesive on the outer surface of the silicone cold shrink tube;

[0056] C: Select an ethylene-propylene rubber cold-shrinkable tube with an inner diameter of 10mm and a thickness of 3.0mm (expansion ratio is 4.5 times), and expand the ethylene-propylene rubber cold-shrinkable tube to the silicone cold-shrinkable tube prepared in the above step B through an expansion machine to prepare a Double-layer tubing with an adhesive interface layer;

[0057] D: Cut the double-layer tube prepared in the above step C, and cut it according to the required length, and ensure that the length of the silicone cold shri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com